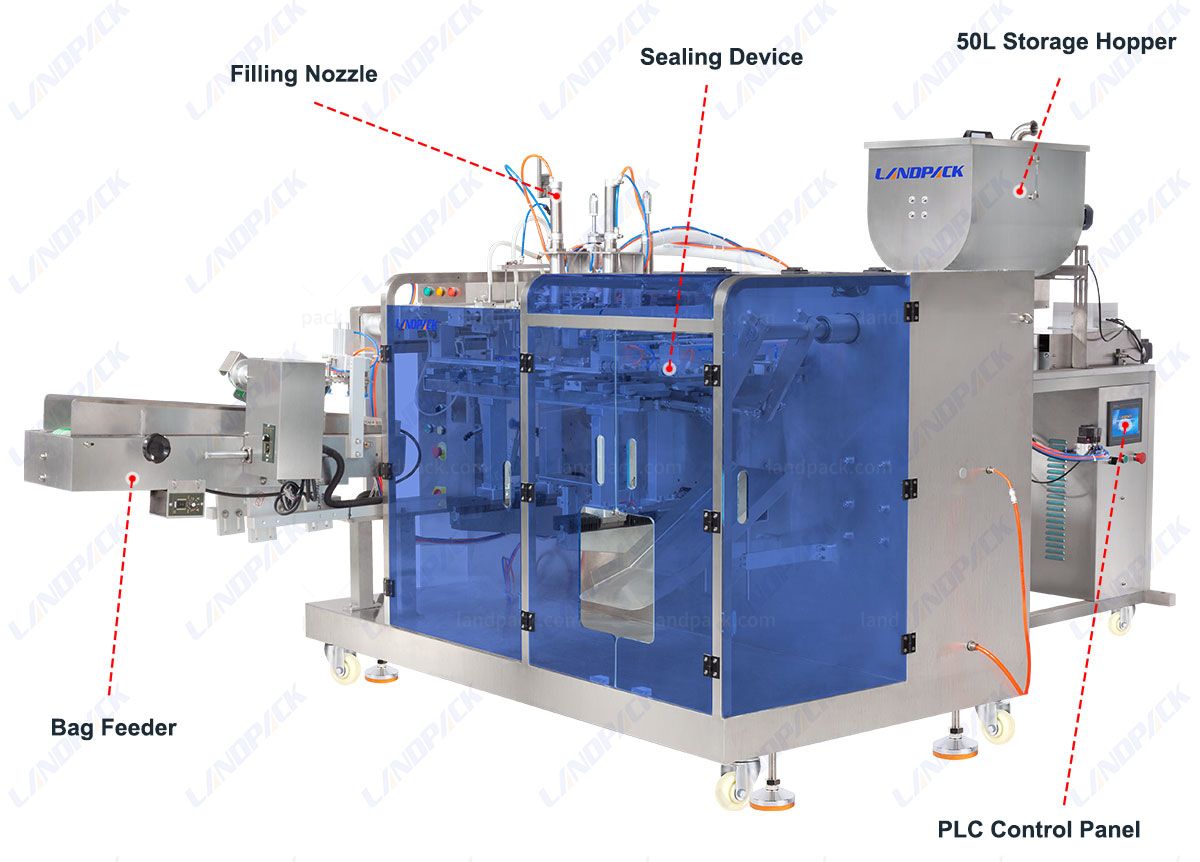

Automatic Sauce Pouch Packing Machine | M Shape & Spout Pouch Filling and Sealing Machine

Model: LDSP-210L

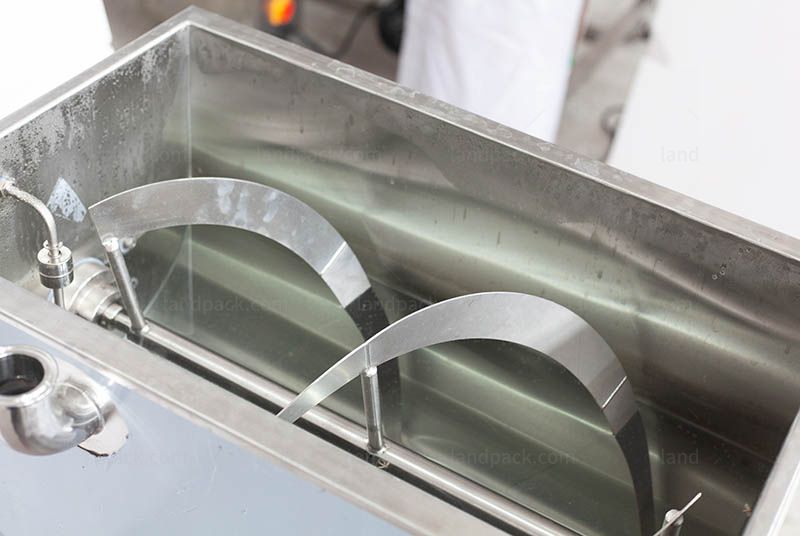

This horizontal pouch packaging line features dual filling nozzles, a spacious 50 L U-shaped hopper, and servo-driven piston pumps for stable, precise liquid dosing.

Application:

Designed for manufacturers of sauces, condiments, personal-care liquids, and household chemicals, this machine reliably fills and seals products like ketchup, salad dressing, shampoo, liquid soap, and liquid detergents.

Application:

Designed for manufacturers of sauces, condiments, personal-care liquids, and household chemicals, this machine reliably fills and seals products like ketchup, salad dressing, shampoo, liquid soap, and liquid detergents. Its dual-nozzle system and large hopper allow efficient handling of both thin liquids and viscous formulas — making it a strong fit for food and daily-use product packaging.

Package Type:

This horizontal premade-pouch packaging system supports a wide range of pouch styles commonly used in food, condiments, daily chemical, and household products. Compatible pouch types include: flat Pouch (3-side seal / 4-side seal), stand-Up Pouch (Doypack), zipper Pouch (resealable pouches), spout Pouch (for liquids, sauces, detergents), gusset Pouch (side gusset or bottom gusset), etc.

Suitable Products:

The horizontal premade pouch packing machine, built with dual filling nozzles and a 50L U-shaped hopper, delivers stable, hygienic, and accurate filling for a wide range of liquid and semi-liquid products. It adapts easily to different viscosity levels and serves multiple industries, including:

Sauces & Condiments: chili sauce, ketchup, soy-based sauces, creamy dressings, flavored pastes.

Liquid & Semi-Liquid Foods: honey blends, fruit jams, dessert fillings, cooking oils, concentrated beverages.

Personal Care & Household Products: shampoo, conditioners, lotions, detergents, cleansing gels.

Workflow:

1. Pouch Feeding: The machine automatically picks and transfers premade pouches from the pouch magazine to the running stations.

2. Date Coding: The printer marks production dates or batch numbers onto the pouch before filling begins.

3. Pouch Opening & Detection: The grippers open the pouch while sensors verify proper opening to ensure safe and accurate filling.

4. Precision Piston Dosing: The piston pump draws and dispenses precise volumes of liquid, handling everything from thin juices to thick sauces.

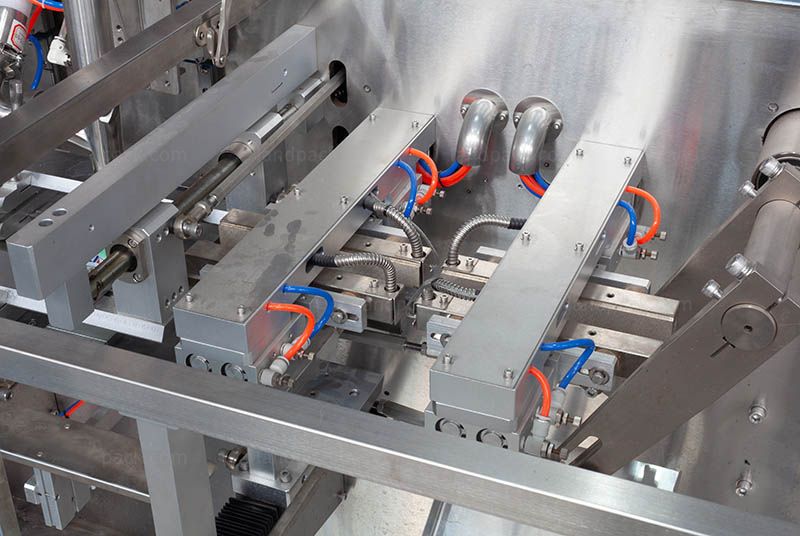

5. Dual-Nozzle Filling: Two servo-controlled filling nozzles inject the liquid or sauce simultaneously.

6. Air-Blow Drip Prevention: A built-in air-blowing function clears residue from the nozzles to prevent dripping and keep pouch mouths clean.

7. Double Heat Sealing: The pouch is sealed twice—primary and secondary sealing

8. Cooling & Discharge: The sealed pouch is cooled and then conveyed to the output belt for collection and packing.

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, Doypack, Box Pouch, Zipper Pouch, Stand Up Pouch, Stand Up Pouch With Hole, Kraft Paper Bag, Side Gusset Bag etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

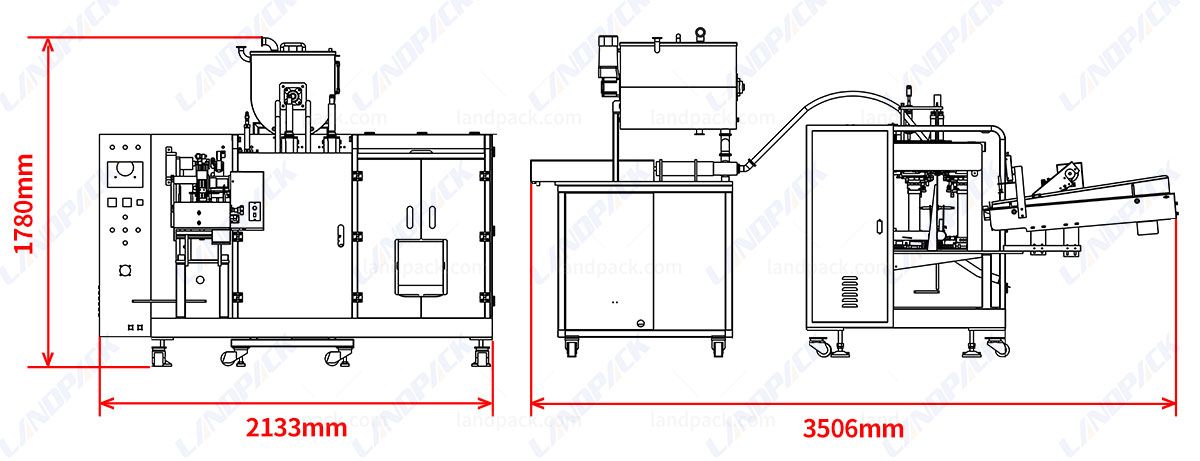

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

| Collocation | Screw metering,screw elevator | |||

Machine Key Components:

1. Filling Nozzle

2. Sealing Device

3. 50L Storage Hopper

4. PLC Control Panel

5. Bag Feeder

Feature:

Dual Filling Nozzles for Simultaneous High-Speed Dispensing Two feeding nozzles are working simultaneously the spout pouch sealing and filling machine drastically reduces the time required to fill, and also increases the efficiency of packing. |  |

| Anti-Drip Air-Blow Function for Clean Filling Each filling nozzle is upgraded with an air blow system, which stops drips from occurring after filling. This ensures that the surface of the pouch is clear and eliminates the waste product and also helps to maintain the hygiene of the pouch. |

Servo-Driven Piston Pump for Accurate & Easy Adjustment The servo-controlled piston system provides precise dosage of volume using Fluid motion control. Users can change the parameters of filling quickly and effectively. |  |

| Double Heat-Sealing Technology for Superior Seal Strength With two stages of heat sealing This machine provides greater strength, more tight and robust pouch seals. |

50L Hopper U-Shaped that has a stable continuous feed The large-capacity U-type container guarantees the continuous flow of viscous and semi-liquid substances. Heating and mixing options provide an even texture and keep the material from settlement. |  |

| Smart Pouch Opening & Safety Detection System The machine will automatically select open, and then examines each pouch that has been made prior to filling, to ensure that the pouch displays perfectly. |

Touchscreen Control for users who have Recipe Memory The PLC touchscreen interface offers users with an easy operation, and simple parameter tuning and multi-recipe memory. |  |

Get Price & More Detail