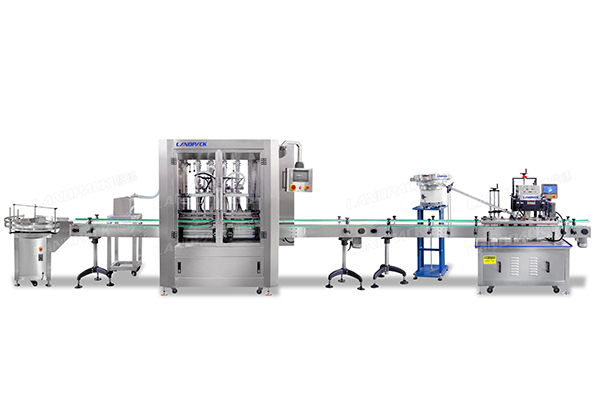

Automatic Follow-Up Type High Speed Filling Machine

Model: LF-LZ-G2

Application:

It is suitable for filling liquid pastes in medicine, food, daily chemicals, pesticides, and fine chemicals.

Advantages:

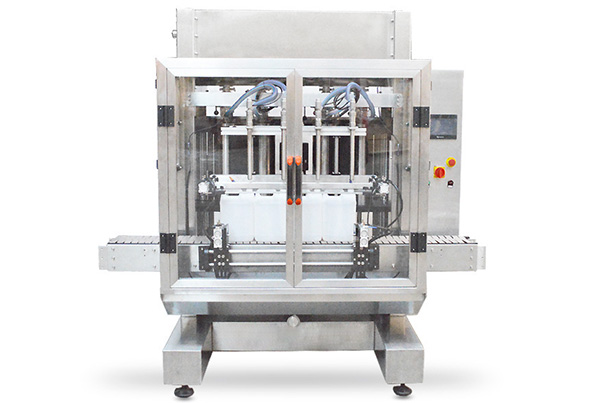

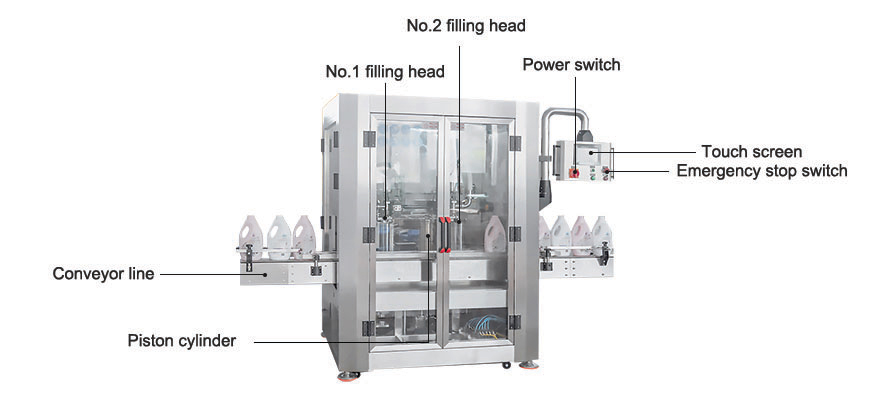

Adopting the principle of plunger quantitative filling, bottle feeding, positioning, filling, and bottle discharge are automatically controlled by PLC, which conforms to GMP standards.

Application:

Automatic follow-up type high-speed filling machine is suitable for filling liquid pastes in medicine, food, daily chemicals, pesticides, and fine chemicals.

Examples: Such as Cosmetics, laundry detergent, shampoo, shower gel, hand soap, sauce, lubricating oil, etc.

Packaging Type: It is suitable for bottles with different shapes, heights, and capacities. It only takes a few minutes to complete the debugging

Packaging Material: Glass, Metal, Paper, Plastic, Wood, And Others

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples:

How It Works:

At the filling station of the filling machine, since the bottle body is continuously transported forward, the tracking filling component requires four functional actions, namely, tracking down insertion into the bottle mouth, tracking filling, rapid ascent, and rapid return. The functional actions can be decomposed into horizontal tracking movement and vertical lifting movement, and the four functional actions constitute a movement cycle.

| Filling Capacity(ML) | 100-1000ml (customizable) |

| Speed(BPM) | 30-38Bottles/minute (decided according to the filling volume and materials) |

| Power Supply(VAC) | 380V/50HZ |

| Motor Power(KW) | 3.0 |

| Air Consumption(MIN) | 4KGS×30LITER |

| Dimensions | 2000*1400*1900mm |

| Weight(KG) | 580 |

A. Efficient filling

1. Follow-up high-speed filling machine, using sensors to accurately find bottles, follow-up filling, no stop in the production process, about 500ml capacity can fill 30-40 bottles per minute.

2. The traditional multi-head automatic filling machine is expensive, the bottle must be stopped during the production process, and the filling speed is slow.

B. Intelligent tuning

1. The follow-up high-speed filling machine can complete the debugging for bottles of different shapes, different heights, and different capacities in just a few minutes and enter the next wave of production. It completely solves the problems caused by a wide variety of products, a small number of single products, and frequent adjustments. Time-consuming and laborious problem.

2. The traditional automatic filling machine needs to be debugged repeatedly before it can be put into production again, which is time-consuming and labor-intensive, and it is not applicable to some special-shaped bottles at all.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail