Paste Filling Capping Machine Line | Cosmetic Cream Lotion Liquid Filling Machine

Model: Filling Capping Machine Line

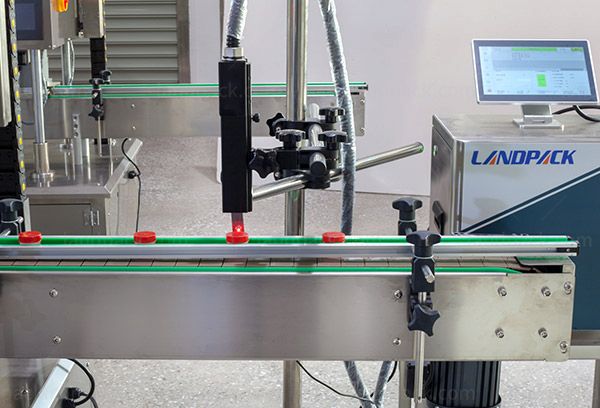

This liquid filling and capping line integrates a precision gear pump filler with a vibratory cap feeder, high-speed capping unit and inkjet coder for seamless production.

Application:

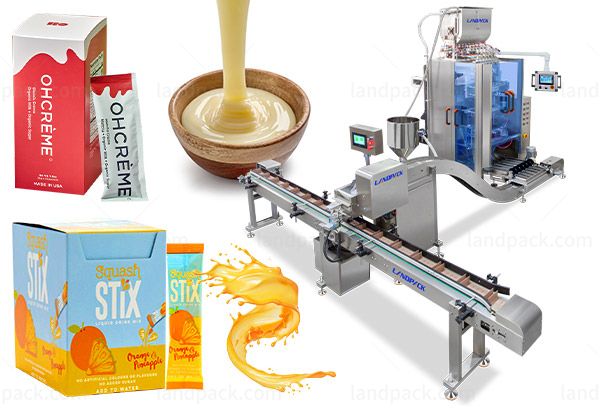

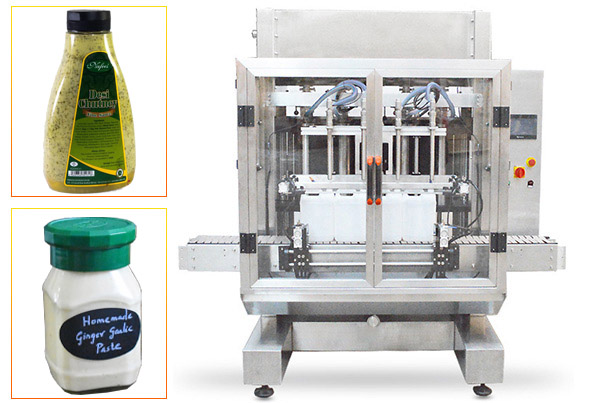

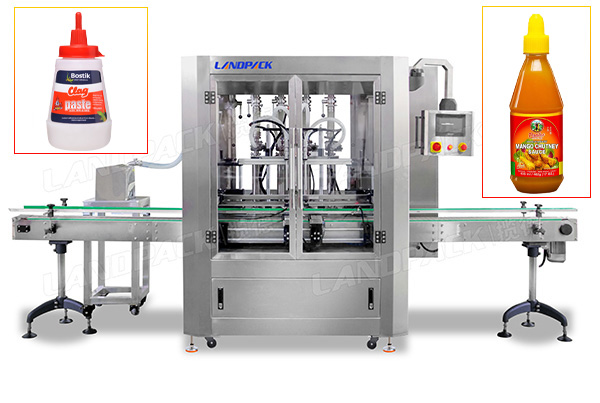

Engineered for manufacturers of viscous creams, sauces, lotions and other medium-to-high viscosity products, this filling and capping line ensures consistent volume accuracy across production runs.

Application:

Engineered for manufacturers of viscous creams, sauces, lotions and other medium-to-high viscosity products, this filling and capping line ensures consistent volume accuracy across production runs.

Package Type:

This liquid filling system is built specifically for bottle-based packaging, making it well-suited for creams, lotions, and other semi-viscous products in the cosmetics and pharmaceutical industries. It accommodates a broad variety of container types, including plastic, glass, PET, and HDPE bottles.

Suitable Products:

The cosmetic cream lotion filling machine—consisting of a bottle unscrambler, single-head gear pump filler, vibrating cap feeder, high-speed capping machine, and inkjet coder—is engineered for smooth, accurate, and hygienic filling of viscous products:

Personal Care & Cosmetics: facial creams, body lotion, moisturizing cream, cleansing gels.

Skincare Products: whitening cream, repair cream, anti-aging cream, sunscreen lotion.

Household & Daily Chemicals: hand cream, hand lotion, multipurpose soft creams.

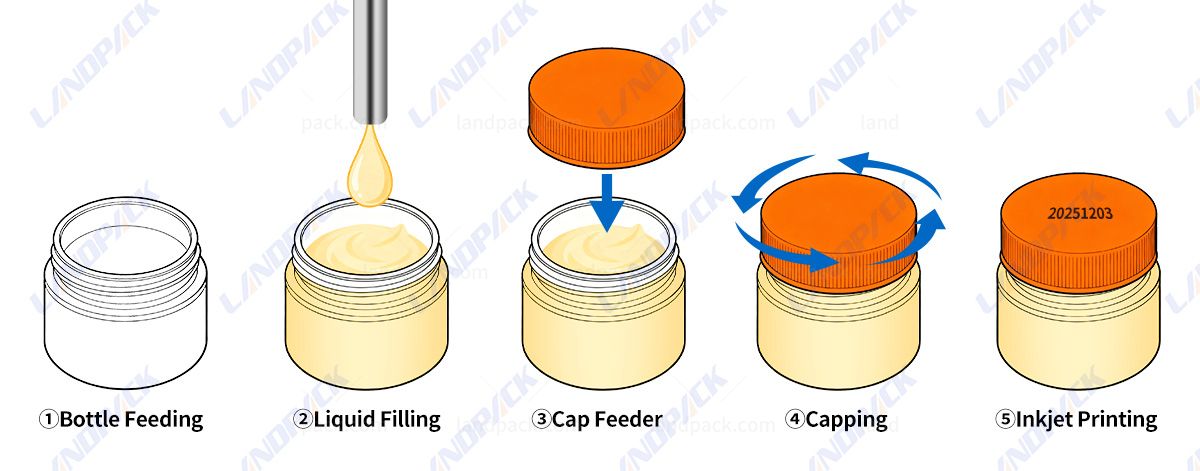

Workflow:

1. Bottle Sorting: The bottle unscrambler organizes empty containers and loads them onto the conveyor in a steady, continuous flow.

2. Cream Filling: The single-head gear pump dispenses precise amounts of cream into each bottle with consistent accuracy.

3. Cap Feeding: The vibration bowl orients the caps correctly and guides them to the capping area.

4. High-Speed Capping: The capping unit applies firm, uniform sealing torque to ensure each bottle is tightly closed.

5. Inkjet Coding: Before discharge, the inkjet printer prints production dates, batch codes, and other required identification onto the bottles.

| Bottle Liquid filling machine | |||||

| Model | LFZ-01/02/03/04 | LFZ-06 | LFZ-08 | LFZ-10 | LFZ-12 |

| Filling Range | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) | 50-1000ml (customizable) |

| Production Speed | <15-25 bottles/min | <20-35 bottles/min | <30-40 bottles/min | <40-50 bottles/min | <60 bottles/min |

| Measurement Accuracy | ±1% | ±1% | ±1% | ±1% | ±1% |

| Power | 2KW | 2.5KW | 3.5KW | 5KW | 5KW |

| Voltage | 220V, 50Hz | 220V, 50Hz | 220V, 50Hz | 220V, 50Hz | 220V, 50Hz |

| Air consumption | 0.6-8Mpa | 0.6-8Mpa | 0.6-8Mpa | 0.6-8Mpa | 0.6-8Mpa |

| Weight | 600kg | 650kg | 800kg | 800kg | 800kg |

| Dimension | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) | L4000*W1320*H2090(mm) |

| Automatic capping machine | |||

| Model | LFX-JX-01(Four wheel capping) | LFX-GS-150(Eight wheel capping) | LFX-GS-250(Six wheel capping) |

| Capacity | 20-50Bottles/min | 40-100Bottles/min | 30-80Bottles/min |

| Bottle cap diameter | Φ22mm-Φ80mm(Could be customized) | Φ18mm-Φ80mm(Could be customized) | Φ18mm-Φ80mm(Could be customized) |

| Bottle diameter | Φ35mm-Φ140mm(Could be customized) | Φ35mm-Φ140mm(Could be customized) | Φ35mm-Φ140mm(Could be customized) |

| Bottle sealing height | 38mm-300mm(Could be customized) | 38mm-300mm(Could be customized) | 38mm-300mm(Could be customized) |

| Power | 1.5KW | 2KW | 1.5KW |

| Voltage | 220V、50HZ | 220V、50HZ | 220V、50HZ |

| Air pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.5-0.7Mpa |

| weight | 250kg | 350kg | 300kg |

| Dimensions | H3000*W800*L1600mm | H3120*W1544*L2122 | H3100*W1244*L2122 |

| Inkjet Printer Machine | |

| Power supply | 220V 60Hz |

| Printing speed | 1024 seconds (5*7) |

| Printing materials | paper,plastic products,pipes,food bags,metal,glass, paper cups,etc. |

| Store information | The system can store 1000 print information |

| Machine size | length 370mm width 260mm height 500mm |

| Ink consumption | 70 million words per print (5*7) |

| Machine weight | 21kg |

| Package size | 560*350*570mm |

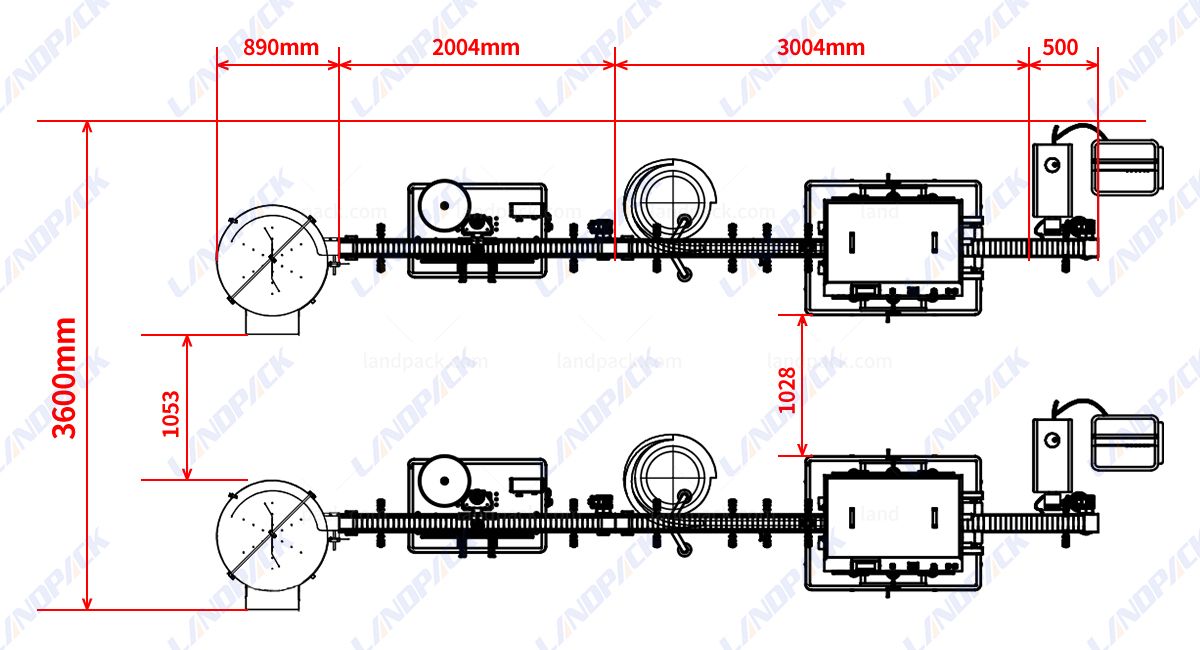

Machine Key Components:

1. Bottle Sorting Machine

2. Single Head Gears Pump Filling Machine

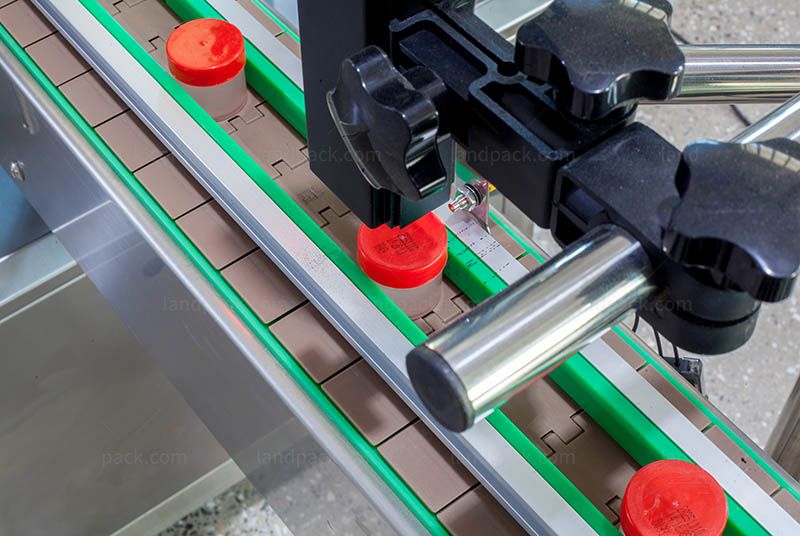

3. Vibrating Tray Cap Feeder

4. High-Speed Capping Machine

5. Inkjet Coding Machine

Feature:

Precision Gear Pump Filling Features a single-head gear pump engineered for consistent, precise dosing—ideal for medium to high-viscosity products such as creams and other thick formulations. |  |

| Easy Adjustments & Quick Changeover Operators can modify filling volume, speed, and key parameters directly on the interface without using tools, allowing fast transitions between various bottle types and sizes. |

Smooth Bottle and Cap Feeding The bottle arranging system and cap vibration bowl ensure steady, correctly oriented feeding of containers and caps, minimizing manual handling and reducing downtime. |  |

| Fast and Reliable Capping Performance The high-speed capping unit delivers consistent torque for tight, leak-free closures, perfectly suited for cosmetic and skincare packaging lines. |

Built-In Printing Module An integrated inkjet printer enables on-the-spot marking of production dates, batch numbers, and tracking information. |  |

| Durable Electrical Configuration Assembled with trusted, global-standard electrical components to guarantee long-term durability and stable machine operation. |

Get Price & More Detail