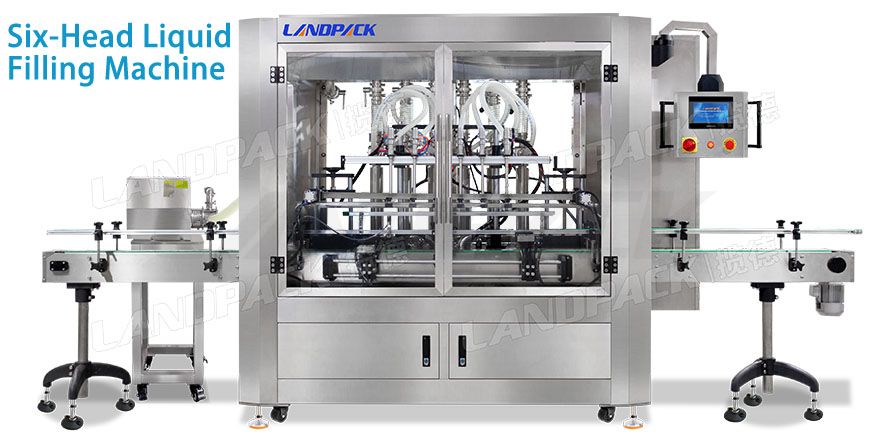

Model: LFH-SC-06

Application:

Suitable for liquid filling with any viscosity, such as medicine, beverage, cosmetics, daily chemicals, detergent and other industries. The bottle type can be flat bottle or round bottle..

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

Description

| Filling Range | 50-1000ml (customizable) |

| Filling Speed | 20-35 Bottle / min (refers to the range of 100-500ml) |

| Control Mode | PLC |

| Power Supply | 220V,50Hz-60Hz |

| Pressure | 0.6-1.0m³/min |

| Power | 8KW |

| Frame Material | 304#Stainless steel |

| Frame material | 316#Stainless steel |

Features

1. The L-type sealing and cutting machine is equipped with an anti miscutting device to protect the safety of products and labor;

2. Imported PLC and 7-inch touch screen man-machine interface are adopted for production parametric control and simple operation;

3. The piston cylinder of the filling machine adopts grinding and anti-wear metering cylinder, with ultra long service life and automatic compensation piston seal;

4. It is suitable for threaded cover, anti-theft and child proof cover, and has more advantages over duck beak cover, pump head cover and nozzle cover;

5. The filling machine adopts special food hose without plasticizer, which is suitable for medicine, food and other industries;

6. The whole machine is made of corrosion-resistant stainless steel, which is convenient for cleaning and disinfection, and meets the national regulations and requirements on food machinery and food hygiene;

7. This line adopts 6-head servo piston filling machine, four-wheel rotating cap, L-shaped sealing and cutting machine, heat shrinkable furnace, collection platform, etc;

8. The production line has stable operation, low noise, convenient maintenance, and fully meets the requirements of GMP certification. It is widely used in medicine, food, cosmetics and other industries;

9. The capping machine adopts the four-wheel clamping principle, which has the advantages of simple and reasonable structure, stable and reliable performance and high working efficiency, and solves the disadvantages of sliding and damaging the cover of the traditional capping machine;

Get Price & More Detail