Automatic Sauce/ Ketchup/ Paste Bottle Filling Capping And Labeling Machine

Model: LF-YX 600

Application:

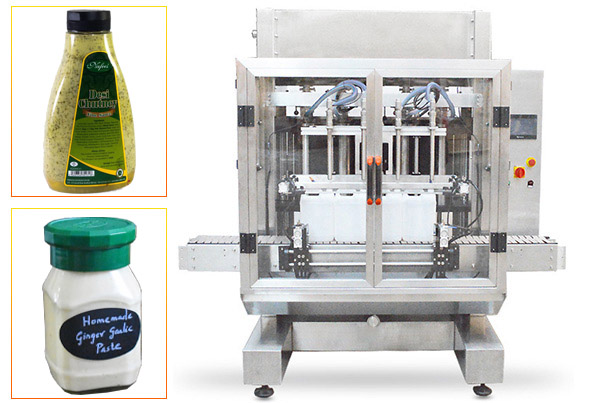

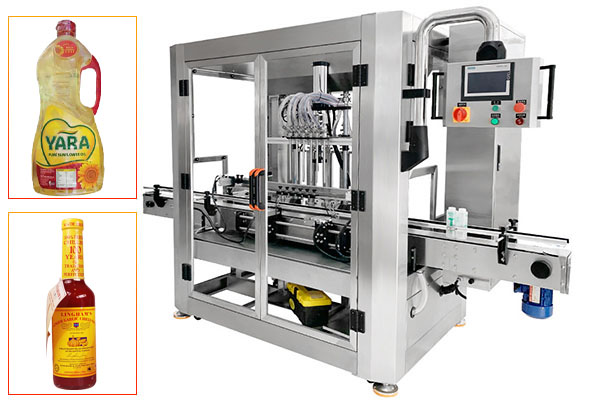

This production line is suitable for the filling of some large particle sauce products, such as: chili sauce, mushroom sauce, spicy sauce, seafood sauce, beef sauce, bean paste, tempeh sauce and other sauce products.

Advantage:

The production efficiency of this automatic chili sauce filling and capping production line is very high, which can reach thousands of bottles per hour, which is very suitable for the needs of some large-scale production enterprises.

Application:

This production line is suitable for the filling of some large particle sauce products, such as: chili sauce, mushroom sauce, spicy sauce, seafood sauce, beef sauce, bean paste, tempeh sauce and other sauce products. The production efficiency of this automatic chili sauce filling and capping production line is very high, which can reach thousands of bottles per hour, which is very suitable for the needs of some large-scale production enterprises.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

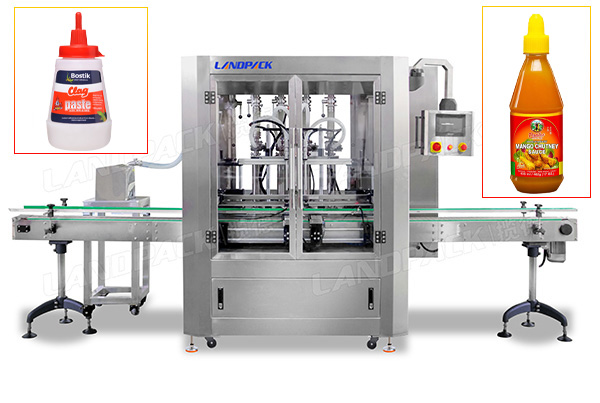

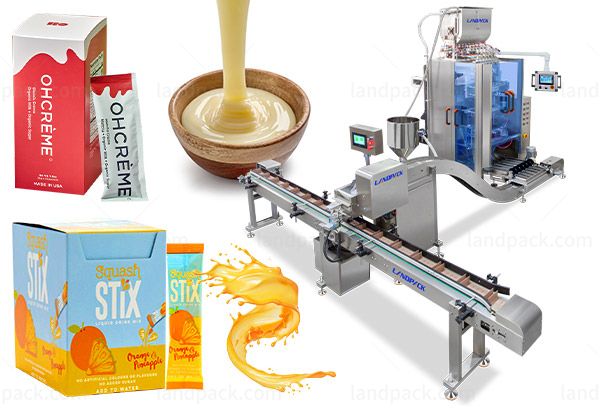

Packaging Samples

Model: LF-YX 600

Filling range: 100-300g, 100-500g, 500-2500g (optional)

Filling speed: 1200-3500 bottles/hour

Measurement accuracy: 2-4%g

Rated voltage: AC 380V 50Hz

Rated power: 3KW

Working air pressure: 0.6-0.8Mpa

Compatible bottle height range: 80-180mm

Material supply method: hoist/screw pump/diaphragm pump

1. Use professional servo motors at home and abroad to precisely control the speed of the motor to achieve the precise position movement of the quantitative cylinder;

2. Taiwan Delta or Germany Siemens programmable controller (PLC) and Taiwan Weilun touch screen terminal, the filling process is accurate and reliable;

3. The machine can be customized with various models of 4-12 heads according to different speed requirements of customers;

4. This production line uses a precise gear transmission system and a DC motor to allow the height of the bottle to be adjusted through the function of the high and low lifting buttons when switching bottles. This innovation makes it easier to use.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail