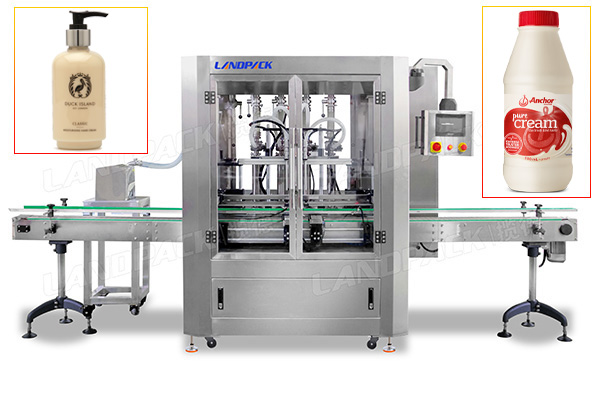

Automatic Cream Bottle Filling and Capping Line

Model: LF-YX 6-JS

Application:

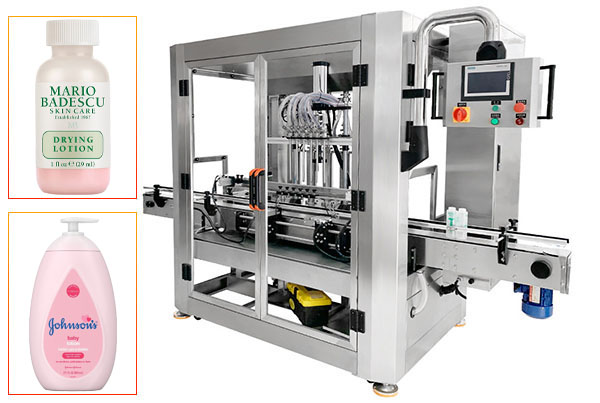

This series of filling machines are designed specially for filling cream and sauce products such as cosmetic cream, honey, tomato sauce etc.

Compatible with 5 types of bottles, , no need to change accessories, various round bottles, square bottles, octagonal/ special-shaped bottles, hexagon bottles, etc;

Application:

This series of filling machines are designed specially for filling cream and sauce products such as cosmetic cream, honey, tomato sauce etc.

Compatible with 5 types of bottles, , no need to change accessories, various round bottles, square bottles, octagonal/ special-shaped bottles, hexagon bottles, etc;

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

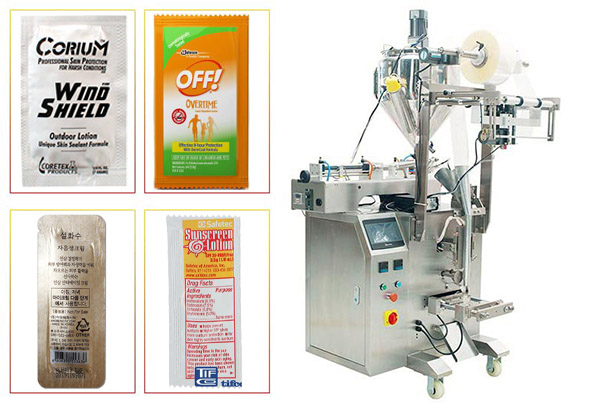

Packaging Samples

| ITEM | single head | 4-6 heads | 8-10 heads | 12 heads |

| Fiilng speed | 800BPH | 1500-2500BPH | 2500-3500BPH | 4000BPH |

| Accuracy | ±2g (200g/bottle) | |||

| Voltage | 380\220V(customizable)50Hz | |||

| Air pressure | 0.6-0.8Mpa | |||

| Hopper capacity | 90kgs | 120kgs | 180kgs | 260kgs |

| Dimension(L*W*H)mm | 800*1500*1600 | 1600*1600*2200 | 2200*1800*2200 | 2300*1800*2300 |

| Weight | 423kgs | 1156kgs | 1291kgs | 1635kgs |

Compatible with 5 types of bottles, , no need to change accessories, various round bottles, square bottles, octagonal/ special-shaped bottles, hexagon bottles, etc;

100-500g, 500-2500g, 1-5kg, three conventional capacities. Meet the requirement of 90%of the quantitative filling of sauce, and the special capacity can be customized;

Quantitative error IS 2G, 50% higher than the standaed;

Can be filled with large particles of 20mm, a variety of different sauces can be filled;

Automatic feeding + stirring + quantitative filling + heating and heat preservation.

FOOD GRADE STAINLESS STEEL:

The whole machine is made of food grade SUS 304/316L stainless steel, which is safe and sanitary, and meets the requirements of food production.

IT CAN WITHSTAND 120 DEGREES:

The material conveying pipeline is made of silica gel, which is resistant to high temperature of 120℃and does not contain plastic agent, and does not decompose at high temperature.

LOWNOISE:

The servomotor is used to drive the piston for quantification. There is no consumable material in 12000-hour operation, and the noise is lower than 40 decibel. Equipped with self-cleaning system.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail