Tabletop Vial Filling And Capping Machine For Pharma Drug

Model: LD-AFC7C

Tabletop automatic vial and tube filling and capping machines are compact, automated solutions designed to streamline the packaging process for small-scale production runs in a variety of industries.

Application:

Tabletop filling and capping all-in-one machine, with a speed of up to 20-30 bottles/min. Suitable for a variety of pharmaceutical liquids and fluid products such as oral solutions, syrups, vaccines, eye drops, and essential oils. It delivers precision and efficiency, making it an ideal choice for small-batch and pilot production.

What is are automatic vial and tube filling and capping machines?

These versatile machines efficiently and accurately fill vials and tubes with liquid or powder and securely seal them with a cap, minimizing manual labor and increasing productivity. Their small footprint makes them ideal for laboratories, research and development facilities, and boutique manufacturing operations with limited space.

Application:

This vial filling and capping machine is versatile across multiple industries.

* Pharmaceutical Liquids: Oral Solution, Eye Drops, Antibiotic Suspension, Injection Liquid, etc.

* Medical Liquids: Laboratory Reagents, Diagnostic Solutions, Test Kit Buffer, Chemical Reagents, Laboratory Solutions, etc.

* Others: Essential Oil, Toner, Cleaning Agent, Disinfectant, Serum, etc.

Container Type:

Our vial liquid filling machine is designed to handle a wide range of vial types, ensuring flexibility for different industries and applications. It is suitable for Glass Vials, Plastic Vials (PET/PP/HDPE), Crimp-Neck Vials, Screw-Cap Vials, Flat-Bottom & Round-Bottom Vials, Small-Volume Micro Vials, etc.

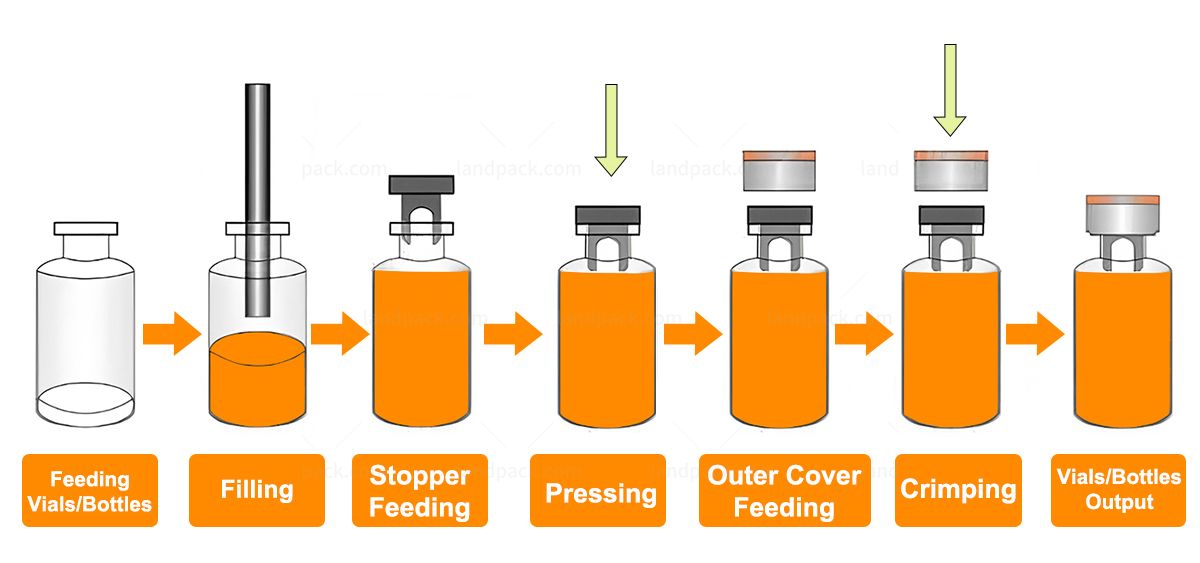

Workflow:

