Granular Packing Machine | Automatic Rice Premade Pouch Packaging Machine

Model: LDSP-160AS

Our horizontal bag packaging machine with precision linear scales delivers consistent weigh-to-bag performance for fine and free-flowing granules.

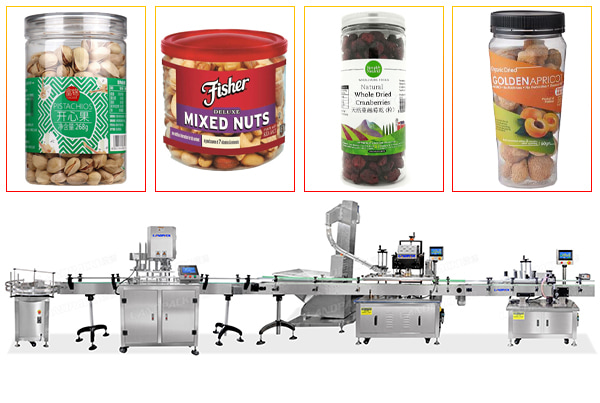

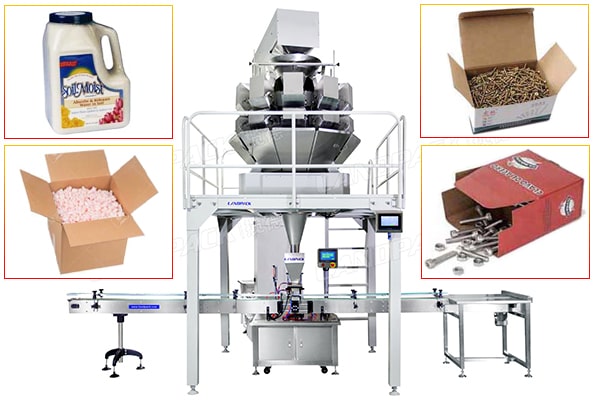

Application:

Engineered for granular producers, this packaging solution handles a wide range of materials from rice, grains, and seeds to sugar, salt and dry cereal pellets.

Application:

Our horizontal bag packaging machine with precision linear scales delivers consistent weigh-to-bag performance for fine and free-flowing granules. Built with stainless steel construction, reliable bag feeding and touch screen control, it ensures high-accuracy filling and stable sealing for rice, seeds, sugar, salt, beans, and other small particulate products.

Package Type:

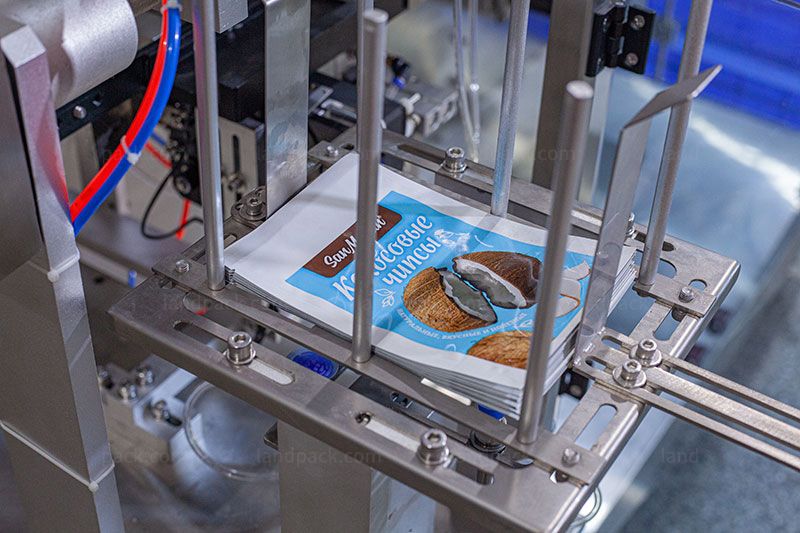

This automatic rice packing machine is compatible with a wide range of premade pouches, stand-up pouches, zipper pouches, gusset pouches, etc, ensuring clean filling, strong sealing, and high presentation quality for retail and wholesale packaging.

Suitable Products:

This rice packing machine was made to handle a large assortment of granular goods with stable accuracy and clean filling that making it suitable for both food and non-food sectors.

Grains & Cereals: Rice, Millet, Sorghum, Barley

Beans & Pulses: Red beans, Mung beans, Black beans, Chickpeas

Other Granular Products: Seeds, Sugar, Chicken bouillon granules, Laundry detergent

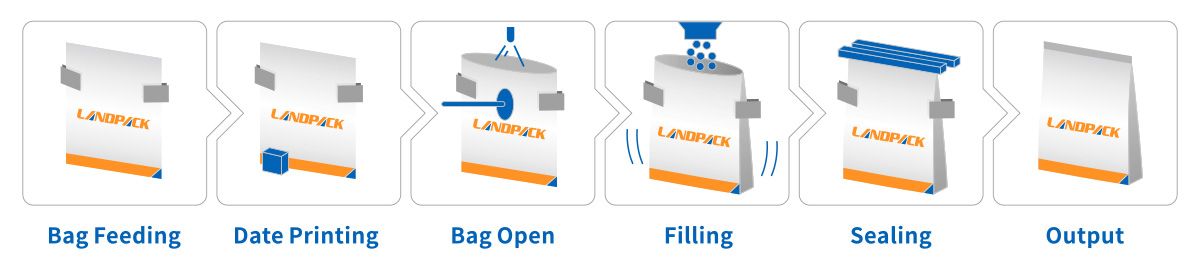

Workflow:

1. Bag Feeding: Premade pouches are automatically picked from the magazine and transferred to the gripper stations.

2. The Date Printer: The coding unit prints production dates, batch numbers, or required graphics onto the pouch prior to filling.

3. Bag Opening: Dual vacuum suction cups securely open each pouch and gently shape it to maintain stability during the filling process.

4. Filling: The dosing system dispenses an accurate amount of product—such as rice, grains, beans, powders, or other granular materials—into the opened pouch.

5. Sealing: The pouch opening is then heat- and pressure-sealed to form a strong, airtight closure.

6. Output: Finished pouches are discharged onto the output conveyor, ready for downstream packing or cartoning operations.

| Type | LDSP-160 | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, doypack, box pouch, zipper pouch, stand up pouch, stand up pouch with hole, kraft paper bag, side gusset bag, etc. | ||

| Bag Size | 110-230mm*80-160mm (L*W) | 100-210mm/110-320mm (L*W) | 140-260mm/160-380mm (L*W) |

| Filling Range | 20g-500g | 20g-1kg | 20g-1kg |

| Packing Speed | 20-45 bags/min | 20-50 bags/min | 20-40 bags/min |

| Machine weight | 800KG | 900KG | 900KG |

| Total Power | 2.5KW | 2.5KW | 2.5KW |

| Work Flow | 1. Giving bag, 2. Pick up the bag(coding), 3. Open the bag up and down, 4. Filling, 5. Heating sealing, 6. Output of product | ||

| Dimensions | 1750*1285*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) | 2140*1366*1360mm(L*W*H) |

Machine Key Components:

1. Vertical Feeding Bag Conveyor

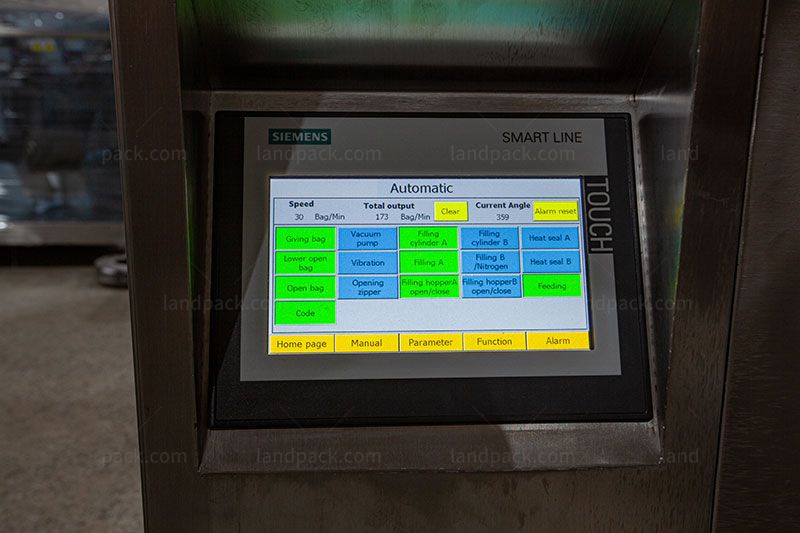

2. Control Panel

3. Storage Hopper

4. Automatic Vacuum Feeder Device

5. 4 Heads Linear Weigher

6. Filling Nozzle

7. Sealing Station

Feature:

Control Panel An intuitive touch screen interface that allows users to establish parameters, check the status of their machines in real-time, and control the machine's functions easily. It supports multi-language support and fast switchover of recipes. |  |

| Vertical Feeding Bag Conveyor Automatically lifts and delivers premade pouches to the bag grippers. Designed for smooth, stable bag feeding to ensure continuous operation without jamming. |

Automatic Vacuum Feeder + Storage Hopper Efficiently transfers granular materials such as rice, grains, or beans into the weighing system. Buffers and stabilizes product supply before weighing. |  |

| 4-Head Linear Weigher High-precision weighing system designed for granules. Each head measures independently, ensuring accurate weights and reducing product giveaway. Ideal for rice, grains, seeds, and similar products. |

Filling Nozzle Delivers product accurately into each pouch with minimal spillage. The design keeps the filling area clean and supports fast, stable filling for high-speed production. |  |

| Sealing Station Premade pouches are heat-sealed to ensure a high-quality seal. The adjustable temperature and pressure settings assure compatibility with different pouch materials such as zipper bags, stand-up pouches and flat bags. |

Get Price & More Detail