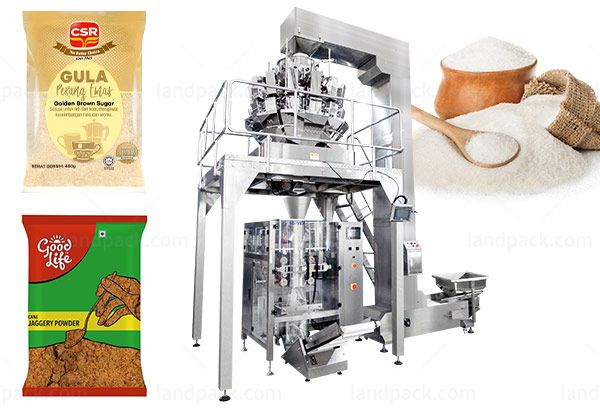

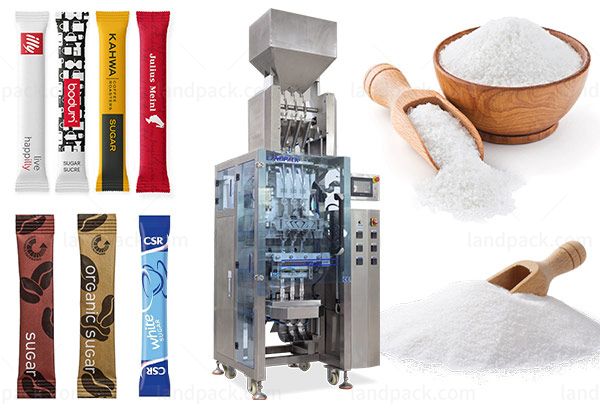

Automatic Sugar Salt Doypack Pouch Packing Machine

Model : LDSP-160A

Application :

Tailored for packaging granular and free-flowing products, such as salt, sugar, rice, nuts, oat, popcorn, candy, chocolate, gummy, pet food, grains.

Advantages :

Similar fine particles into premade doypacks including stand‑up pouches, zipper bags, three‑side or four‑side seal formats.

Application :

Tailored for packaging granular and free-flowing products, such as salt, sugar, rice, nuts, oat, popcorn, candy, chocolate, gummy, pet food, grains.

Suitable Pouch :

Stand‑up pouches, zipper bags, three‑side or four‑side seal formats.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Examples :

| Type | LDSP-160 | LDSP-160Y | LDSP-210 | LDSP-260 |

| Bag Type | 3-side, 4 side sealing bag, Doypack, Box Pouch, Zipper Pouch, Stand Up Pouch, Stand Up Pouch With Hole, Kraft Paper Bag, Side Gusset Bag etc. | |||

| Bag Size | 110-230mm*80-160mm(L*W) | 70-100mm*110-230(L*W) | 100-210mm/110-320mm(L*W) | 100-260mm/110-320mm(L*W) |

| Filling Range | 10g-100g | 10g-100g | 10g-1kg | 10g-3kg |

| Packing Speed | 20-45bags/min(speed is determined by the product filling quantity) | 25-50bags/min(speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) | 20-50bags/min (speed is determined by the product filling quantity) |

| Machine weight | 800KG | 800KG | 900KG | 1000KG |

| Total Power | 2.0KW | 2.0KW | 2.0KW | 2.0KW |

| Work Flow | 1.Giving bag 2. Pick up the bag(coding) 3.Open the bag up and down 4.Filling 5.Heating sealing 6.Output of product | |||

| Dimensions | 1750mm X 1285mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | 2140mm X 1366mm X 1360mm(L*W*H) | |

| Collocation | Screw metering,screw elevator | |||

1. Uses rotor volumetric cup metering for precise portion control, ideal for granular products like salt and sugar—reliable and cost-effective.

2. Features a PLC with touch-screen interface for stable operation, easy adjustments, and quick troubleshooting.

3. Fully automated workflow includes Z-type elevator feeding, vertical bag pickup, ribbon coding, zipper opening, dual sealing, and conveyor discharge.

4. Two-stage heat sealing ensures airtight packaging, perfect for moisture-sensitive products.

5. Made with 304 stainless steel in product contact areas and corrosion-resistant carbon steel frame, meeting GMP and food-grade standards.

6. Includes automatic error detection to stop operation if pouches are missing, unopened, or unsealed—reducing waste and allowing reuse.

7. Modular design supports add-ons like date coding, gas flushing, RFID, perforation, punch holes, or handles for customization.

8. Ensures efficient, high-quality packaging with minimal manual intervention for consistent results.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail