Chemical Filling Machine | High Precision Corrosive Liquid Bottle Filling Machine

Model: LFZ-06

This corrosive liquid filling machine is designed for stable, accurate filling of aggressive and standard liquids using corrosion-resistant materials and sealed fluid paths.

Application:

Engineered for manufacturers handling corrosive or reactive liquids, this filling system supports products such as detergents, disinfectants, cleaners, and industrial chemicals.

Application:

Engineered for manufacturers handling corrosive or reactive liquids, this filling system supports products such as detergents, disinfectants, cleaners, and industrial chemicals.

Package Type:

This corrosive liquid filling system accommodates a wide range of container types, including plastic and glass bottles, jars and cans with screw or trigger closures.

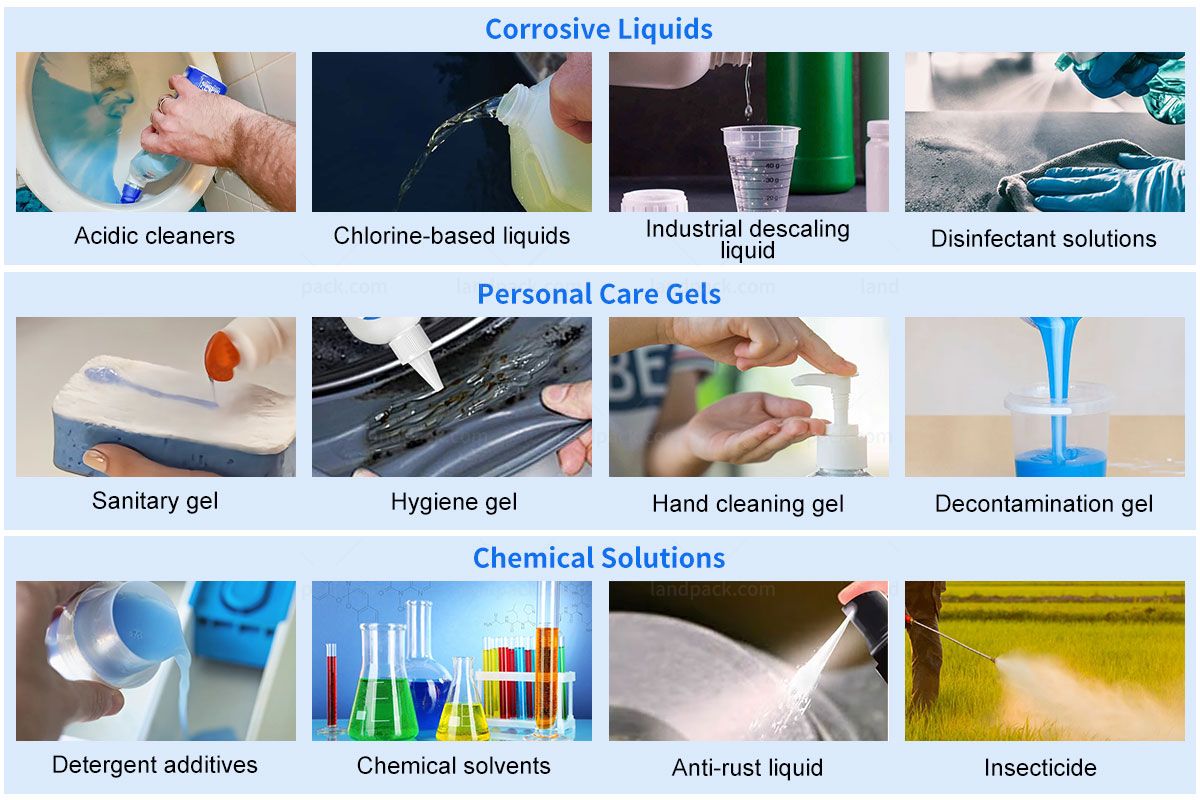

Suitable Products:

This corrosive liquid filling machine is engineered to handle aggressive, viscous, and standard liquid products through corrosion-resistant fluid paths and stable dosing control. It is suitable for a wide spectrum of industrial, chemical, and personal care liquids requiring safe and accurate filling.

Corrosive & Industrial Liquids: Acidic cleaners, chlorine-based liquids, industrial descaling solutions, disinfectants, anti-rust liquids, chemical solvents, detergents, and insecticides.

Personal Care & Hygiene Gels: Sanitary gels, hygiene gels, hand cleaning gels, decontamination gels, liquid soaps, shampoos, lotions, and cosmetic emulsions.

General Liquid & Chemical Solutions: Detergent additives, agricultural sprays, diluted chemicals, functional liquids, and other free-flowing or semi-viscous products compatible with corrosion-resistant filling systems.

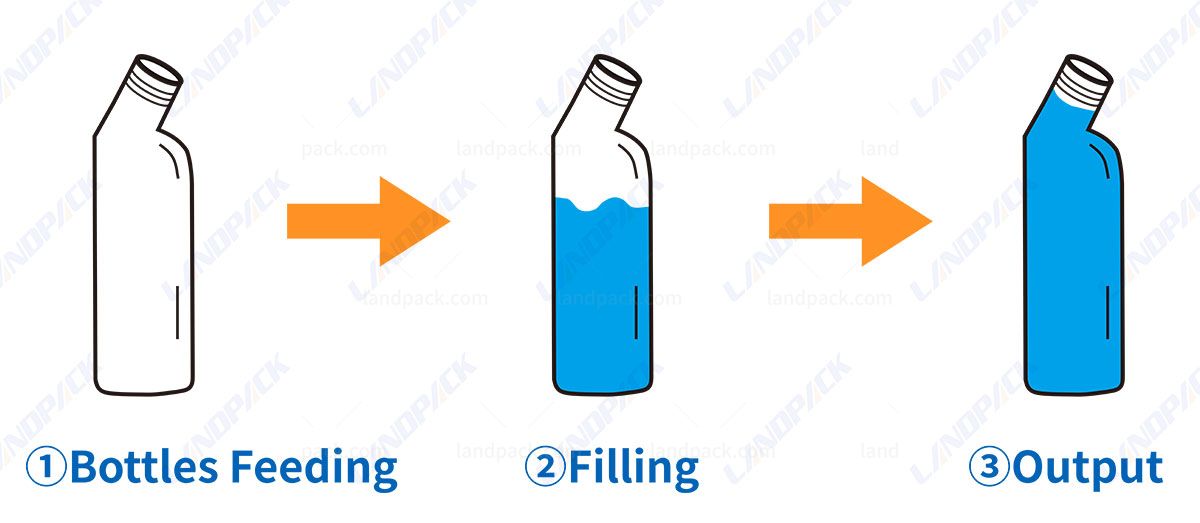

Workflow:

1. Bottles Feeding – Empty containers are automatically arranged and introduced into the production line in a smooth, controlled flow.

2. Filling – The high-accuracy filling unit precisely doses liquid or gel products into each bottle.

3. Output – Once filled, the bottles are gently transferred to the discharge conveyor, prepared for downstream processing or final packaging.

| Model | LFZ-04 | LFZ-06 | LFZ-10 |

| Filing Range | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) |

| Production Speed | 15-50 bottles/min | 20-35 bottles/min | 60 bottles/min |

| Measurement Accuracy | ±1% | ±1% | ±1% |

| Power | 2KW | 2.5KW | 5KW |

| Voltage | 220V, 50Hz | 220V, 50Hz | 220V, 50Hz |

| Air consumption | 0.6-8 Mpa | 0.6-8 Mpa | 0.6-8 Mpa |

| Weight | 600 kg | 650 kg | 1000 kg |

| Dimension | L4000*W1320*H2090 (mm) | L4000*W1320*H2090 (mm) | L4000*W1320*H2090 (mm) |

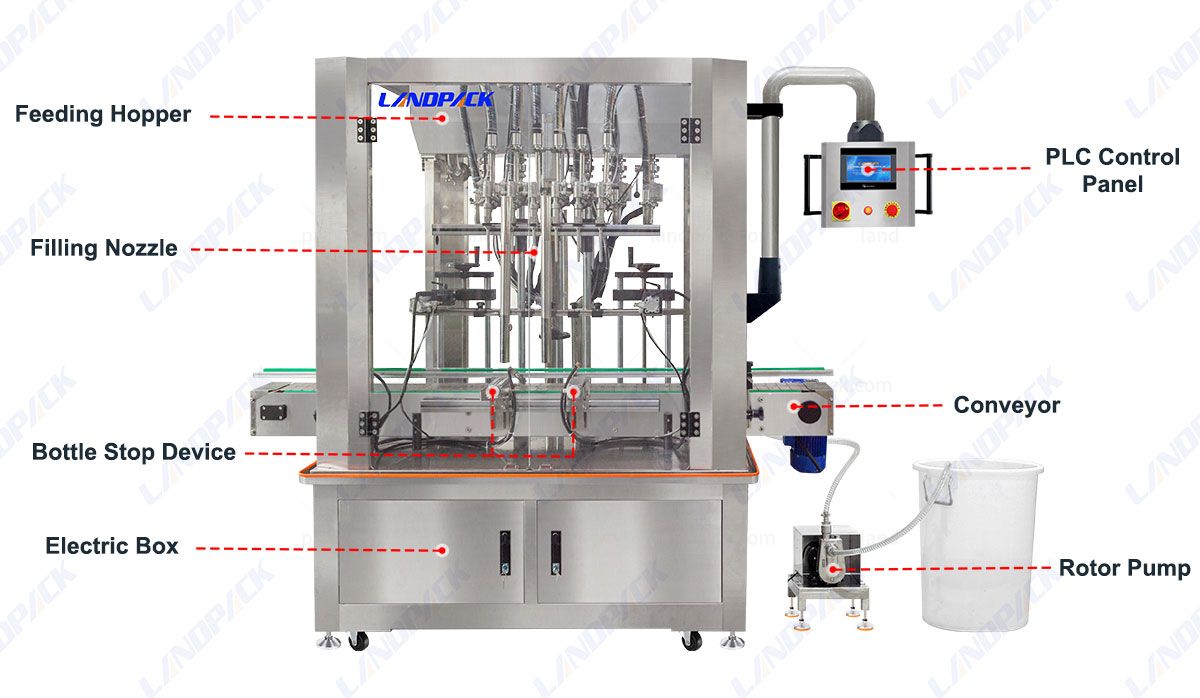

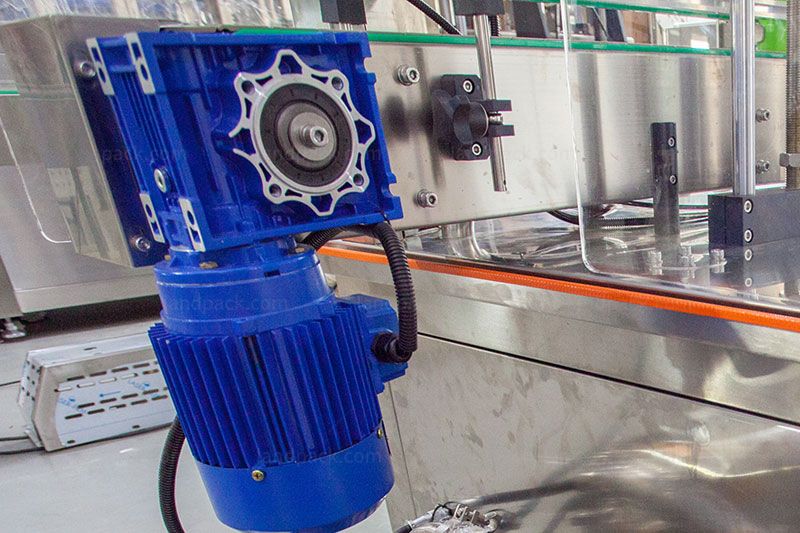

Machine Key Components:

1. PLC Control Panel

2. Conveyor

3. Rotor Pump

4. Feeding Hopper

5. Filling Nozzle

6. Bottle Stop Device

7. Electric Box

Feature:

PLC Control Panel Equipped with an intelligent PLC and a user-friendly touch-screen interface for easy parameter setup, real-time status monitoring, and stable operation. Ensures accurate dosing for corrosive liquids and sanitary gel products. |  |

| Conveyor System Features a chemically resistant conveyor designed for smooth bottle transfer. Consistent, steady movement minimizes spillage risks and supports efficient, uninterrupted production. |

Rotor Pump Utilizes a high-precision rotor pump engineered for viscous and corrosive media. Delivers accurate, smooth filling performance while offering excellent chemical resistance and long service life. |  |

| Feeding Hopper Large-volume hopper constructed from corrosion-resistant materials provides a stable and continuous product supply, enabling nonstop filling operations. |

Filling Nozzle Precision filling nozzles with anti-drip design prevent splashing and leakage. Well suited for acidic liquids, gels, and hygienic chemical products. |  |

| Bottle Stop Device Automatic bottle stopping and alignment system ensures correct positioning during filling, improving accuracy and reducing the risk of tipping or misfills. |

Electric Box Fully sealed electrical cabinet with corrosion-resistant protection ensures safe operation, reliable control performance, and easy maintenance in demanding chemical processing environments. |  |

Get Price & More Detail