High Speed Ketchup Sachet Multilane Packing Machine

Model: LDFS-480L

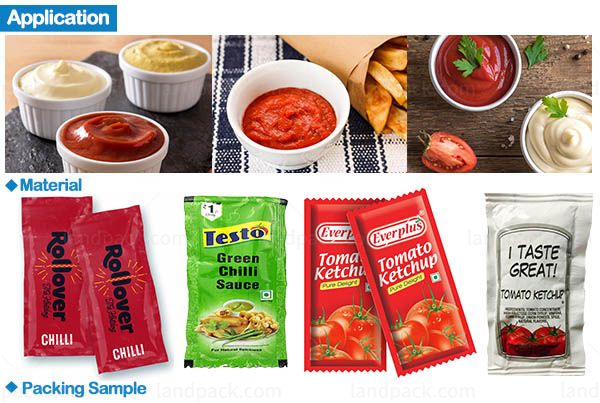

Application:

High speed ketchup sachet multilane packing machine, it suitable for viscous liquid packaging, such as ketchup, chili sauce, honey, pizza sauce, peanut butter, tartar sauce, chocolate sauce, cream, shampoo etc.

Advantages:

This machine is applicable for dosing liquid or semi-liquid and sealing in form of 3/ 4 side sealed sachet.

Application:

High speed ketchup sachet multilane packing machine, it is suitable for filling liquids and sauce of any fluidity in various industries.

Examples:

Ketchup, syrup, peanut butter, chocolate sauce, juice, shampoo, pizza sauce honey, jam, paste, oil, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

Model | LDFS-480L | LDFS-720L | LDFS-960L |

| Track Number | 4~6 Track | 4~10 Track | 4~12 Track |

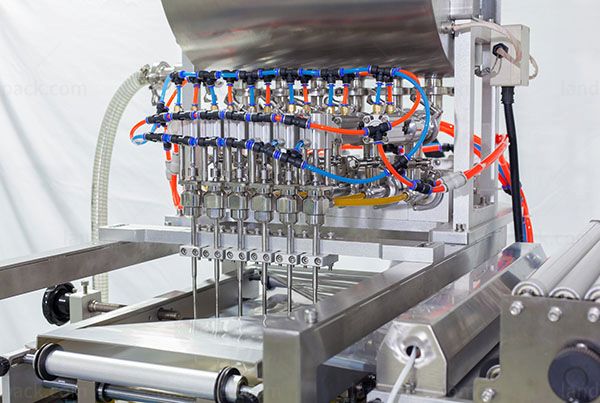

| Filling Method | 1.Piston pump; 2.Peristaltic Pump | ||

| Capacity | Max.40 cycle/min | ||

| Sachet Size | L:45--120mm; W:35-60mm | L:45--120mm; W:35-90mm | L:45--120mm; W:35-120mm |

| Film Width & Thickness | Max.480mm;0.07-0.1mm | Max.720mm;0.07-0.1mm | Max.960mm;0.07-0.1mm |

| Sealing Type | 3/4 sides sealing | 3/4 sides sealing | 3/4 sides sealing |

| Cutting Type | 1. Straight Cutting; 2. Zig Zag Cutting; 3. Continuous Cutting | ||

| Air & Power | 0.8 mpa 0.8m³/min; 2.8kw | 0.8 mpa 0.8m³/min; 4.1kw | 0.8 mpa 0.8m³/min; 5.5kw |

| DIM & WT | 950*1470*1750mm; 300kg | 1153*1654*1750mm; 400kg | 1415*1686*2130mm; 500kg |

1. Automatically complete all tasks such as measurement, bag making, filling, sealing, batch number printing, cutting and counting.

2.Stainless steel contact part and the machine outer shell, high feature for liquid running environment.

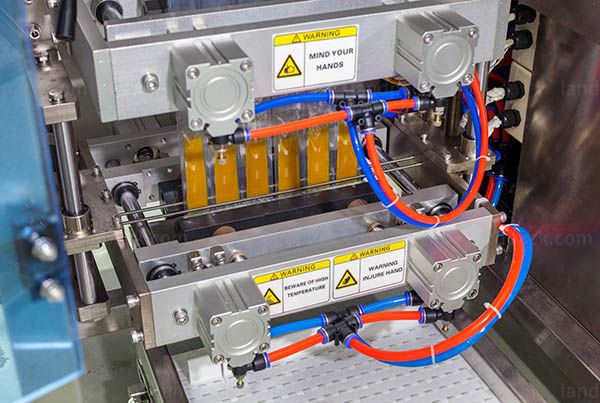

3. Automatic slitting film system, multi-line row and bag sealing at the same time.

4. Servo film running system, pneumatic control for horizontal sealing, accurate positioning, remarkable performance and beautiful packaging.

5.The dual light source photoelectric detection system is stable and reliable to ensure the integrity of the packaging bag.

6. Intelligent PLC control system, stable operation of the machine, convenient and fast operation,

7.A variety of automatic alarm protection functions can effectively reduce the loss of materials and ensure work safety.

8. High precision photocell sensor for auto tracking the eye mark printing on the film roll, so cut each bag at precisely position.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail