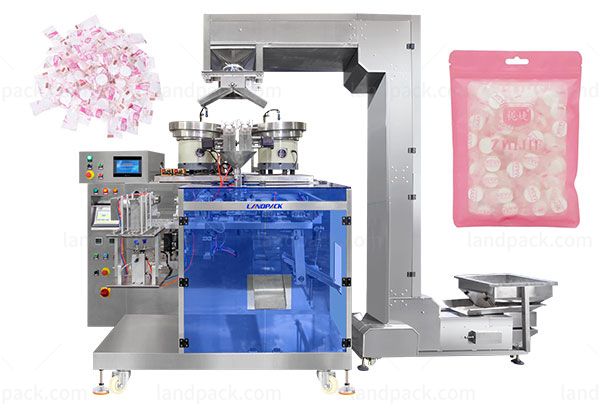

Automatic Rotary Pouch Packing Machine For Candy Toffee Confectionery

Model: LD-8260

It' s a versatile solution for companies that want attractive, retail-ready packaging with fast changeovers and high-speed performance. With a speed of up to 60 pouches per minute, it ensures efficient, accurate, and visually appealing retail-ready packaging.

Application:

Our high-performance 8-station pouch packaging machine is designed for secondary packaging of pre-packed products such as snacks, candies, chocolates, biscuits, and other small items.

What is a rotary pouch packaging machine?

A rotary pouch packaging machine is an automated system that fills and seals pre-made pouches in a circular, rotating process. It typically features multiple working stations arranged around a rotary indexing table, where each station performs a specific function such as pouch feeding, opening, filling, sealing, and discharging.

Application:

This type of machine is widely used for packaging snacks, powders, granules, liquids, and small pre-packed items, offering advantages like:

- Baking: Cakes, Chocolate Cakes, Puff Pastry, Filled Muffins

- Candy & Snacks: Chewy Caramels, Gummy Bears, Wafer Crackers, Nut & Seed Mix

- Others: Pet Food, Frozen Foods, or Frozen Meat, daily Chemicals (such as cups for mouthwash)

Flexible compatibility with a variety of kinds of pouches and products. The machine ensures precise filling, reliable sealing, and excellent product presentation, making it ideal for both primary and secondary packaging needs.

Package Type:

The Rotary Pouch Packing Machine works seamlessly with a wide range of premade pouch formats such as zipper bags, stand-up pouches, flat pouches, and M-type pouches. These versatile packaging styles provide strong product protection, secure sealing, and longer freshness, while also boosting visual impact on store shelves.

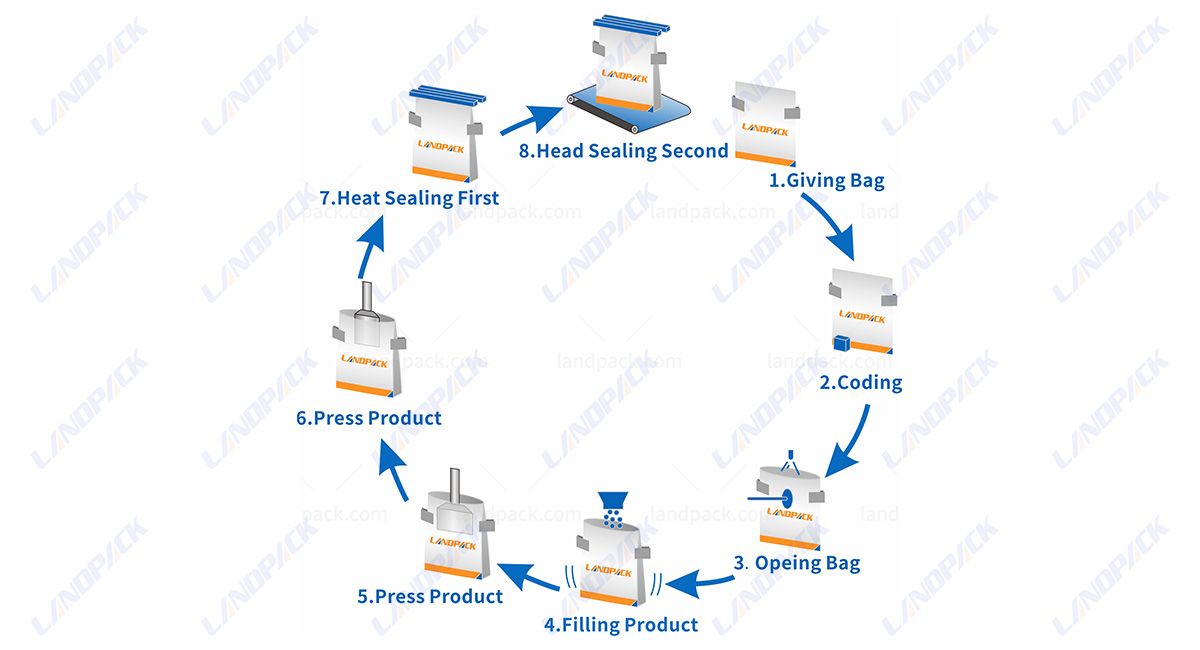

Workflow:

Bag Giving – The premade pouch is delivered to the machine.

Coding – The pouch is marked with date, batch code, or other information.

Bag Opening – The machine opens the pouch for filling.

Filling Product – The target product (powder, granules, liquid, or snacks) is filled into the pouch.

First Pressing – The pouch is pressed to settle the product inside.

Second Pressing – Ensures the product is evenly positioned for sealing.

First Heat Sealing – The pouch is sealed securely with heat.

Second Heat Sealing – This seal is reinforced to provide extra protection, assuring the package is airtight as well as secure.

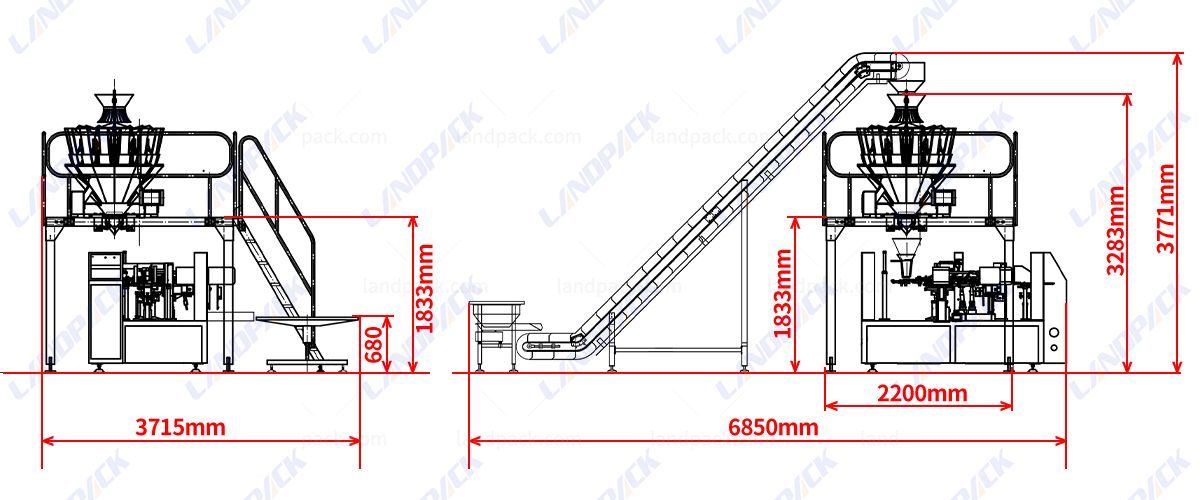

| Type | LD-8230 | LD-8260 | LD-8300 | LD-8400 |

| Bag Type | 3-side, 4 side sealing bag, doypack, box pouch, zipper pouch, stand up pouch, side gusset bag, etc. | |||

| Bag Size | 150-380mm*80-230mm (L*W) | 150-380mm/140-260mm (L*W) | 150-430mm/180-300mm (L*W) | 200-500mm/270-400mm (L*W) |

| Filling Range | 10g-1000g | 1500g | 2000g | 3000g |

| Packing Speed | 20-60 bags/min | 20-50 bags/min | 10-40 bags/min | 10-25 bags/min |

| Voltage | Standard AC380V+10%, three-phase 50HZ; | |||

| Total Power | 3.75KW | 3.75KW | 3.85KW | 4.5KW |

| Air Consumption | 0.4m³/min | |||

| Dimensions | 1740*1380*1450mm(L*W*H) | 2460*1830*1460mm(L*W*H) | 2260*2200*1520mm(L*W*H) | |

| Machine Weight | 1300KG | 1300KG | 1700KG | 2000KG |

Machine Key Components:

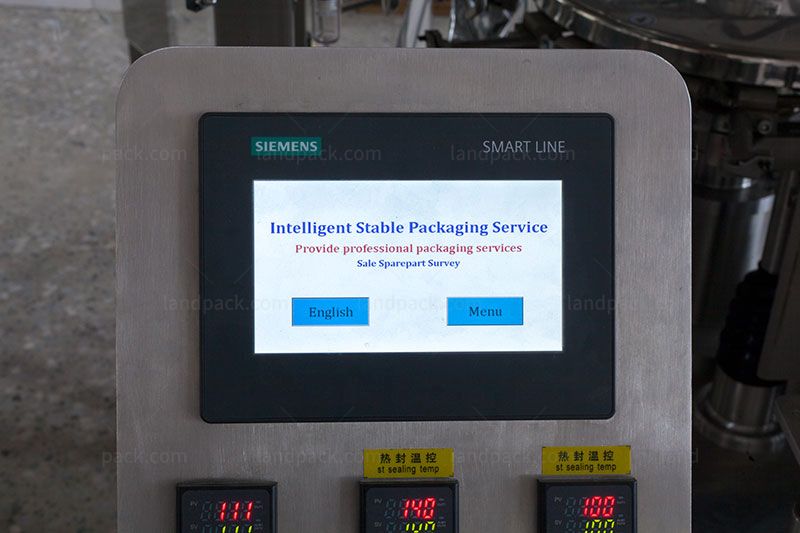

* Control Panel

* Vibration hopper

* Feeding conveyor

* Multi-head electrical weigher

* Platform

* Rotary packing machine

* Output collecting turntable

Control Panel Touch screen that is user-friendly with a smart interface, which allows for rapid parameter adjustments and real-time monitoring. |  |

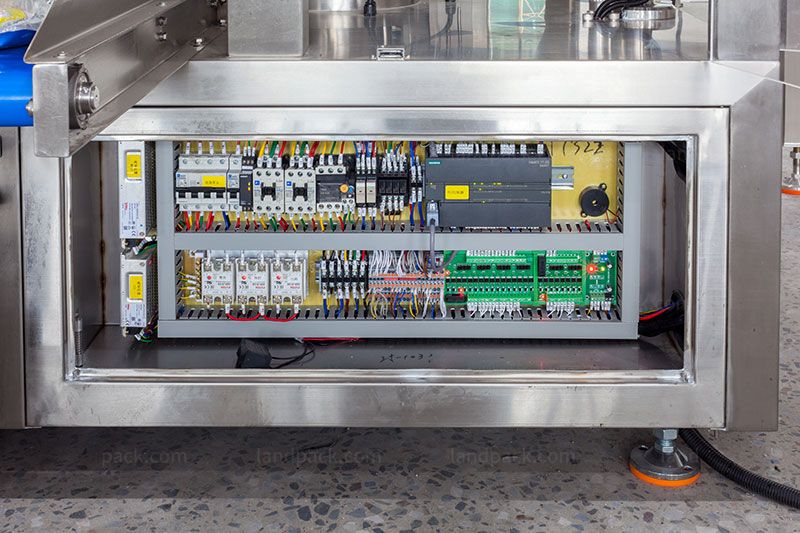

| Electrical Box An integrated electrical system, with reliable PLC control, which ensures the reliability and efficiency of operation. |

Vibration Hopper Keeps materials flowing smoothly and prevents clogging during feeding. |  |

| Feeding Conveyor Automatically transfers products to the weighing system with steady and hygienic handling. |

Multi-head Weigher High-precision weighing system for accurate portioning, reducing material waste. |  |

| Rotary Packing Machine Core unit for pouch opening, filling, sealing, and coding with stable speed up to 60 bags/min. |

Output Collecting Turntable Efficient dosing of solid or granular products such as beans, meat cubes, or pickles. |  |

Get Price & More Detail