Automatic Milk Powder Can Filling Seaming Line With UV Sterilizer

Model : LF-PJ-02 / LFP-02

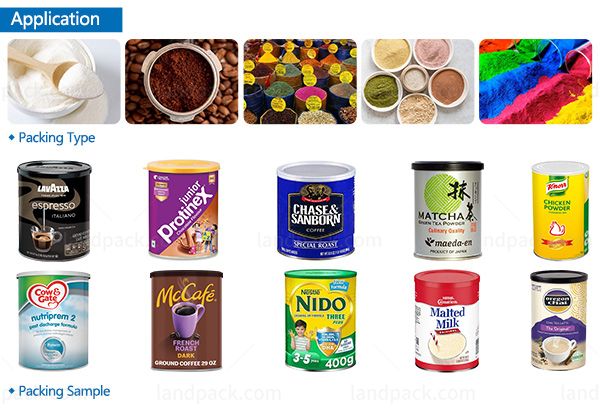

Application :

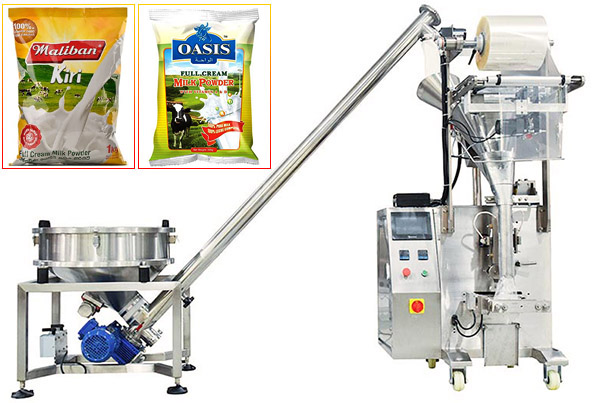

It is ideal for accurately filling and packaging a wide range of powdered products, such as milk powder, protein powder, coffee powder, medicine powder, chemical powder, meal replacement powder, and more.

Application :

It is ideal for accurately filling and packaging a wide range of powdered products, such as milk powder, protein powder, coffee powder, medicine powder, chemical powder, meal replacement powder, and more. This machine ensures high precision, consistent output, and efficient operation across food, pharmaceutical, and chemical industries.

Packaging Type : Cans, Tins, Barrels, Bottles, etc

Kindly Reminder :

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers :

| Model | LF-PJ-02 | LFP-02 |

| Filling Weight | 10-5000g(customizable) | 10-5000g(customizable) |

| Bottle diameter | Φ30-Φ140mm(customizable) | Φ30-Φ140mm(customizable) |

| Bottle height | 50mm-200mm(customizable) | 50mm-200mm(customizable) |

| Yield | 10-20 bottles/min | 20-40 bottles/min |

| Measurement accuracy | ≤500g, ≤±1%, >500g, ≤±0.5% (Varies due to the characteristics of the material) | ≤500g, ≤±1%, >500g, ≤±0.5% (Varies due to the characteristics of the material) |

| Power | 2.5KW | 5KW |

| Silo capacity | 50L | 50L |

| Power Supply | 220V, 50Hz | 220V, 50Hz |

| Working Pressure | 0.6-0.8MPa | 0.6-0.8MPa |

| Weight | 350kg | 550kg |

1. Integrates powder dosing, UV sterilization, nitrogen flushing, and can seaming into one efficient system for high productivity and quality.

2. Uses a servo-driven auger for precise ±1% dosing accuracy, minimizing material waste and overfilling.

3. Features dual-stage UV sterilization to fully sanitize cans and lids before filling, enhancing hygiene and shelf life.

4. High-quality seaming heads create perfect seals without edge damage, preventing leaks and maintaining product integrity.

5. Includes PLC control with touchscreen for easy operation, real-time monitoring, and quick adjustments.

6. All contact surfaces use SUS304/SUS316 stainless steel, meeting CE and dairy-grade hygiene standards.

7. Works with multiple can sizes and powder types like milk powder, protein, baby formula, and supplements.

Optional:

1. Automatic UV cleaning sterilization machine

2. Vibration plate spoons feeder

3. Automatic powder weighing filling machine

4. Automatic vacuum can seaming machine with nitrogen air filling device

5. Laser printer

6. Weight detection and elimination machine

7. Automatic empty cans cleaning machine

8. Automatic plastic lids pressing machine

We have many different kinds of powder customer packing case videos, please feel free to contact us to obtain your product packing case videos.

Get Price & More Detail