Alcohol Filling Machine Automatic Liquid Filling Machine

Model: LFZ-08

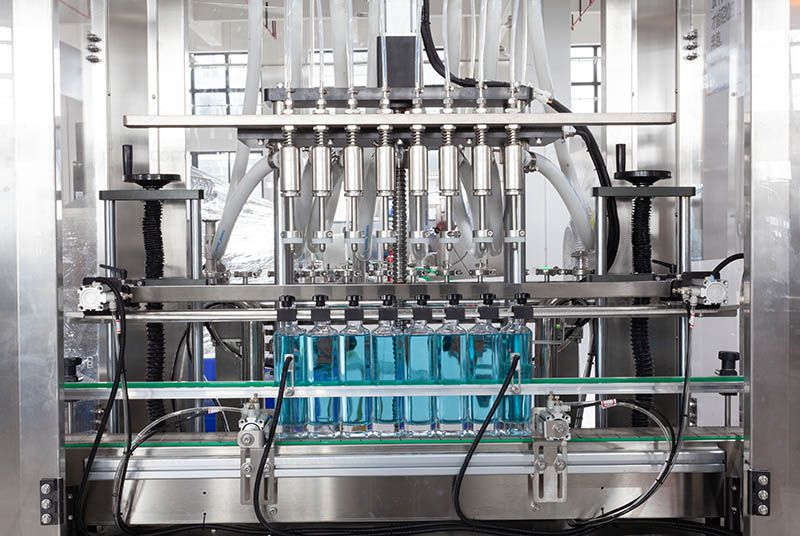

By creating a mild pressure difference inside each container, the system allows liquids to flow smoothly and stop precisely at the preset liquid level.

Application:

The machine is suitable for filling various liquid and semi-liquid products in food, beverage, cosmetic, and household chemical industries. It handles cocktails, syrups, alcohol, vinegar, sauces, shampoo, detergent liquids, and other bottled products.

Application:

The machine is suitable for filling various liquid and semi-liquid products in food, beverage, cosmetic, and household chemical industries. It handles cocktails, syrups, alcohol, vinegar, sauces, shampoo, detergent liquids, and other bottled products.

Package Type:

This 8 head liquid filling machine suitable for a range of containers, including PET HDPE as well as PP glass bottles, plastic bottles and chemical-resistant bottles typically used for chemical-resistant pesticides as well as industrial fluids.

Suitable Products:

The automatic liquid filling machine is designed for smooth, low-to-medium viscosity liquids that require accurate dosing. It is suitable for multiple industries, including food & beverage, health & nutrition, and cosmetics & personal care.

1. Food & Beverage Industry: Alcoholic Beverages, Sauces, Cooking Oils, Dairy Products.

2. Health & Nutrition Industry: Liquid Dietary Supplements, Plant-Based Beverages, Nutritional Syrups, Oral Liquid Medicines.

3. Cosmetic & Personal Care Industry: Perfumes, Essential Oils, Liquid Skincare, Shampoo.

Process Workflow:

1. Bottle Feeding - Bottles which have been empty are moved to the right position and then transferred to the station for refilling, in constant and stable order.

2. Sensors locate bottles - confirm the alignment and presence in each of the bottles.

3. Vacuum-Assisted Filling - 8 heads used for filling use negative pressure to push liquid out of the bottles easily.

4. Bottle Discharge - bottles that have been filled are taken to the station for capping, labeling or packaging downstream

Machine Model | LFZ-08 | |||

Voltage | 220V 50hz | |||

Filling Head | 8 Heads | |||

Filling Range | 50-1000ml(Customizable) | |||

Filling Speed | 15-25 bottles/min | |||

Filling Accuracy | ±1% | |||

Air Pressure | 0.6-0.8Mpa | |||

Power | 2KW | |||

Machine Material | Stainless Steel | |||

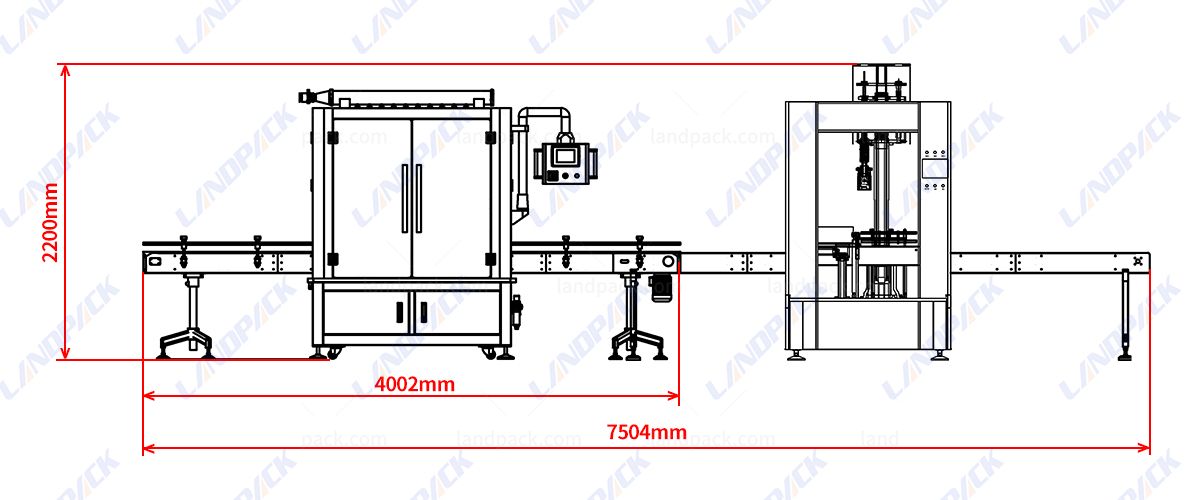

Machine Size | L4000*W1320*H2090(mm) | |||

Machine Weight | 650 kg | |||

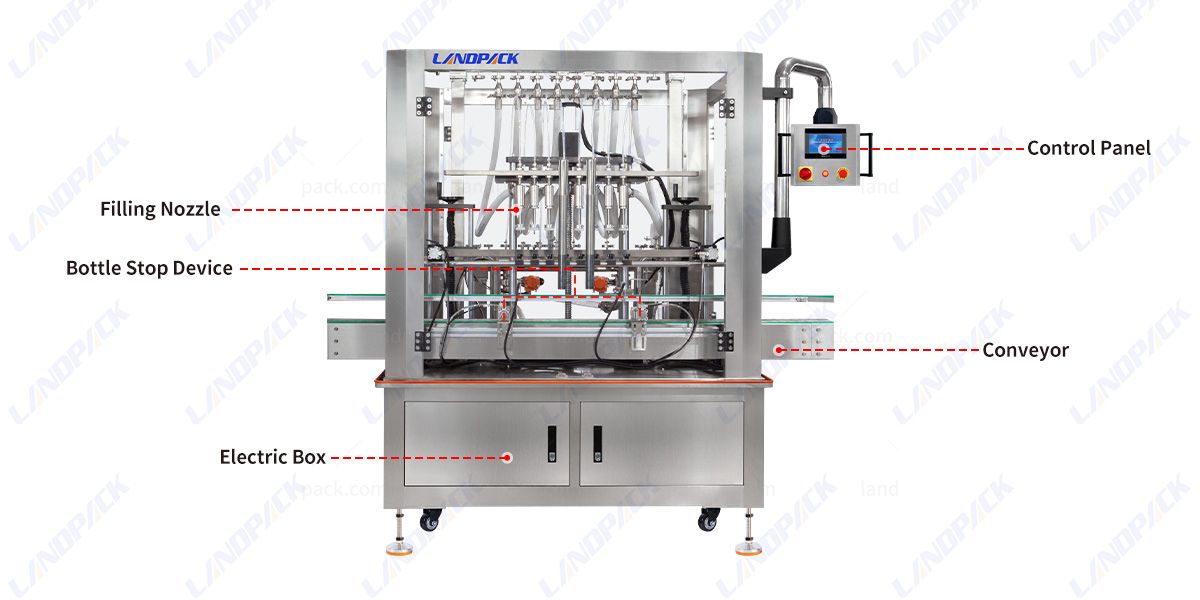

Machine Key Components:

1. Filling Nozzle

2. Control Panel

3. Bottle Stop Device

4. Conveyor

5. Electric Box

Feature:

Vacuum Equal-Level Filling System Uses a constant-level technique to ensure that each bottle has the same height in liquid. |  |

| High-Efficiency 8-Station Filling Platform Eight filling points synchronized to operate in continuous time increasing production capacity. |

Adaptive Nozzle Design for Complex Liquids Nozzles automatically adjust the depth of immersion to limit splashing, bubbles and turbulence. |  |

| Precise Bottle Positioning & Intelligent Detection The filling machine combines bottles guiding rails as well as photoelectric tracking and auto-stop protection, which ensures the correct alignment prior to filling. |

Corrosion-Resistant Construction for Harsh Media The key contact parts are manufactured of anti-corrosive material that are suitable for liquids with chemical components |  |

| Tool-Free Changeover for Multiple Bottle Formats Operators are able to switch between various containers' heights and diameters in a matter of minutes |

User-Friendly Control Interface PLC equipped with a touchscreen offers continuous monitoring in real time, alarms for faults and memory for parameters |  |

Get Price & More Detail