Protein Powder Filling Machine | Automatic Powder Filling Capping Machine Line

Model: Automatic Powder Filling Line

Built for precise dosing and continuous production, it ensures accurate filling, secure sealing and consistent presentation - ideal for manufacturers requiring reliable performance with a high throughput in powder packaging.

Application:

Its versatile design supports various bottle types and sizes, ensuring accurate dosing, hygienic operation, and professional packaging quality for both commercial and retail markets.

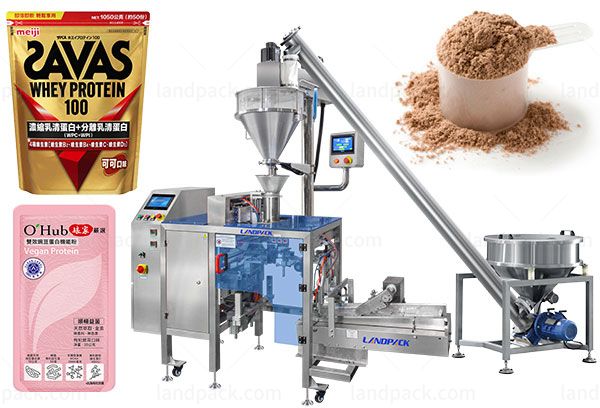

Application:

This line is ideal for packaging a wide range of powder products, including protein powder, milk powder, nutritional supplements, spice powder, functional powders, and other food or health-related powder materials.

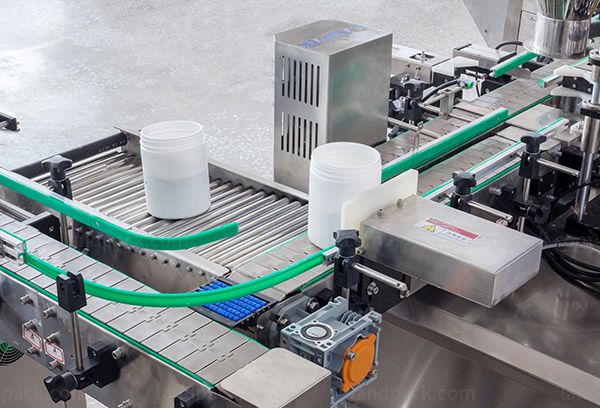

Package Type:

It supports PET and HDPE bottles, wide-mouth jars, and cylindrical or square containers in various sizes. The system ensures stable bottle feeding, clean filling, and secure capping, making it ideal for powdered product packaging.

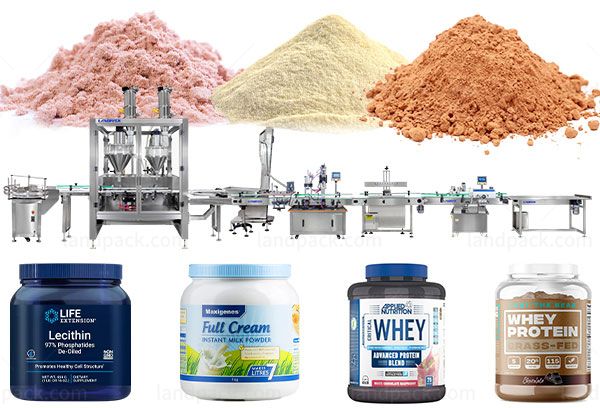

Suitable Products:

This Powder Filling Line is built for accurate, sanitary, and efficient bottling of a broad range of powdered materials.

Nutrition & Sports Powders: Protein powder, meal replacement powder, fitness energy powder.

Health & Supplement Powders: Collagen powder, multivitamin powders, herbal extract powders, dietary fiber mixes.

Food & Ingredient Powders: Milk powder, dairy powder, cocoa powder, matcha blends, spice and seasoning powders.

Workflow:

1. Bottle/Can Infeed – Containers are automatically positioned and conveyed to the filling station for continuous operation.

2. Powder Filling Stage – Each bottle or can is accurately dosed with the required amount of powder, ensuring clean, controlled, and dust-free filling.

3. Capping or Seaming (Optional) – Depending on the container style, the system applies screw caps or performs can seaming to securely seal the product.

4. Labeling Module (Optional) – Labels can be applied for branding, regulatory information, and product identification.

5. Finished Product Discharge – Completed bottles or cans are smoothly transferred to the output area, ready for packing and shipment.

| Powder Filling Machine | |||

| Model | LD-PAF01 | ||

| Filling Range | 10-5000g (Customizable) | ||

| Filling Speed | 20-40 bottles/min | ||

| Measurement accuracy | ±1% | ||

| Power | 5 KW | ||

| Working power supply | 220V, 50Hz | ||

| Working pressure | 0.6-0.8MPa | ||

| Weight | 550kg | ||

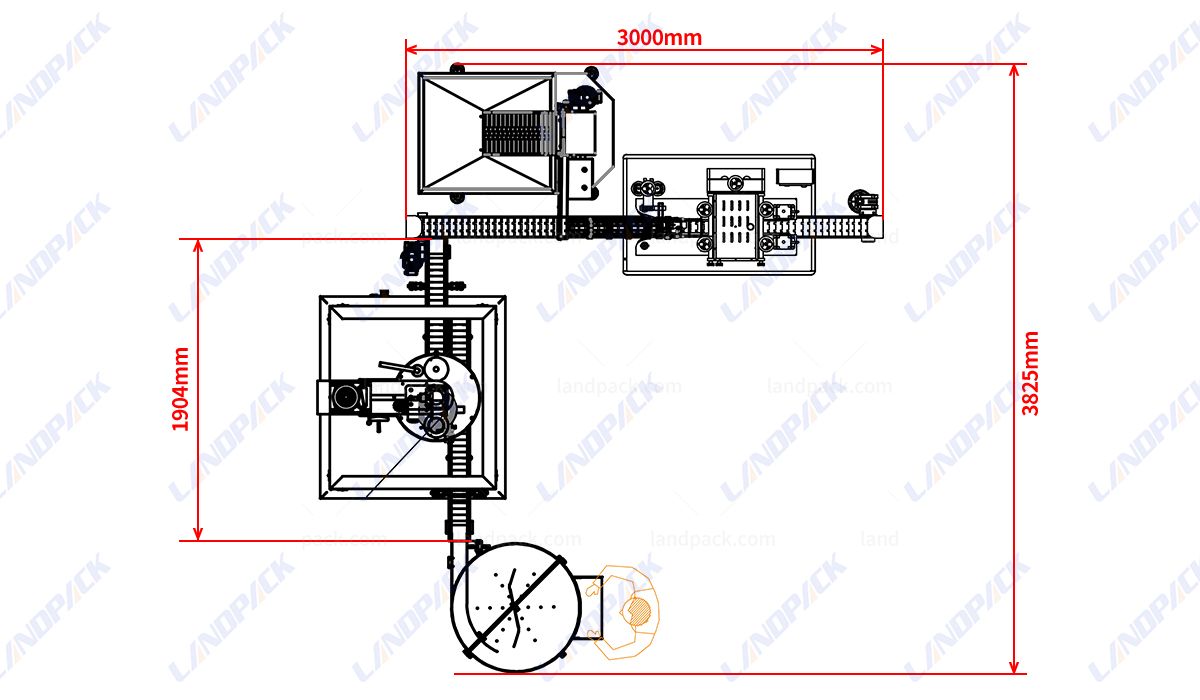

| Size | L2006*W979*H2068(mm) | ||

| Automatic capping machine with cap feeder | |||

| Model | LFX-JX-01 (Four wheel capping) | LFX-GS-150 (Eight wheel capping) | LFX-GS-250 (Six wheel capping) |

| Capacity | 20-50 bottles/min | 40-100 bottles/min | 30-80 bottles/min |

| Bottle cap diameter | Φ22mm-Φ80mm (Could be customised) | Φ18mm-Φ80mm (Could be customised) | Φ18mm-Φ80mm (Could be customised) |

| Bottle diameter | Φ35mm-Φ140mm (Could be customised) | Φ35mm-Φ140mm (Could be customised) | Φ35mm-Φ140mm (Could be customised) |

| Bottle sealing height | 38mm-300mm (Could be customised) | 38mm-300mm (Could be customised) | 38mm-300mm (Could be customised) |

| Power | 1.5KW | 2KW | 1.5KW |

| Voltage | 220V, 50HZ | 220V, 50HZ | 220V, 50HZ |

| Air pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.5-0.7Mpa |

| weight | 250kg | 350kg | 300kg |

| Dimensions | H3000*W800*L1600mm | H3120*W1544*L2122 | H3100*W1244*L2122 |

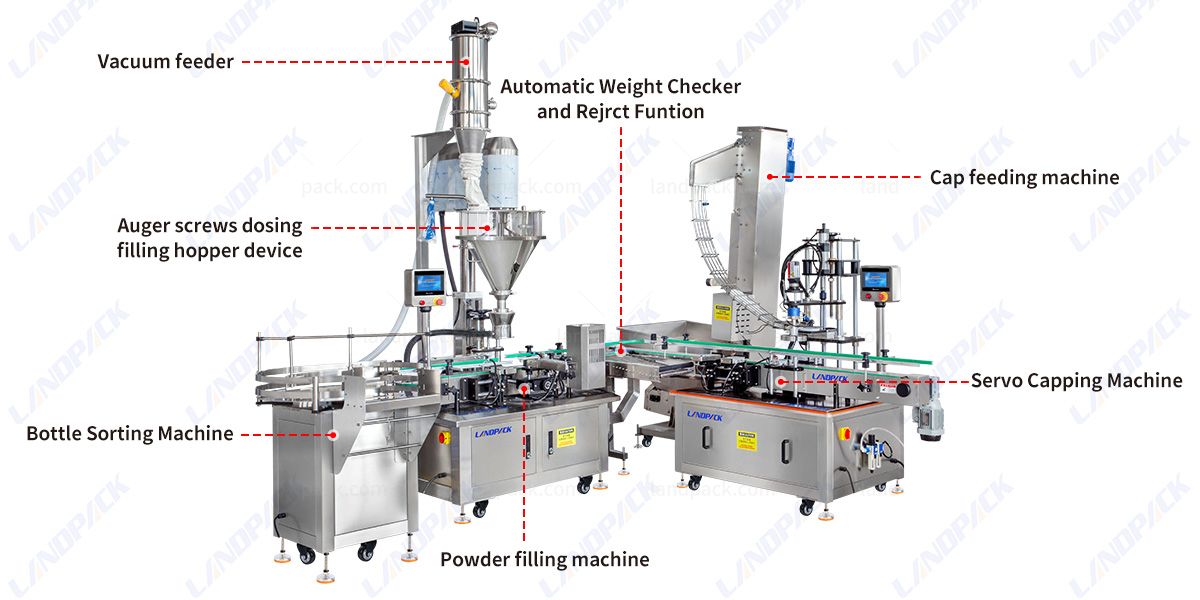

Machine Key Components:

1. Bottle Sorting Machine

2. Vacuum Feeder

3. Auger Screws Dosing Filling Hopper Device

4. Automatic Weight Checker and Rejrct Funtion

5. Powder Filling Machine

6. Cap Feeding Machine

7. Servo Capping Machine

Feature:

Bottle Sorting Machine |  |

| Vacuum Feeder |

Auger Screw Dosing & Hopper System |  |

| Powder Filling Machine |

Automatic Weighing & Reject System |  |

| Cap Feeding & Capping Unit |

Get Price & More Detail