Jam Filling Machine | Automatic Bottles Cans Jars Liquid Filling Machine

Model:

This jam filling machine uses a dual-head piston pump system for accurate volumetric filling of viscous and semi-liquid products. Designed for bottles of various sizes, it delivers stable flow control, clean filling, and repeatable dosing.

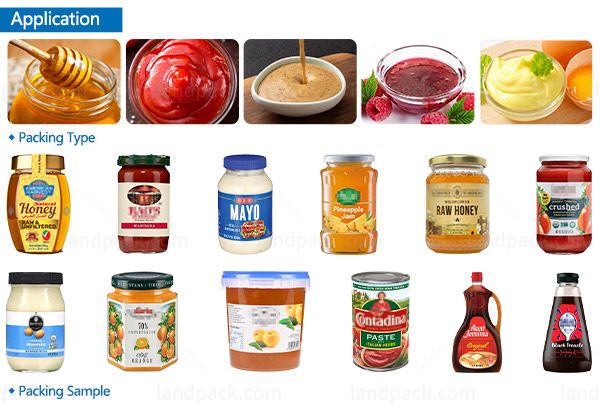

Application:

Typical applications include jam, fruit juice with pulp, honey, shampoo, lotion, liquid soap, cosmetic liquids, sauces, and other similar bottled products.

Application:

The dual-nozzle piston filling machine is applied to bottle filling of thick, sticky, or free-flowing liquids. Its mechanical piston structure ensures precise volume control even for high-viscosity products, while the two filling heads improve efficiency for small to medium production lines. It is commonly used where product consistency and filling accuracy are critical.

Package Type:

This filling machine is compatible with various rigid containers, including plastic and glass bottles, cans, and jars. It supports different shapes and sizes, making it suitable for wide-mouth or standard-neck containers commonly used for food, beverage, cosmetic, and daily chemical products.

Suitable Products:

This machine can be used for a range of viscous to liquid products that are commonly employed in beverage and food packaging. It can handle all kinds of smooth sauces to sweet and sticky spreads to flowing beverages along with edible oils. It's ideal for the continuous, clean filling of different viscosities. This makes it a versatile choice for multiple-product lines.

Sauce Category: Sauce, Coffee Sauce, Honey, Jam

Beverage Category: Juice, Tea Drink, Energy Drink, Plant-based Milk

Condiment & Oil Category: Vinegar, Olive Oil, Sesame Oil, Syrup

Workflow:

1. Bottles/Cans/Jars Feeding: Empty containers are automatically transported to the filling station, providing smooth and reliable feeding for honey jar or bottle filling lines.

2. Liquid Material Filling: The honey filling unit accurately doses high-viscosity product at speeds of up to 40 bottles per minute, delivering clean, drip-free filling performance.

3. Cans Seaming / Bottles Capping: Containers are then securely closed to protect product freshness, with support for both bottle capping and can seaming operations.

4. Labeling (Optional): A labeling system precisely applies brand labels to each container, giving the finished products a clean, professional appearance.

5. Finished Product Output: Finally, the sealed and labeled containers are conveyed to the collection table, efficiently completing the liquid filling process.

| Model | LFZ-01/02/03/04 | LFZ-06 | LFZ-08 | LFZ-10 | LFZ-12 |

| Filling Range | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) |

| Production Speed | <15-25 bottles/min | <20-35 bottles/min | <30-40 bottles/min | <40-50 bottles/min | <60 bottles/min |

| Measurement Accuracy | ±1% | ±1% | ±1% | ±1% | ±1% |

| Power | 2KW | 2.5KW | 3.5KW | 5KW | 5KW |

| Voltage | 220V, 50Hz | 220V, 50Hz | 220V, 50Hz | 220V, 50Hz | 220V, 50Hz |

| Air consumption | 0.6-8Mpa | 0.6-8Mpa | 0.6-8Mpa | 0.6-8Mpa | 0.6-8Mpa |

| Weight | 600kg | 650kg | 800kg | 800kg | 800kg |

| Dimension | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) |

Machine Key Components:

1. Storage Tank

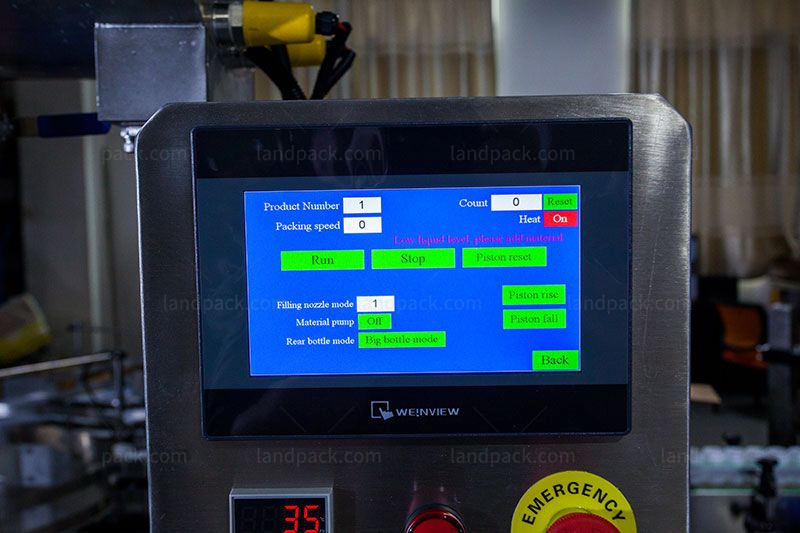

2. Control Panel

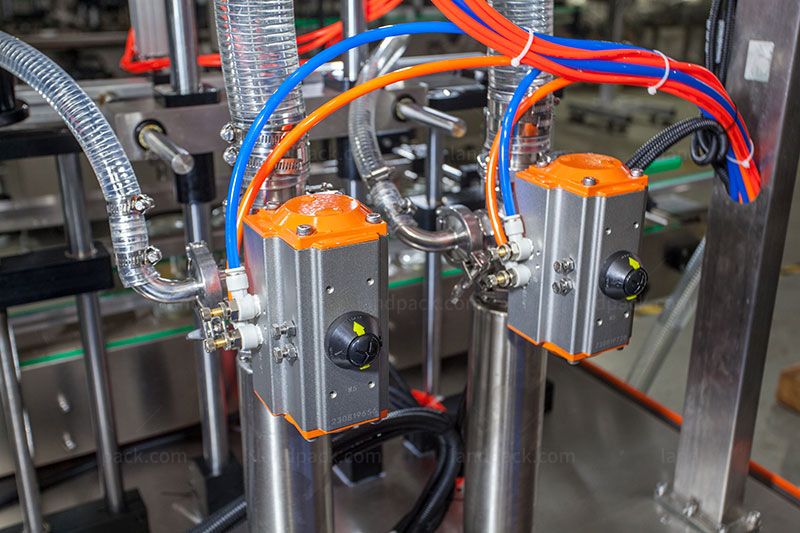

3. Piston Pump

4. Filling Nozzle

5. Conveyor

6. Bottle Stop Device

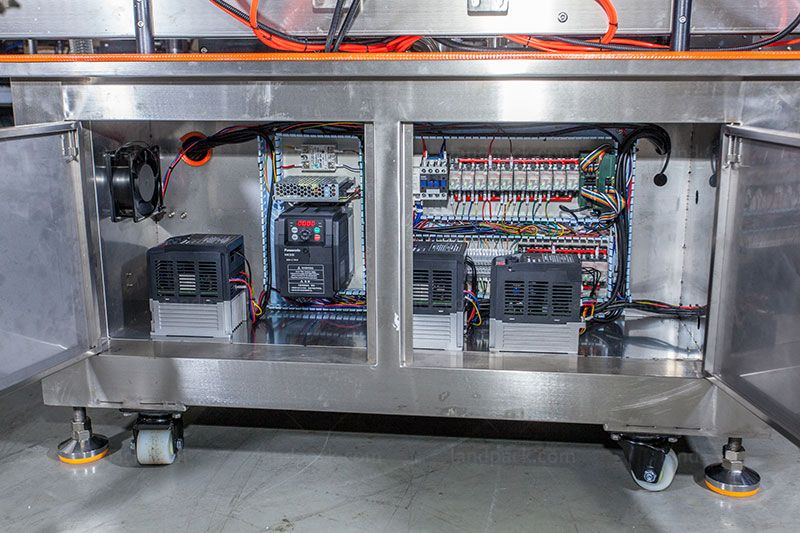

7. Electric box

Feature:

Storage Tank Features a high-volume holding tank that ensures steady honey supply and minimizes the need for frequent refilling, making it ideal for processing high-viscosity materials. |  |

| Control Panel A unified operating panel allows fast adjustment of filling volume and speed, with simple parameter changes to accommodate different bottle, can, or jar sizes. |

Piston Pump Utilizes a high-accuracy piston dosing mechanism designed for thick honey, delivering consistent fill levels with strong suction and pressure control for viscous liquids. |  |

| Filling Nozzle The specially engineered filling outlet minimizes dripping and stringing, ensuring clean, accurate filling into bottles, cans, and jars. |

Conveyor A stable conveying mechanism moves containers smoothly through each processing station, enhancing overall efficiency and reducing the risk of tipping. |  |

| Bottle Stop Device Precisely aligns containers beneath the filling nozzle for sequential, one-by-one filling, preventing misfills and product overflow. |

Electric Box The built-in electrical control enclosure ensures safe and reliable operation, keeps wiring neatly organized, and supports long-term production stability. |  |

Get Price & More Detail