High Accuracy Capsule Tablet Bottle Filling Machine Pharma Packaging Line

Model: Pharmaceutical Bottle Packaging Line

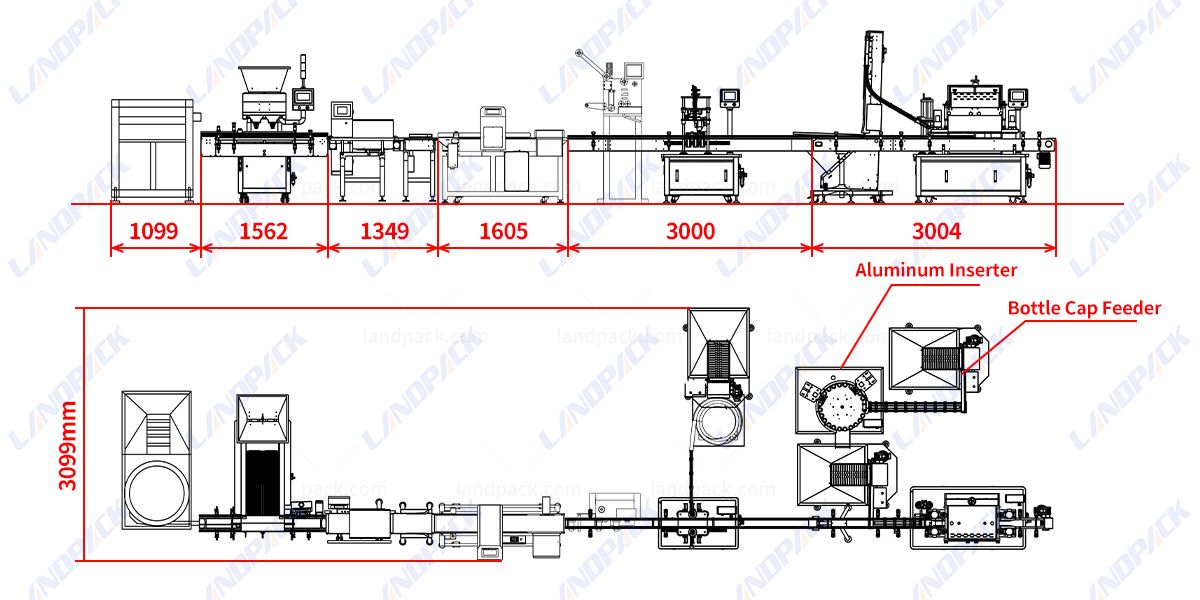

High Accuracy Capsule Tablet Bottle Filling Machine Pharma Packaging Line is designed for precise counting and automatic packaging of capsules, tablets, pills, soft gels, and vitamins.

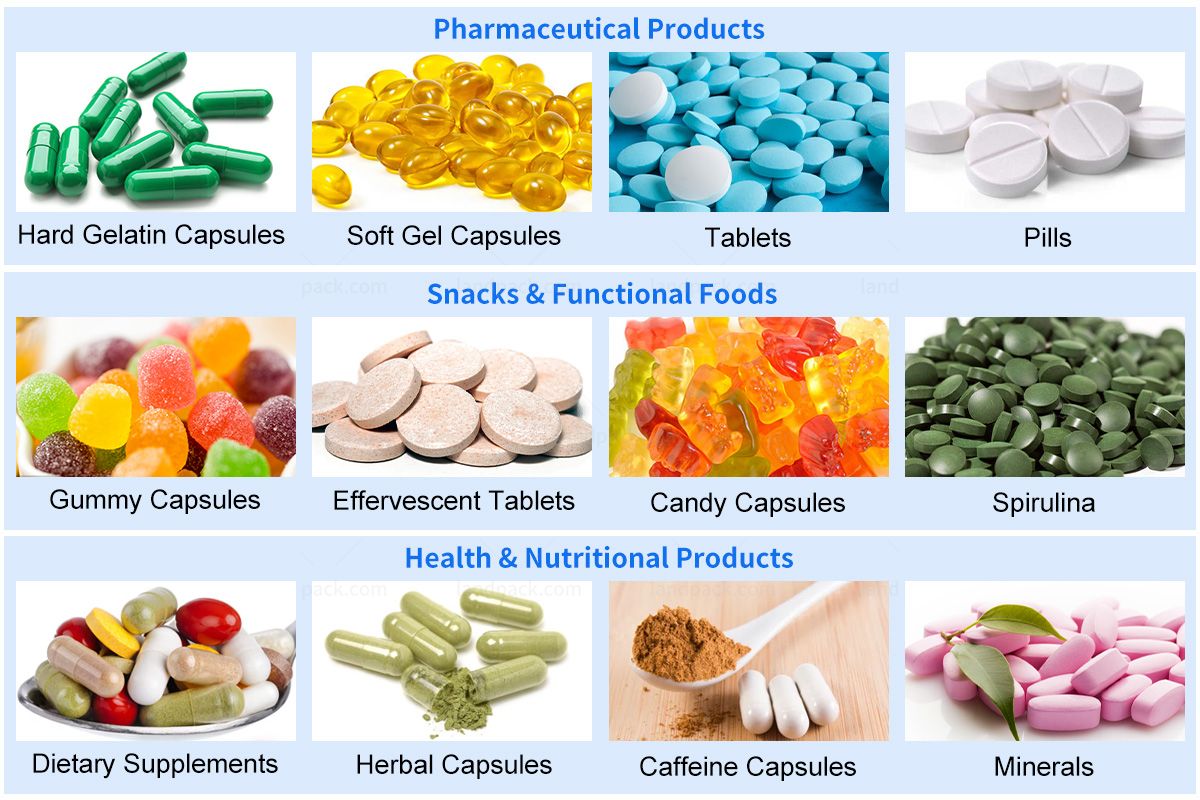

Application:

This pharma packaging line is widely used in pharmaceutical, nutraceutical, and health supplement industries, ensuring hygienic, efficient, and reliable bottle packaging at speeds of up to 40 bottles/min.

What is a Pharmaceutical Bottle Packaging Line?

A Pharmaceutical Filling Line is an integrated, automated system of machinery specifically designed to measure, dispense, and package pharmaceutical products into final containers (such as bottles, vials, blisters, or sachets).

Package Type:

The capsule counting line can be used with a wide variety of bottles and kinds of materials to meet the different needs of production and the market. It's ideal for:

- PET bottles (HDPE PET) are the most commonly used containers for capsules and tablets, which are lightweight, strong durable and water-resistant.

- Glass Bottles are ideal for premium pharmaceutical and nutritional supplements with excellent barrier protection as well in a classy design.

- Amber Bottles are designed to shield items that are sensitive to light, such as herbal capsules soft gels, vitamins and soft gels from UV-induced harm.

- Round Oval, Square, or Round Bottles: Various shapes are available to match the branding and labeling requirements.

Different styles of caps are compatible with flip-top caps, screw caps, caps made from aluminum, and child-safe caps, offering safety and convenience.

Applicable:

1. Pharmaceuticals

Tablets & Caplets: Both coated and uncoated compressed dosage forms, including standard round tablets and oblong caplets.

Hard Capsules: Gelatin or vegetable-based shells containing powdered medications (e.g., antibiotics, pain relievers).

Soft Gels (Soft Capsules): Sealed capsules containing liquid or semi-solid drugs, often requiring the sponge dispenser for settling.

Pellets/Granules: Fine spherical particles used in controlled-release drug formulations.

2. Snack and Functional Foods

Small Candies & Confectionery: Hard candies, jelly beans, chewing gum pieces, and mints that require counting by piece.

Nuts & Seeds: Small packaged portions of almonds, peanuts, sunflower seeds, or mixed nuts.

Dry Grains & Cereals: Specialty ingredients or small-batch cereals, especially those used for topping or small servings.

Functional Food Ingredients: Small, measured doses of ingredients like protein crisps, collagen granules, or fiber supplements designed to be added to other foods.

3. Health & Nutritional Products

Vitamins & Minerals: Standard multivitamin tablets, Vitamin C, Calcium supplements, and mineral capsules.

Herbal Supplements: Encapsulated or pelleted herbal extracts (e.g., Turmeric, Ginseng, Milk Thistle).

Sports Nutrition: Counted doses of amino acid tablets (BCAAs), creatine, or pre-workout granules packaged into bottles.

Dietary Supplements: Items like fish oil soft gels, probiotics, or specialized blends where count accuracy is critical to the label claim.

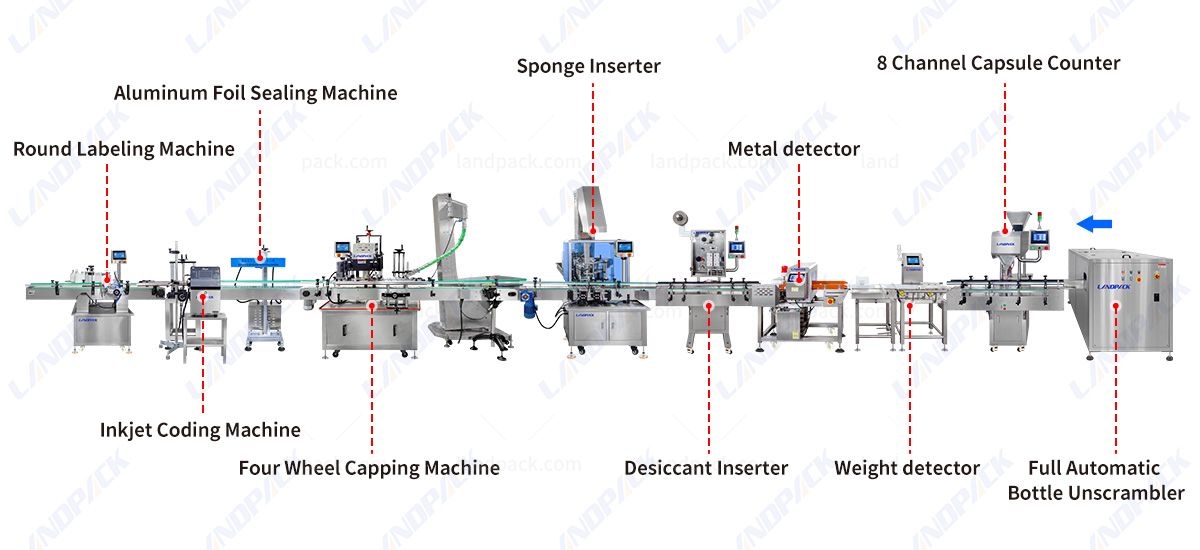

Process Workflow:

This is bottle filling machine pharma packaging line for capsules, tablets, pills. Here's how it works step-by-step:

Bottle Unscrambler: The empty bottles are automatically sorted and aligned to ensure the smooth and uninterrupted flow onto the manufacturing line.

Filling Machine: Capsules or tablets are accurately counted and filled into each bottle with high precision and speed.

Desiccant Filling: A Desiccant packet is automatically added to each bottle to ensure that the contents remain dry and prolong the shelf time.

Sponge Filling: A soft sponge is placed on top of the capsules to prevent damage or movement during transportation.

Cap Feeder: Caps are automatically sorted and oriented, ready for the capping station.

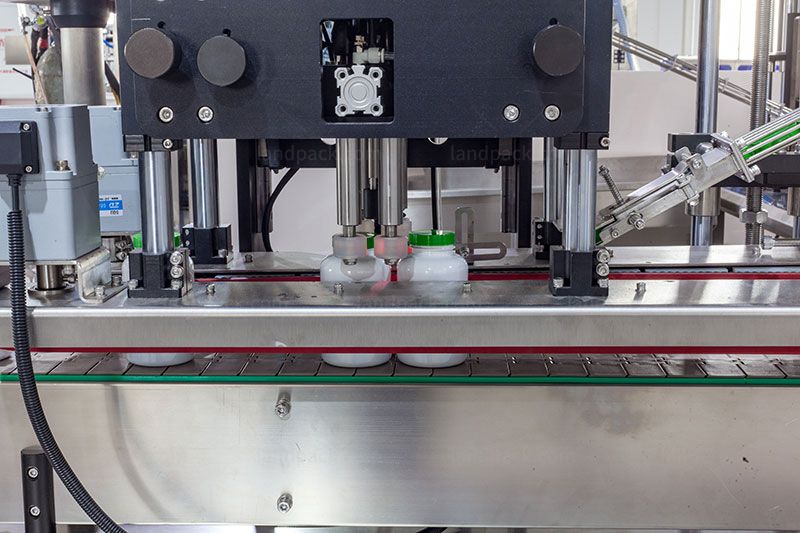

Capping: It can securely tighten each cap, which ensures an airtight seal and constant torque control.

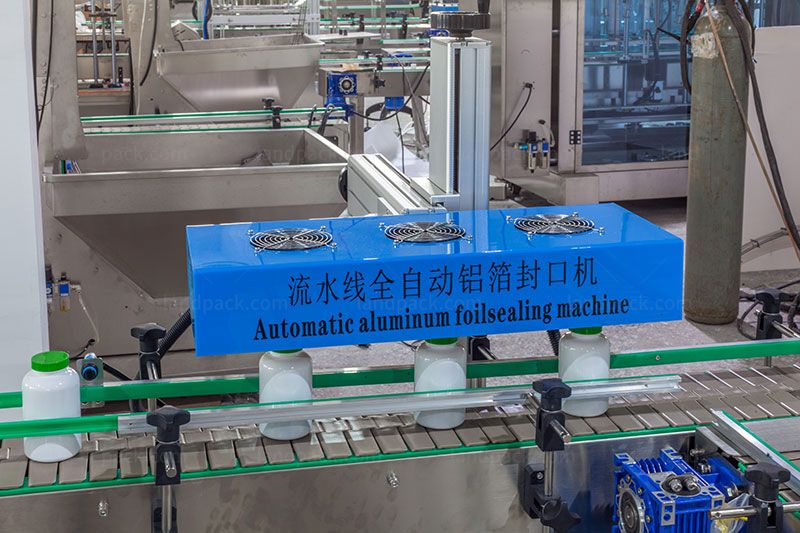

Cap Sealer: An induction sealing device applies a foil seal to avoid contamination and leakage.

Labeling: Finally, labels are applied automatically to bottles to ensure traceability, branding and to ensure compliance.

| Automatic Bottle Unscrambler | ||

| Bottle size range | 15-300 ml | |

| Power | 0.50 KW | |

| Air pressure/supply | 0.5 MPa / 0.2 m³/h | |

| Dimensions (L×W×H) | 1006×1506×1200 mm | |

| Weight | 260 kg | |

| Bottle diameter range | 30-85 mm | |

| Output | up to 260 bottles/min | |

| Power consumption | 3.4 KW | |

| Compressed air | 3.5 cfm (≈ 100 L/min) | |

| 8-Channel Capsule Counting Machine | ||

| Output / Bottles per min | up to 50 bottles/min | |

| Counting Accuracy / Precision | > 99.80 % | |

| Power / Voltage | 0.6 kW, 380 / 220 V, 50 Hz Richpacking | |

| Net Weight | 360 kg | |

| Capacity | 10–30 bottles/min | |

| Counting range | 1–999 grains | |

| Tablet / Capsule size | Tablet: 3–22 mm, Capsule: 00–5 | |

| Air pressure & consumption | 0.4–0.6 MPa, ~120 L/min | |

| Overall size | 1800*1300*1600 mm | |

| Desiccant Bag Dispenser | ||

| Insertion Speed | 60-150 bottles/min (depending on model & sachet size) | |

| Sachet Type | Single strip or continuous roll, paper/film sachets | |

| Sachet Size Range | Length 20-60 mm; Width 15-30 mm (customizable) | |

| Bottle Size Range | Diameter 30-120 mm; Height up to 250 mm | |

| Cutting & Feeding | Automatic sachet cutting, positioning, and inserting | |

| Insertion Accuracy | ≥ 99.8% | |

| Control System | PLC with touch screen operation | |

| Power Supply | AC 220 V, 50/60 Hz, 1.0 kW | |

| Air Requirement | 0.4-0.6 MPa, ~100 L/min | |

| Machine Weight | 300-400 kg | |

| Metal Detector | ||

| Metal detection tunnel size | 200 mm (W) × 150 mm (H) | |

| Continuous weighing range | 6-600 g | |

| Weighing accuracy | ±0.3 g | |

| Max throughput | 120 containers/min | |

| Detection sensitivity (no product) | Fe ≥ 0.8 mm, Non-Fe ≥ 1.0 mm, SS ≥ 1.2 mm | |

| Checkweigher range | 20-5,000 g | |

| Accuracy | ±0.02 g | |

| Max product width/height | up to 290 mm width, 5-280 mm height | |

| Weight detector | ||

| Weighing Range | 1 g - 6,000 g | |

| Accuracy | ±0.2 - ±0.5 g (depending on product & speed) | |

| Max Throughput | 100 - 400 pcs/min | |

| Conveyor Speed | 2 - 60 m/min, adjustable | |

| Conveyor Width | 50 - 600 mm (customizable) | |

| Resolution | 0.01 g / 0.1 g / 0.5 g (optional) | |

| Reject Mechanism | Air blast, pusher, drop gate, or swing arm | |

| Power Supply | AC 220 V, 50/60 Hz | |

| Air Requirement | 0.5 - 0.7 MPa (for reject device) | |

| Machine Dimensions | Approx 1200 × 710 × 750 mm | |

| Sponge dispenser | ||

| Insertion speed | e.g. 100-200 bottles/min | |

| Insertion accuracy | e.g. ±1 mm or better | |

| Bottle neck/mouth diameter range | customizable, e.g. 15–50 mm | |

| Power & pneumatic | e.g. 220 V / 50 Hz, air 0.4–0.6 MPa | |

| Aluminum foil sealing machine | ||

| Model | LD-ZS(Double Heads Aluminum Foil Sealing) | LF-LB-2000(Single Heads Aluminum Foil Sealing) |

| Applicable bottle diameter | Φ10-200mm (Could be customized) | Φ10-200mm (Could be customized) |

| Applicable bottle height | H:40-300mm (Could be customized) | H:40-300mm (Could be customized) |

| Speed | 0-30 bottles/min | 0-10 bottles/min |

| Bottle material | Glass, ceramics, plastics, metals | Glass, ceramics, plastics, metals |

| Voltage | 220V,50HZ | 220V,50HZ |

| Power | 1500W | 1200W |

| Dimension | 1500*800*1750mm | 1200*600*1550mm |

| Bottom Inkjet Coding Machine | ||

| Printing speed | 1024 seconds(5*7) | |

| Power | 220V/50HZ,150VA | |

| Printing direction | Positive sequence/reverse order/reverse/reverse | |

| Printing distance | The nozzle and the object to be sprayed are kept within 3cm | |

| Store information | The system can store 1000 print information | |

| Ink consumption | 70 million words per print | |

| Machine weight | 48kg | |

| Automatic Labeling Machine | ||

| Model | LFT-LG-100(Low speed labeling) | LFT-GS-100(High speed labeling) |

| Label length | 20mm~300mm | 20mm~300mm |

| Label width/height | 20mm~200mm(can be customized) | 20mm~200mm(can be customized) |

| Bottle width | 30-150mm(can be customized) | 30-150mm(can be customized) |

| Roll Label outer diameter | 300mm | 300mm |

| Roll Label inner diameter | 76mm | 76mm |

| Accuracy | ±1mm | ±1mm |

| Label speed | 40-100pcs/min | 60-120pcs/min |

| Conveyor speed | 5~25m/min | 15~20m/min |

| Suitable label type | Adhesive sticker label(transparent label need customized) | Adhesive sticker label(transparent label need customized) |

| Working air pressure | 0.4-0.6Mpa | 0.4-0.6Mpa |

| Voltage | 220V can be customized 4KW | 220V can be customized 4KW |

| Weight | 350KG | 450KG |

| Overall dimension | 3000mm×1450mm×1950mm | 3050mm×1550mm×1950mm |

Machine Key Components:

1. Full Automatic Bottle Unscrambler

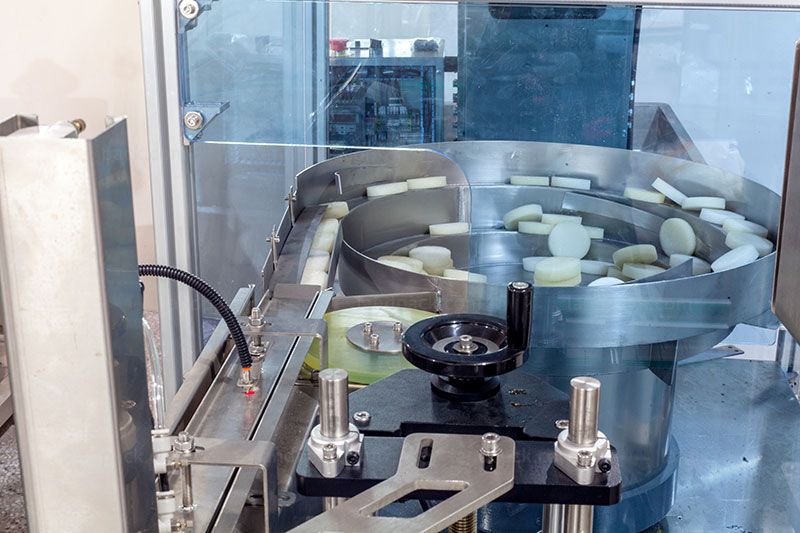

2. 8 Channel Capsule Counter

3. Weight Detector

4. Metal Detector

5. Desiccant Inserter

6. Sponge Inserter

7. Four Wheel Capping Machine

8. Aluminum Foil Sealing Machine

9. Inkjet Coding Machine

10. Round Bottles Labeling Machine

Full Automatic Bottle Unscrambler Automatically organizes and introduces bottles into the line of production in a timely way. It accommodates different sizes and shapes, providing an uninterrupted and reliable operation with no hand-handling. |  |

| 8 Channel Capsule Counter Electronic counting system of high precision with 8 channels that are capable of accurately counting tablets, capsules or soft gels at a high speed. It is equipped with anti-dust and anti-jam technology to ensure stable performance. |

Weight Detector Verifies the weight of the filling on bottles to verify precision and consistency. Any bottles that are overweight or underweight are rejected automatically to ensure that the product is in good condition. |  |

| Metal Detector Effectively removes and detects metal contaminants in bottles, guaranteeing that the product is safe and in line with the pharmaceutical manufacturing standards. |

Desiccant Inserter Automatically inserts bags of desiccant and canisters in bottles, to keep tablets and capsules dry, which extends shelf life while preserving quality. |  |

| Sponge Inserter Put a sponge pad over the top of filled tablets or capsules to stop breaking or damage during transport and sealing. |

Four Wheel Capping Machine Utilizes four-wheel torque control technology to ensure secure and precise cap caps for bottles. Ideal for metal and plastic caps that can be adjusted in tightness and high stability. |  |

| Aluminum Foil Sealing Machine Induction sealing is used to seal the mouth of the bottle with aluminum foil. This provides the protection of leaks and tamper-proofing pharmaceutical products. |

Carton Erector Creates fast-forming cartons to accept pouches, increasing the effectiveness of packaging. |  |

| Round Bottles Labeling Machine Self-adhesive labels are applied smoothly with precision to bottles that are round. Full or half wrap labeling is supported at a rapid speed, and with precise positioning. |

Get Price & More Detail