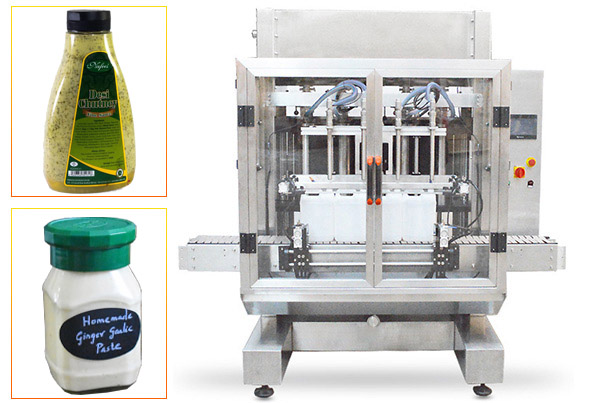

Automatic Paste Filling Capping Machine Line With Self-Cleaning System

Model: LF-YX 6-JS

Application:

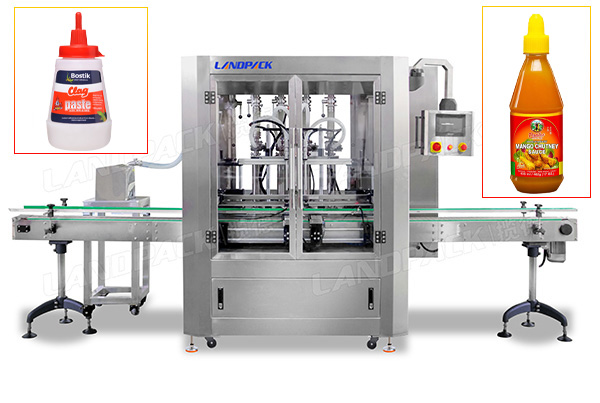

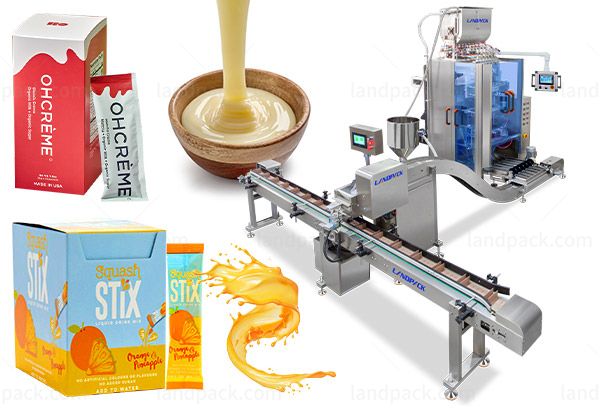

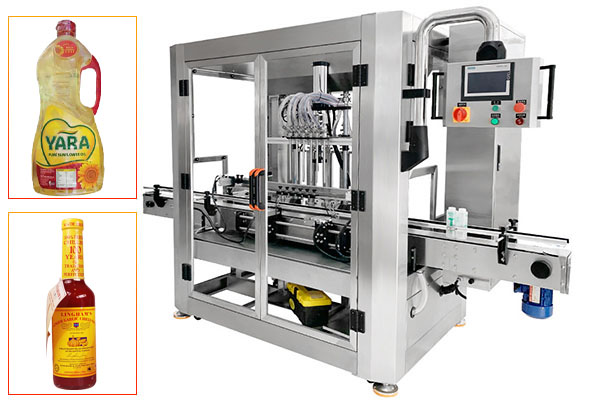

Automatic Paste Filling Capping Machine Line With Self-Cleaning System(LF-YX 6-JS), It is suitable for automatic bottled and canned in paste, ginger garlic paste, sauce, tomato sauce, ketchup, chutney, mayonnaise, tomato paste etc.

Advantages:

1.accurate and reliable filling; 2.independent cylinder quantification system; 3.multi-language human-machine color operation interface easy to set parameters; 4.electric adjustment nozzle height say goodbye to the era of manually adjusting the height of the bottle; 5.electrical components using well-know brands; 6.stable and durable

Application:

Automatic Paste Filling Capping Machine Line With Self-Cleaning System(LF-YX 6-JS), It is suitable for automatic bottled and canned in paste, ginger garlic paste, sauce, tomato sauce, ketchup, chutney, mayonnaise, tomato paste etc.

Packaging Type: It is suitable for various materials, various bottle types, and has a wide range of applications.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples

| Model No. | LF-YX 6-JS |

| Power | 3.0-3.5KW |

| Voltage | AC380V/50Hz |

| Filling scope | 100-500ml 500ml-5L (optional) |

| Speed | 800-1270BPH (for 5L bottle) |

| Precision | ≤±0.5-1%ml(for 5L bottle) |

| Weight | 830KGS |

| Bottle height | 30-350mm |

| Bottle width | Φ10-Φ200mm |

| Dimension | 1700*1300*2100mm |

1. Accurate and reliable filling;

2. Independent cylinder quantification system;

precisely control the speed of the cylinder to realize the precise position movement of the quantitative cylinder.with the siemens programmable controller(plc) and taiwan wen view touchscreen terminal, the filling process is accurate and reliable;

3. Multi-language human-machine color operation interface easy to set parameters;

4. Electric adjustment nozzle height say goodbye to the era of manually adjusting the height of the bottle;

through the precision gear transmission system, with the dc motor, the bottle type is switched by the high and low lifting buttons to make the use easier;

5. Electrical components using well-know brands;

6. Stable and durable;

electrical components using well-known brands, we pay attention to every detail.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail