Automatic Bag Counting Cartoning Packing System | inline filler

Model: Bag Counting Cartoning Packing System

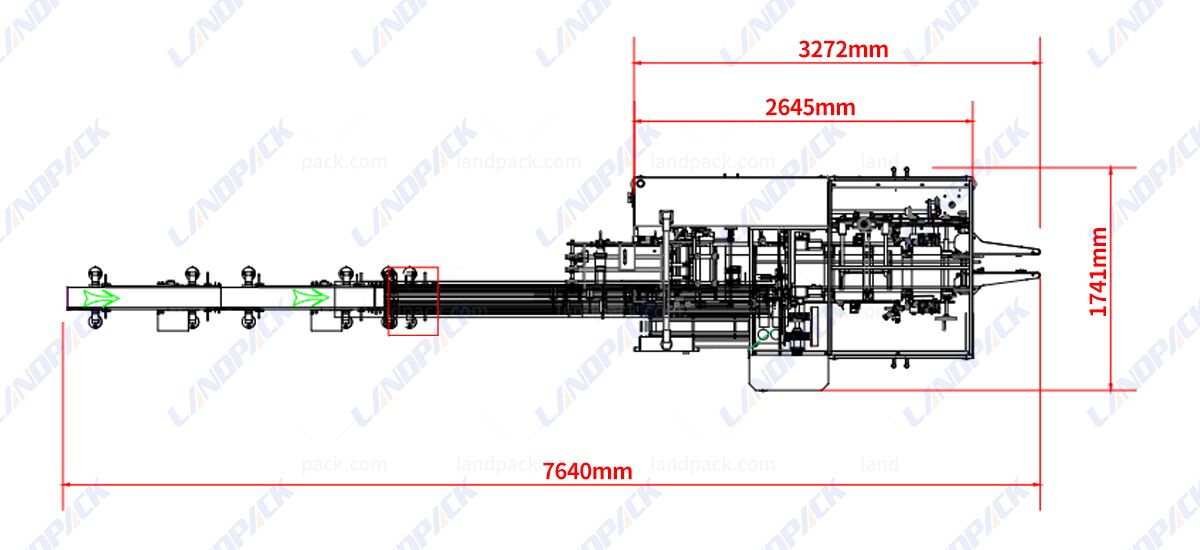

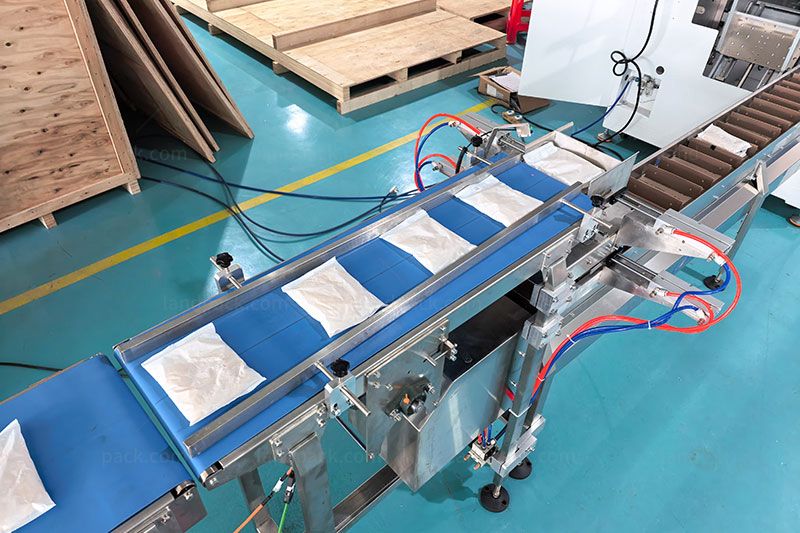

This bagged product cartoning line integrates a transition conveyor, servo positioning conveyor, counting and grouping unit, and full-servo cartoning machine.

Application:

It is designed to automatically transfer finished pouches into cartons with precise counting control. The system ensures stable infeed, accurate product grouping, and reliable carton loading for efficient secondary packaging.

Application:

The streamlined integration reduces manual intervention and helps maintain a steady, predictable line speed. It is widely applicable across food, pharmaceutical, daily chemical, and consumer goods industries, where both counting accuracy and operational efficiency are critical. With a maximum output of up to 60 cartons per minute, the system meets the needs of manufacturers seeking high-efficiency cartoning without losing process control.

Package Type:

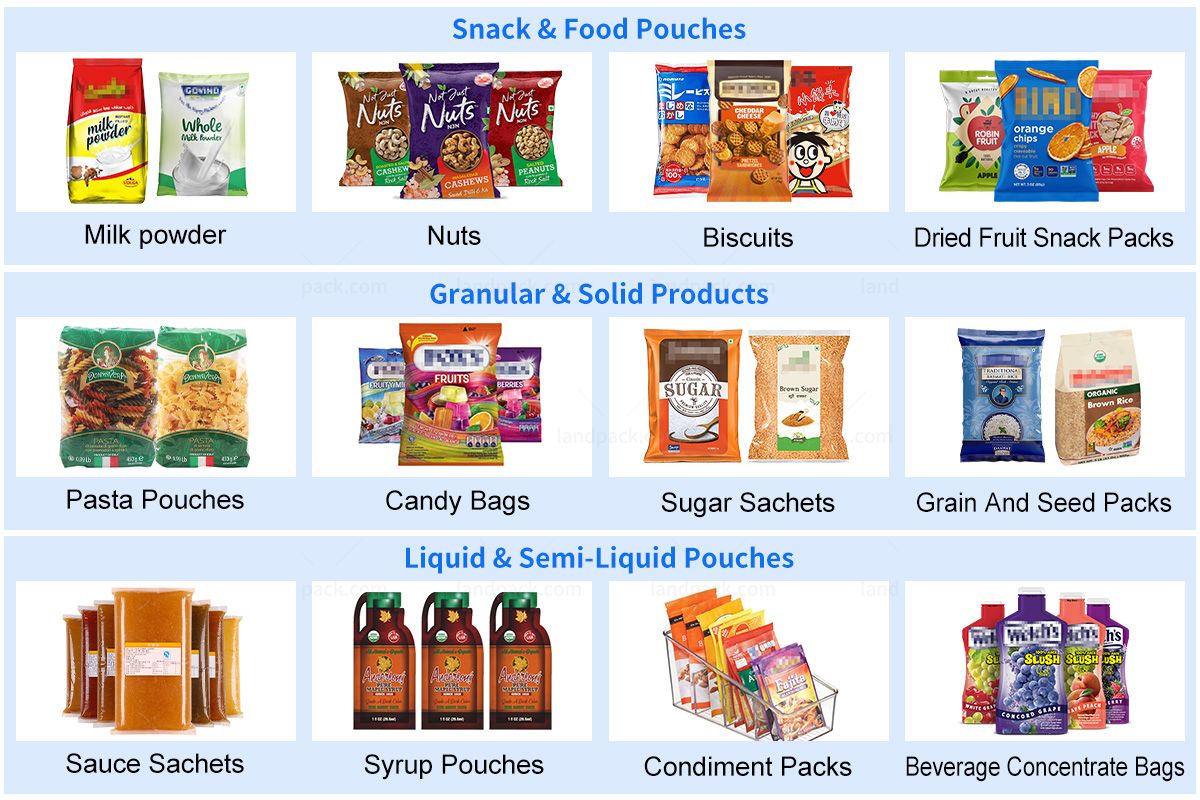

The system is compatible with a variety of flexible packaging formats, including bags, pouches, sachets, stick packs, and pillow packs, supporting versatile automatic counting and cartoning applications.

Suitable Products:

This Packing System is suitable for counting and cartoning a wide range of pouch products with different forms, including solid, granular, liquid, and semi-liquid materials. With stable conveying and accurate counting performance, it ensures efficient and reliable packing for various industries.

Snack & Food Pouches: Milk Powder, Nuts, Biscuits, Dried Fruit Snack Packs

Granular & Solid Products: Pasta Pouches, Candy Bags, Sugar Sachets, Grain and Seed Packs

Liquid & Semi-Liquid Pouches: Sauce Sachets, Syrup Pouches, Condiment Packs, Beverage Concentrate Bags

Workflow:

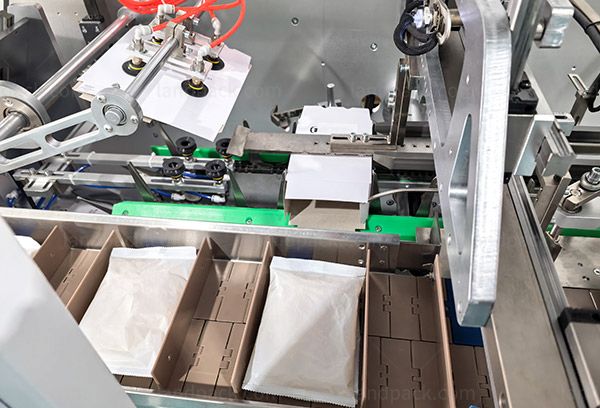

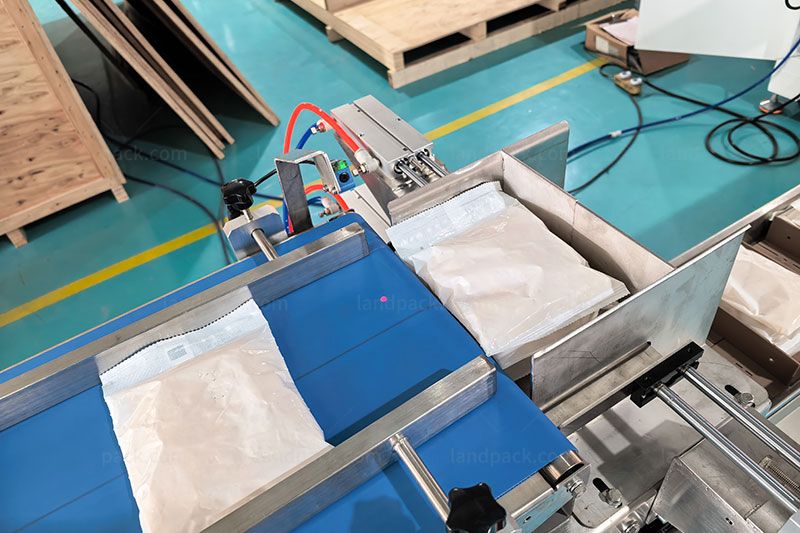

1. Conveying Bag Materials: Bag, pouch, or sachet products are steadily transported through the conveyor system to ensure continuous and orderly feeding.

2. Counting: An automatic counting unit precisely controls quantities prior to cartoning, minimizing errors and reducing manual labor.

3. Pack into Box: The grouped products are then automatically loaded into cartons by the cartoning machine.

4. Box Lid Sealed: Carton flaps are securely sealed, completing the packaging cycle and preparing the boxes for storage or distribution.

| Model | LDDS-80 | LDDS-100 | LDDS-220 |

| Packing Speed | 40-60 boxes/min | 30-50 boxes/min | 30-50 boxes/min |

| Box Size | L: 60-220mm, W: 20-125mm, H: 15-60mm | L: 80-250mm, W: 100-160mm, H: 40-90mm | L: 150-320mm, W: 100-180mm, H: 90-110mm |

| Air Consumption | ≥0.6 mpa, 20 m³/h | ||

| Power Supply | 220V/380V, 50HZ | ||

| Machine Power | 4.5KW | 5.5KW | 6.5KW |

| Machine Size | 3425*1390*1771mm | 3450*1450*1800mm | 4200*1650*1850mm |

| Machine Weight | 1200KG | 1600KG | 2500KG |

Machine Key Components:

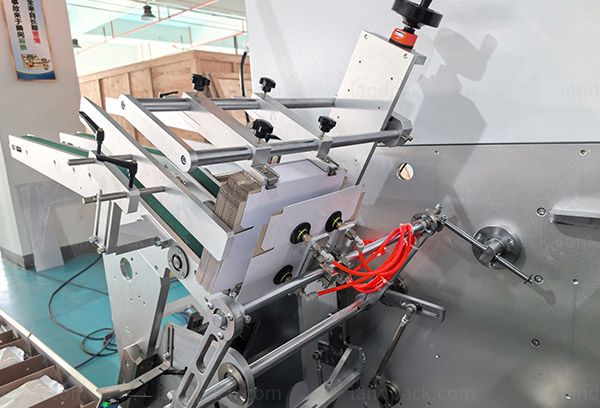

1. Transition Docking Conveyor Belt

2. Servo Counting and Collecting Hopper

3. Collecting and Lifting Conveyor

4. Gift Box Pick up

5. Full Servo Drive Case packer

6. Clamp belt

Feature:

Transition Docking Conveyor Belt Ensures smooth transfer of bagged products between stations, maintaining accurate alignment and uninterrupted feeding across the entire packaging line. |  |

| Servo Counting and Collecting Hopper A high-accuracy, servo-driven counting unit precisely counts and groups bags, guaranteeing consistent quantities prior to cartoning. |

Collecting and Lifting Conveyor Automatically elevates and transports the counted products to the next process step, keeping product flow organized and boosting line efficiency. |  |

| Gift Box Pick Up Accurately picks and positions gift boxes for loading, supporting stable and precise cartoning operations. |

Full Servo Drive Case Packer The fully servo-controlled case packing system delivers fast, accurate, and flexible packing with smooth, dependable performance. |  |

| Clamp Belt A clamp belt mechanism firmly holds cartons in place during packing and sealing, ensuring a clean appearance and reliable finished output. |

Get Price & More Detail