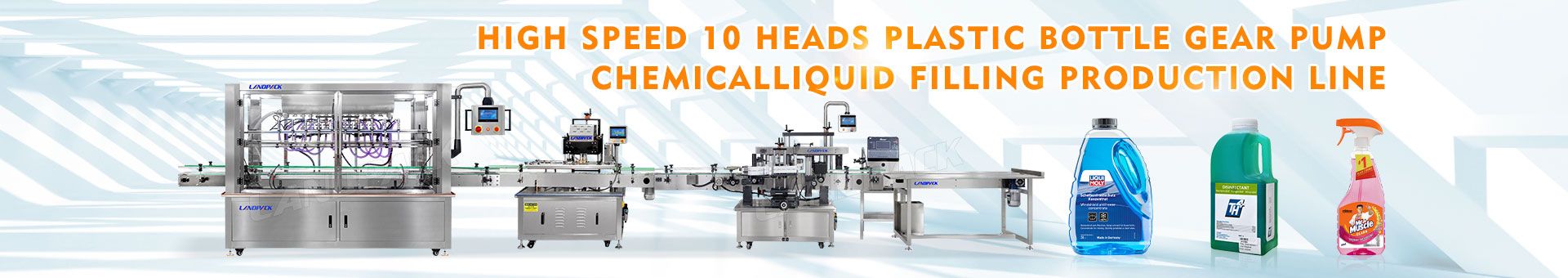

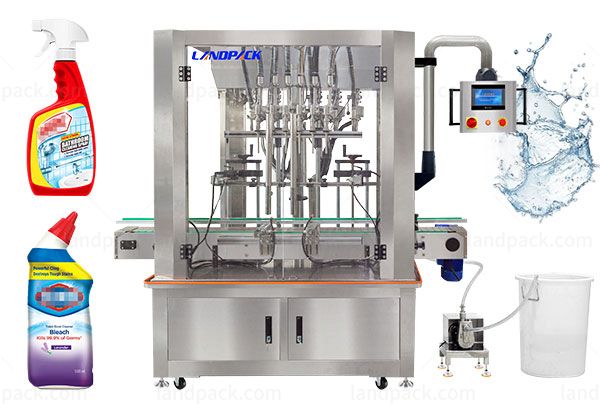

Automatic 4 Heads Gear Pump Chemical Thinner Liquid Bottle Filling Machine

Model: LD-ALF01

Application :

Suitable for all kinds of liquid, such as thinner, chemical liquid, toilet cleaner, gel, liquid detergent, acid, pesticide, alcohol, liquor, bleach, disinfectant, laundry detergent, etc.

Advantages :

The filling machine is equipped with explosion-proof safety features, making it particularly suitable for handling chemical liquids with enhanced operational safety.

Application :

The filling machine is equipped with explosion-proof safety features, making it particularly suitable for handling chemical liquids with enhanced operational safety. Suitable for all kinds of liquid, such as thinner, chemical liquid, toilet cleaner, gel, liquid detergent, acid, pesticide, alcohol, liquor, bleach, disinfectant, laundry detergent, etc.

Kindly Reminder :

Please tell us the following information when you send us an inquiry. Based on your message, we will suggest the optimum solution for reference. Thank you.

1. Your product

2. Filling Range

3. Bottles/cans/jars dimension

4. Bottles/cans/jars material

Packaging Samples :

Machine Model | LFZ-04 | |||

Voltage | 220V 50hz | |||

Filling Head | 4 Heads | |||

Filling Range | 50-1000ml(Customizable) | |||

Filling Speed | 15-25 bottles/min | |||

Filling Accuracy | ±1% | |||

Air Pressure | 0.6-0.8Mpa | |||

Power | 2KW | |||

Machine Material | Stainless Steel | |||

Machine Size | L4000*W1320*H2090(mm) | |||

Machine Weight | 650 kg | |||

1. The gear pump filling system delivers ±0.5% dosing accuracy for precise liquid measurement.

2. Adjustable capacity handles containers from small 100ml bottles up to large 2L jugs with ease.

3. Submerged filling nozzles descend into containers to prevent oxidation and minimize foam formation.

4. Available with explosion-proof electrical components for safe handling of alcohol-based or volatile liquids.

5. Compliant with pharmaceutical, food and industrial standards for diverse application requirements.

6. 10-inch color touchscreen with PLC control enables quick parameter changes and recipe storage.

7. 304/316L stainless steel material contact surfaces meet strict sanitary regulations.

8. Space-saving vertical design features tool-free disassembly for efficient cleaning.

9. Maintains ±1% filling accuracy at speeds up to 60 bottles per minute.

10. Modular construction allows customization for unique bottle shapes and production line integration.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail