Mayonnaise Rotary Spout Pouch Filling Machine | Premade Pouch Doypack Pouch Packing Machine

Model: LD-8230

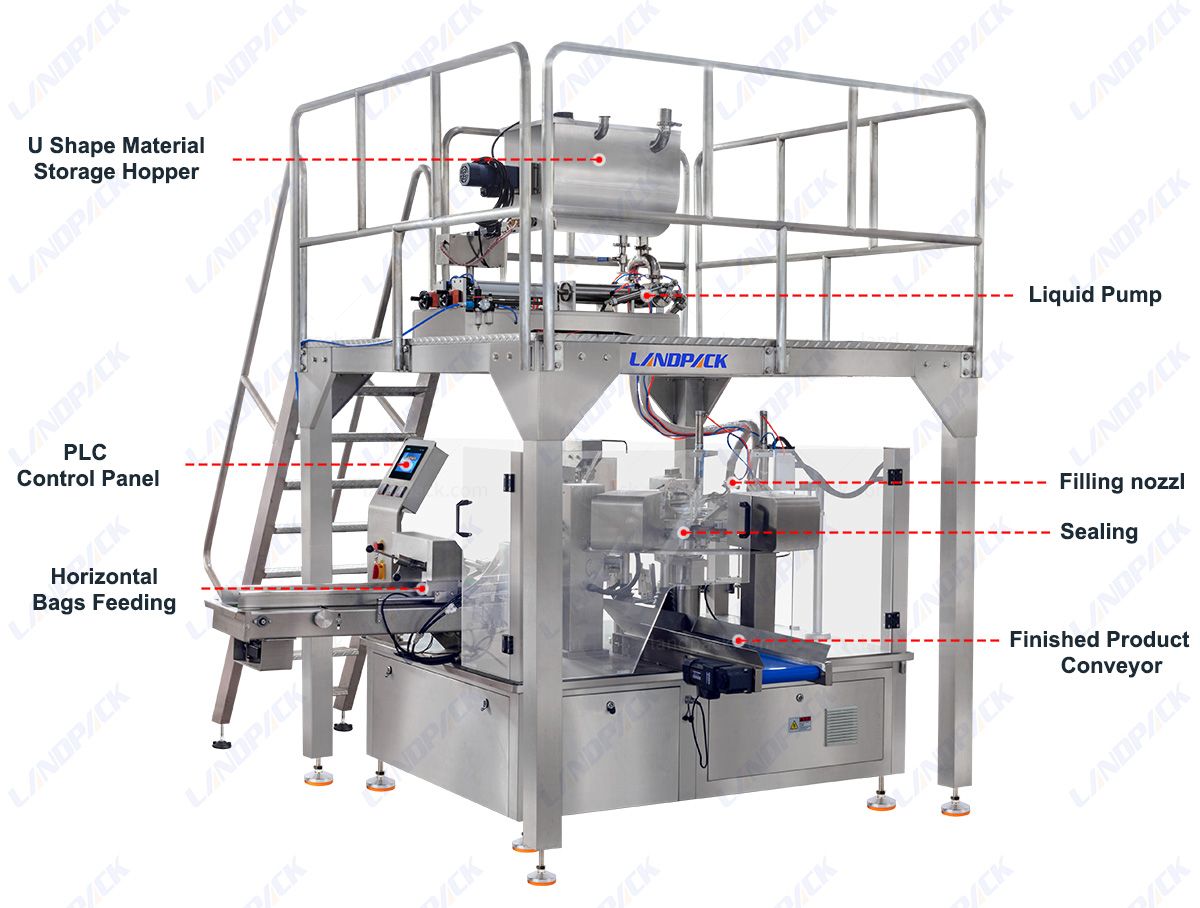

This 8-station vertical packaging machine features dual filling ports and a U-shaped storage hopper, enabling balanced liquid supply across all lanes.

Application:

Ideal for packaging a variety of viscous and free-flowing liquids, such as mayonnaise, tomato sauce, chili paste, and condiments — as well as personal-care liquids like shampoos, lotions, or liquid detergents.

Application:

Ideal for packaging a variety of viscous and free-flowing liquids, such as mayonnaise, tomato sauce, chili paste, and condiments — as well as personal-care liquids like shampoos, lotions, or liquid detergents.

Package Type:

This machine supports a variety of premade flexible pouch styles, including spout pouches, stand-up doypacks, three- or four-side seal bags, gusseted pouches, and zippered pouches. Its versatile feeding and sealing system adapts easily to different fitments and bag shapes.

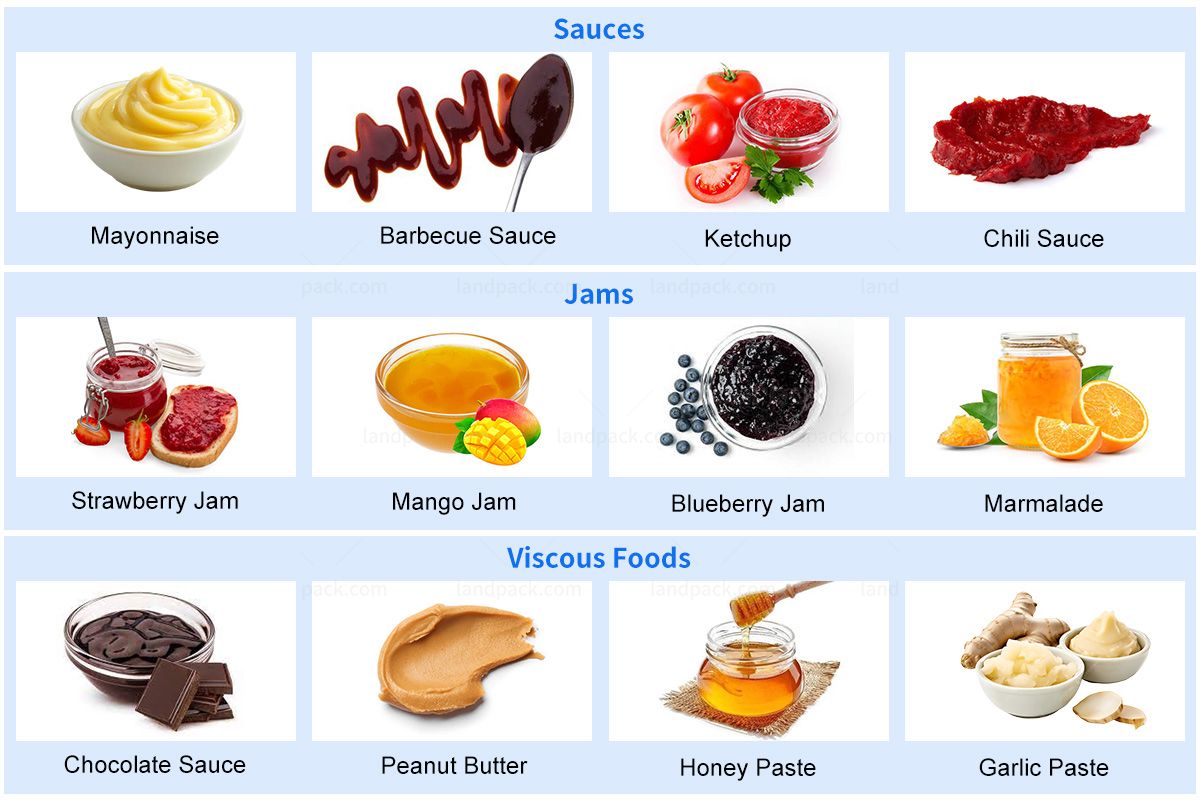

Suitable Products:

This 8-station premade pouch machine efficiently handles various liquid and semi-viscous products, such as:

Food Sauces & Condiments: Mayonnaise, ketchup, chili sauce, tomato paste, salad dressings, cooking oils, soy sauce, oyster sauce, curry paste, garlic paste.

Dairy & Beverage-Type Liquids: Yogurt, condensed milk, flavored syrups, fruit purees, smoothie bases, thick beverages, dessert sauces.

Household & Personal Care Liquids: Shampoo, conditioner, liquid soap, detergents, hand sanitizer gels, lotion, cosmetic creams, and daily-chemical liquid products.

Workflow:

This automatic spout-pouch filling machine is designed for efficient packaging of liquid and paste products. Its operation follows a smooth, fully automated sequence:

1. Pouch Loading – The system automatically picks up premade pouches and transfers them to each rotary station.

2. Coding Application – Inkjet or hot-stamping equipment marks required production information onto the pouch.

3. Pouch Opening – Vacuum suction and mechanical arms work together to open the pouch securely.

4. Liquid Dispensing – The filling nozzle delivers precise amounts of sauces, liquids, or viscous materials.

5. Spout Area Cleaning – The pouch opening is wiped clean to remove any residue before sealing.

6. Primary Heat Seal – The pouch receives its initial heat seal to begin closing the spout area.

7. Secondary Heat Seal – A reinforced sealing step ensures a firm, leak-resistant closure.

8. Product Discharge – Finished pouches are conveyed smoothly to the output belt for downstream packaging.

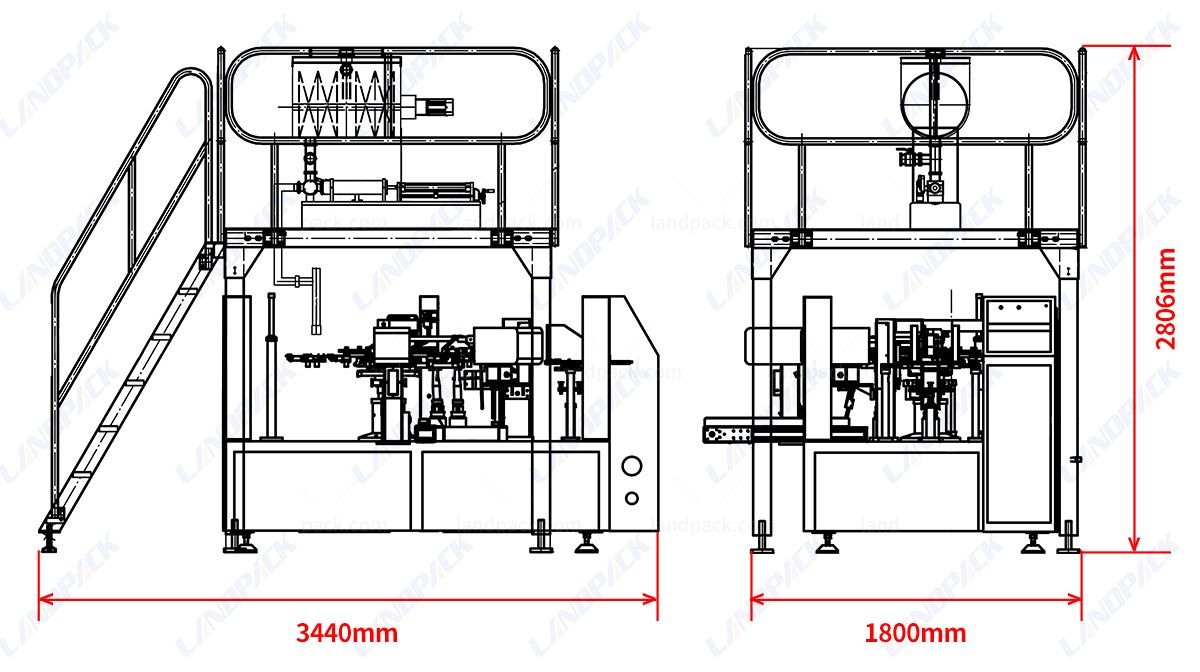

| Type | LD-8230 | LD-8260 | LD-8300 | LD-8400 |

| Bag Type | 3-side, 4-side sealing bag, stand-up bag, handbag, spout bags, zipper bag, compound bag, etc. | |||

| Bag Size(L*W) | W: 80-230mm, L: 150-380mm | W: 140-260mm, L: 150-380mm | W: 180-300mm, L: 150-430mm | W: 270-400mm, L: 200-500mm |

| Filling Range | 10-1000g | 1500g | 2000g | 3000g |

| Packing speed | 20-60 bags/min | 20-50 bags/min | 10-40 bags/min | 10-25 bags/min |

| Voltage | Standard AC380V+10%, three-phase 50HZ | |||

| Total Power | 3.75KW | 3.75KW | 3.85KW | 4.5KW |

| Air Consumption | 0.4m³/min | |||

| Dimensions | 1740*1380*1450mm(L*W*H) | 2460*1830*1460mm | 2260*2200*1520mm | |

| Machine Weight | 1300kg | 1300kg | 1700kg | 2000kg |

Machine Key Components:

1. Horizontal Bags Feeding

2. PLC Control Panel

3. U Shape Material Storage Hopper

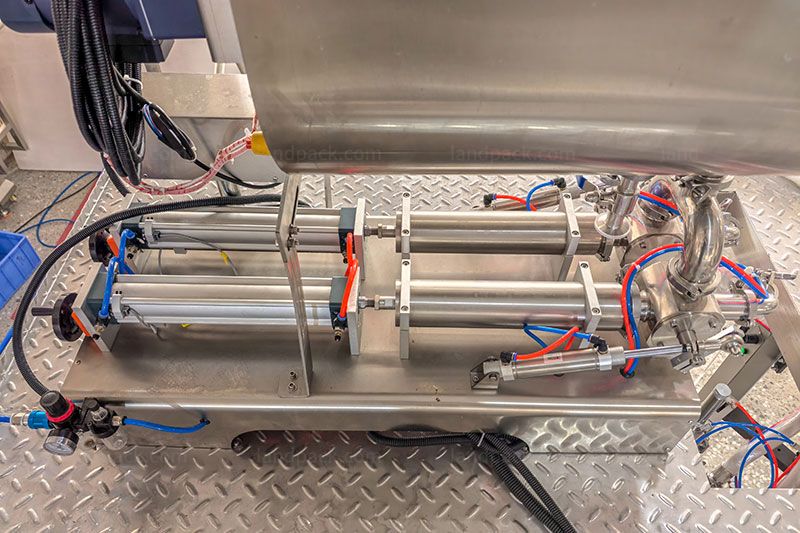

4. Liquid Pump

5. Filling Nozzl

6. Sealing Station

7. Finished Product Convevor

Feature:

U-Shaped Storage Hopper |  |

| Liquid Pump |

PLC Touchscreen Controller |  |

| Horizontal Pouch Feeding System |

Filling Nozzles |  |

| Heat-Sealing Unit |

| Output Conveyor The finished pouch conveyor delivers completed products smoothly to the next stage, maintaining a steady and organized production flow. |  |

Get Price & More Detail