Fully Automatic Multi Lane Chutney Sachet Counting And Packing Machine

Model: LD-480Y

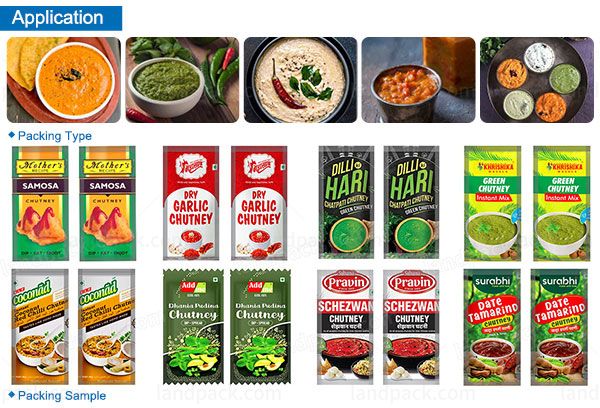

Application:

This machine is suitable for automatic packaging of various liquid materials in the food, chemical, daily chemical and other industries, such as: ketchup, chutney, honey, soy sauce, chili sauce, tartar sauce, fruit juice, cream, mayonnaise, jam, chocolate sauce, liquid cheese, laundry detergent, etc.

Advantages:

The product adopts advanced general control technology, can set the filling amount and filling speed through the touch screen.

Application:

This machine is suitable for automatic packaging of various liquid materials in the food, chemical, daily chemical and other industries, such as: ketchup, chutney, honey, soy sauce, chili sauce, tartar sauce, fruit juice, cream, mayonnaise, jam, chocolate sauce, liquid cheese, laundry detergent, etc.

Examples:

Chutney, syrup, peanut butter, chocolate sauce, ketchup, juice, shampoo, fruit juice, honey, jam, paste, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

Model | LD-480Y | LD-720Y | LD-960Y |

| Track Number | 4~6 Track | 4~10 Track | 4~12 Track |

| Filling Method | 1.Piston pump; 2.Peristaltic Pump | ||

| Capacity | Max.40 cycle/min | ||

| Sachet Size | L:45--120mm; W:35-60mm | L:45--120mm; W:35-90mm | L:45--120mm; W:35-120mm |

| Film Width & Thickness | Max.480mm;0.07-0.1mm | Max.720mm;0.07-0.1mm | Max.960mm;0.07-0.1mm |

| Sealing Type | 3/4 sides sealing | 3/4 sides sealing | 3/4 sides sealing |

| Cutting Type | 1. Straight Cutting; 2. Zig Zag Cutting; 3. Continuous Cutting | ||

| Air & Power | 0.8 mpa 0.8m³/min; 2.8kw | 0.8 mpa 0.8m³/min; 4.1kw | 0.8 mpa 0.8m³/min; 5.5kw |

| DIM & WT | 950*1470*1750mm; 300kg | 1153*1654*1750mm; 400kg | 1415*1686*2130mm; 500kg |

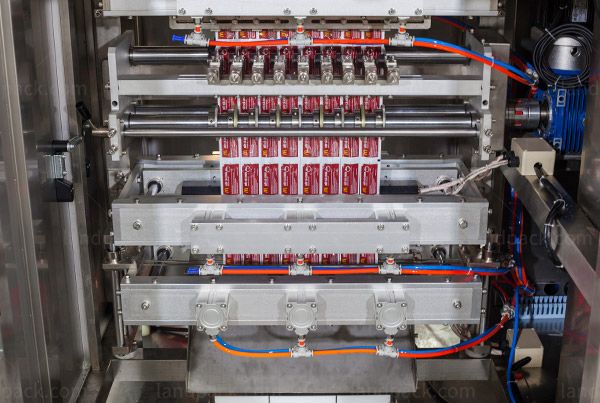

1. PLC control with stable reliable biaxial high accuracy output and color touch screen, bag-making, measuring, filling, printing,cutting , finished in one operation.

2. Separate circuit boxes for pneumatic control and power control. Noise is low, and the circuit is more stable.

3. Film-pulling with servo motor double belt: less pulling resistance, bag is formed in good shape with better appearance, belt is resistant to be worn-out.

4. External film releasing mechanism: simpler and easier installation of packing film.

5. Adjustment of bag deviation just needed to be controlled by the touch screen. Operation is very simple.

6. Close down type mechanism , defending powder into inside of machine.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail