Application:

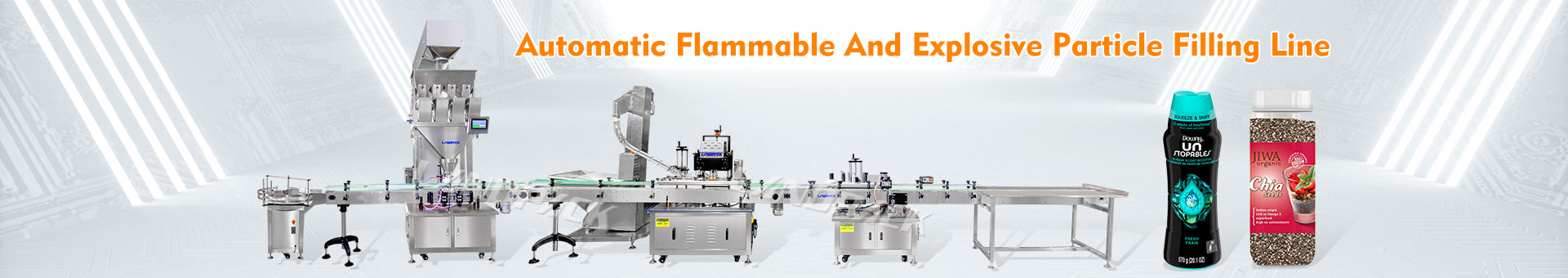

Automatic Flammable And Explosive Particle Filling Line (LFZX-KL-004), it is filling all kinds of flammable and explosive granular and solid products. Each machine is equipped with an explosion-proof electrical box, so as to isolate the ignition source of the electrical appliances and achieve the purpose of explosion-pro.

Packaging Type: cartons, bottles, plastic cans, glass cans, tinplate cans, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

Brief Introduction:

This automatic filling production line is suitable for filling flammable liquids and can be used in an explosive environment. Each machine is equipped with an explosion-proof electrical box separately to isolate the ignition source of the electrical appliances and achieve the purpose of explosion-proof. It is suitable for filling and filling various inflammable and explosive granular and solid materials. It is called linear metering method with high precision. It forms an automated production line with capping machine, aluminum foil sealing machine, and labeling machine. The production line has stable operation, low noise, simple operation, wide adaptability and meets GMP certification requirements.

Parameters:

Model LFZX-KL-004

Filling speed 10-20 Bottles/min

Bottle diameter Φ30mm-Φ135mm (customizable)

Bottle height 40mm-200mm (customizable)

Control system PLC

Total production line power 8.5KW

Power supply 220V、50Hz

Airconsumption 0.6m³/min

Equipment material 304

Description of main packaging process Bottle unscramble-linear scale weighing-filling-lifting upper cover-four-wheel capping-labeling-collection platform

Main applicable functions Suitable for packaging various granular and solid products, such as fish feed, wolfberry, vitamin tablets, calcium tablets, sugar, rice, beans, condiments, washing powder, feed, desiccant, plastic pellets, grains, etc.

Filling containers: PET plastic cans; glass cans; tinplate cans, etc.

Optional supporting devices: unpacking machine; packing machine; carton sealing machine, etc.

Main electrical configuration and brand PLC-Panasonic (Japan); Inverter-Panasonic (Japan); Touch screen-Weilun (China Taiwan); Cylinder-Airtac (China Taiwan)

Feature:

1. This production line adopts automation technology, imported PLC, imported inspection light eye, frequency converter and other electrical appliances, pneumatic components. It has the characteristics of high efficiency, intelligence, wide adaptability, good stability, etc., and is well received by users;

2. This line uses automatic bottle feeding, linear scale filling machine, four-wheel capping machine, wafer positioning round bottle labeling machine, and collection platform to form a fully automated production line;

3. The machine frame of the whole line is made of SUS304 material, with a unique and beautiful appearance;

4. The production line has stable operation, low noise, convenient maintenance, and fully meets the requirements of GMP certification, and is widely used in medicine, food and other industries;

5. Imported PLC and 7-inch touch screen man-machine interface, production parameterized control, simple operation;

6. This kind of production line is relatively advanced, and can be improved according to the different requirements of customers, and can be made into equipment that fully meets the needs of customers.

Get Price & More Detail