Smart Vial Filling & Capping Process

* Bottle Turntable System

* Peristaltic Pump Filling

* Inner Cap Automatic Feeding

* Stopper Pressing System

* Outer Cap Automatic Feeding

* Cap Calibration Device

* Cap Crimping System

* Finished Bottle Output

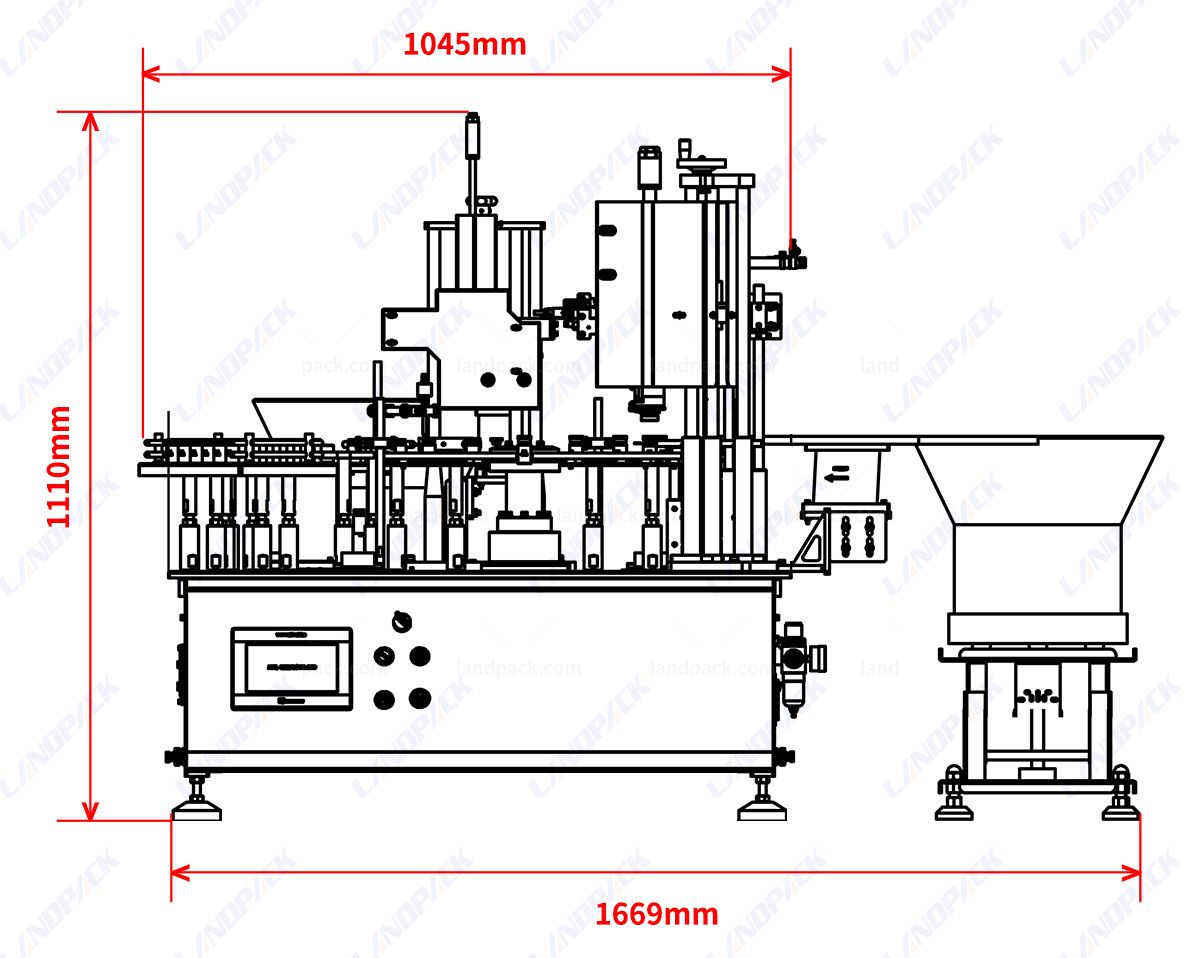

| Machine Model | LD-AFC7C |

| Voltage | 220V/110V, 50-60Hz |

| Power | 500W |

| Filling Pump | Peristaltic Pump |

| Working speed | About 30 bottles/min (depending on bottle size and filling material) |

| Filling Range | 1-10ml (Customizable) |

| Max Flow Rate | 1.5L/min (based on water) |

| Suitable Bottle Size | Can be customized |

| Bottle Cover Size | Can be customized |

| Packaging Size | About 1090*750*960mm(Machine), About 1080*730*580mm(Vibratory Bowls) |

| Packaging Weight | About 157kg(Machine), About 136kg(Vibratory Bowls) |

Machine Key Components:

* Control Interface – Intuitive touchscreen panel for simplified control and parameter adjustment.

* Bottle Handling System – Automatically orients and transfers vials into the machine with consistent precision.

* Liquid Filling Unit – Delivers high-accuracy filling to maintain consistent volume and reduce product loss.

* Stopper Sorting Feeder – Automatically aligns and supplies inner stoppers for uninterrupted workflow.

* Stopper Sealing Mechanism – Applies uniform pressure to insert stoppers firmly, ensuring vial integrity.

* Cap Sorting Feeder – Efficiently orients and delivers outer caps to maintain steady production rhythm.

* Cap Fastening Unit – Crimps outer caps securely, providing a reliable and tamper-resistant seal.

* Product Discharge – Gently outputs finished bottles in an organized manner for subsequent packaging stages.

Feature:

Small-Form Factor Construction: With a space-conscious build, this unit integrates seamlessly into laboratory or cleanroom workflows. |  |

| Intelligent Operational Hub: Navigate system functions with ease through the onboard touch display. The PLC core enables comprehensive, automatic process programming. |

Maximized Yield with Every Fill: The integrated peristaltic pump provides uniform and reliable dispensing, ensuring minimal product waste and greater cost-efficiency. |  |

| Automatic Cap Feeding Vibratory feeders automatically deliver both inner and outer caps. |

One-by-One Cap Sorting Vibration device ensures stable and orderly cap delivery. |  |

| Cap Calibration Device It precisely orients outer caps, leading to cleaner crimps and a lower risk of product damage. |

Get Price & More Detail