Protein Powder Stick Packing Machine | Automatic Counting Cartoning Packing System

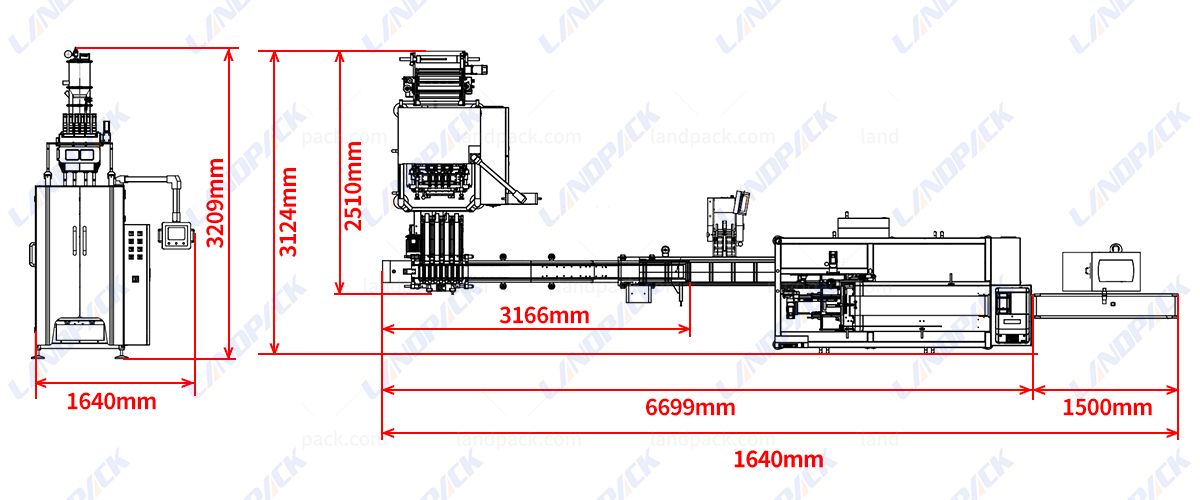

Model: LDBK-280-4

This multi-lane stick pack packaging machine is engineered for high-speed, precise powder dosing and sealing. Equipped with a vacuum feeder, auger filling system, and integrated coding device, it ensures stable performance and hygienic operation.

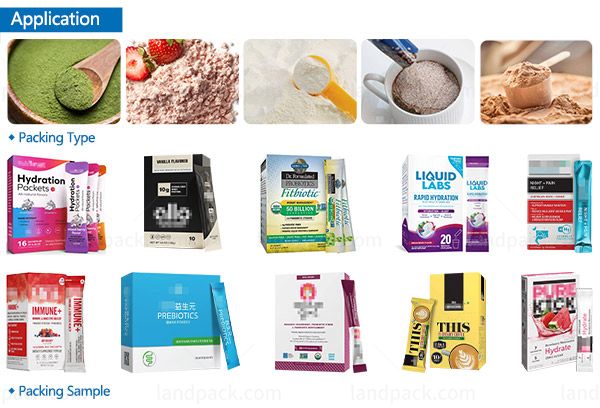

Application:

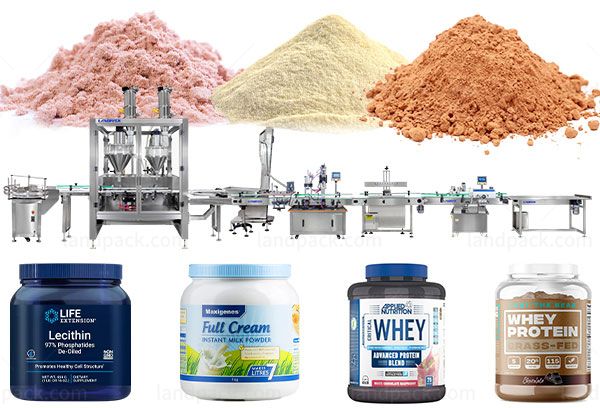

Ideal for packaging protein powder, milk powder, nutritional blends, instant beverage powders, and various pharmaceutical or dietary supplement powders.

Application:

Ideal for packaging protein powder, milk powder, nutritional blends, instant beverage powders, and various pharmaceutical or dietary supplement powders. Its multi-lane structure enables mass production of uniform single-serve stick packs, perfect for sports nutrition, health-care products, food industries, and on-the-go powder applications.

Package Type:

The multi-lane powder packaging machine produces a variety of slim, convenient, and single-serve package types. These package formats offer excellent portability, moisture protection, and professional, clean presentation for retail and travel-friendly products.

Suitable Products:

Its multi-lane structure enables mass production of uniform single-serve stick packs, perfect for sports nutrition, health-care products, food industries, and on-the-go powder applications.

- Nutritional & Beverage Powders: Protein powder, milk powder, collagen powder, instant coffee, cocoa mix, and energy drink powder—ideal for health, fitness, and daily nutrition markets.

- Food & Culinary Powders: Flour blends, seasoning powder, spices, sugar powder, baking mixes, and instant soup bases—supporting consistent dosing for food production.

- Pharmaceutical & Supplement Powders: Electrolyte powder, vitamin blends, oral rehydration salts, herbal extracts, and medical-grade fine powders—ensuring precise, hygienic stick-pack packaging for professional applications.

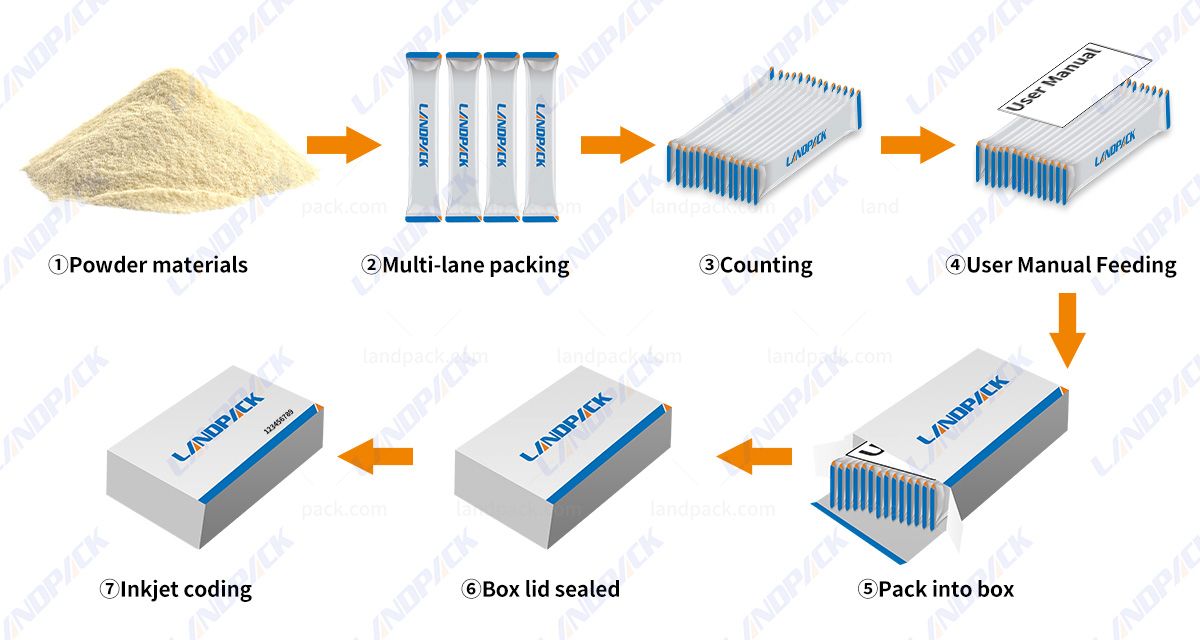

Workflow:

1. Powder materials feeding: Ensures steady and hygienic powder supply for continuous production.

2. Multi-lane packing: Simultaneously forms, fills, and seals multiple stick packs at high speed.

3. Stick pack counting: Automatically counts finished sticks with accuracy for downstream packing.

4. User manual feeding: Inserts instruction leaflets when required for retail or pharmaceutical use.

5. Carton opening: Automatically forms and opens cartons for fast, efficient loading.

6. Inkjet coding: Prints batch numbers, dates, or traceability information clearly on each carton.

7. Carton lid sealed: Securely seals the carton to protect the product during transport and storage.

8. Pack into box: Neatly packs sealed cartons into outer boxes, ready for shipment.

| Multi Lane Stick Packing Machine Parameters | ||

| Model | LDBK-280 | LDBK-560 |

| Lane number | 4-6 Line | 8-12 Line |

| Filling Method | 1.Volumetric cup; 2. Weigher | |

| Capacity | Max.35 cycle/ min | |

| Sachat Size | L:50-180mm; W:17-30mm | L:50-180mm; W:17-30mm |

| Film weidth & Thickness | Max.280mm, 0.07-0.10mm | Max.560mm, 0.07-0.10mm |

| Sealing type | Back sealing/Stick bag | Back sealing/Stick bag |

| Cutting type | 1.Straight cutting; 2.Zig zag cutting; 3.Round cutting; 4.Irregular | |

| Air & Powder | 0.8Mpa 0.8m3/min; 3.5kw | 0.8Mpa 0.8m3/min; 5.5kw |

| Dimension & weight | 1385*918*2005mm;350kg | 1685*1300*2005mm;550kg |

| Automatic Bag in Box Packing System | |||

| Model | LDDS-100 | LDDS-120 | LDDS-250 |

| Packing Speed | 40-60 boxes/min | 30-50 boxes/min | |

| Box Size | (L)60-220mm*(W)20-125mm*(H)15-60mm | (L)80-250mm*(W)100-160mm*(H)40-90mm | (L)150-320mm*(W)100-180mm*(H)90-110mm |

| Air Consumption | ≥0.6 mpa, 20 m³/h | ||

| Power Supply | 220V/380V, 50HZ | ||

| Machine Power | 4.5KW | 5.5KW | 6.5KW |

| Machine Size | 3425*1390*1771mm | 3450*1450*1800mm | 4200*1650*1850mm |

| Machine Weight | 1200KG | 1600KG | 2500KG |

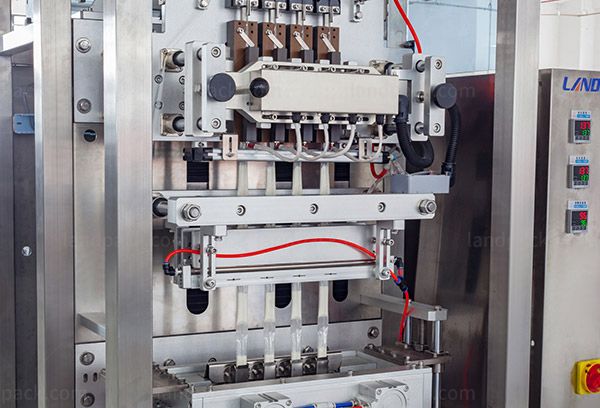

Machine Key Components:

1. Vaccum Feeder

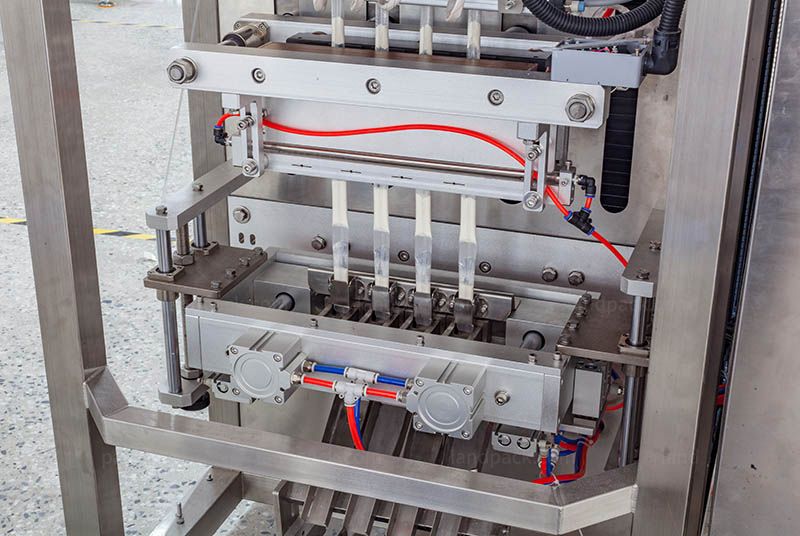

2. Fully Automatic Multi Lane Packing Machine

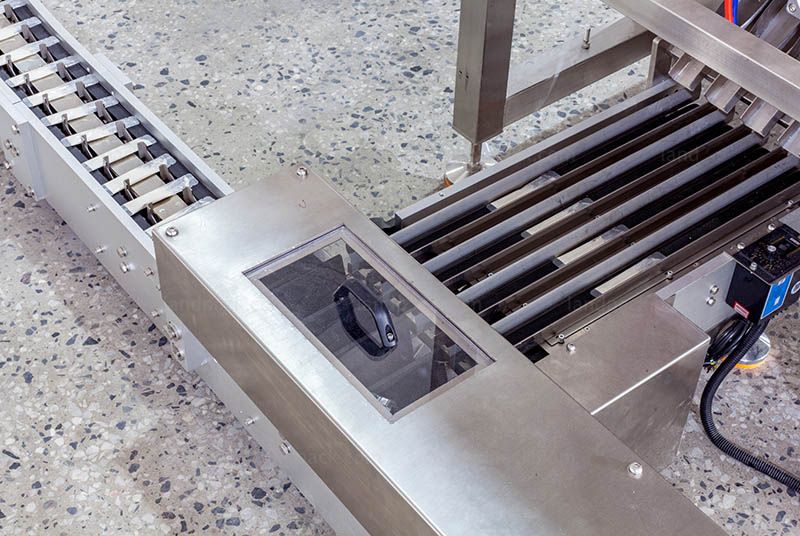

3. Inclined Feeder

4. User Manual Feeding

5. Gift Box Pick Up

6. Folding & Inserting Box to Close it

7. Clamp Belt

8. Finished Box Inject Printer Belt

Feature:

High-Efficiency Multi-Lane Stick Pack Machine The LDBK-280 operates with impressive speed and precision, continuously forming, dosing, sealing, and cutting stick packs for powder products. Designed for fine materials such as whey protein, instant coffee, nutritional powders, and micro-granules, its servo-controlled auger guarantees stable filling accuracy and reliable seal integrity even at high output rates. |  |

| Vacuum Conveying for Dust-Free Powder Supply A fully automated vacuum transfer system feeds powder directly into the dosing hopper, reducing airborne dust and preventing material loss. This closed-loop handling method keeps the production environment clean and is especially suitable for ultra-light powders that disperse easily. |

Inclined Conveyor for Steady Stick Pack Delivery The angled belt conveyor arranges finished stick packs neatly and guides them smoothly toward downstream cartoning equipment. Its optimized belt structure minimizes friction and eliminates issues like warping, slipping, or uneven feeding during fast-paced production. |  |

| Automatic Cartoning with Instruction Insert The automatic cartoner erects cartons, loads groups of stick packs, inserts instruction leaflets via a dedicated mechanism, and completes final closing—all in a synchronized, uninterrupted cycle. This ensures tidy packaging and enhanced user convenience. |

Coding Integration for Complete Product Tracking A dedicated coding conveyor paired with a compact inkjet system marks each carton with production dates, lot codes, and other traceability information. The clear, high-contrast printing meets international compliance standards for food, health supplements, and pharmaceutical products. |  |

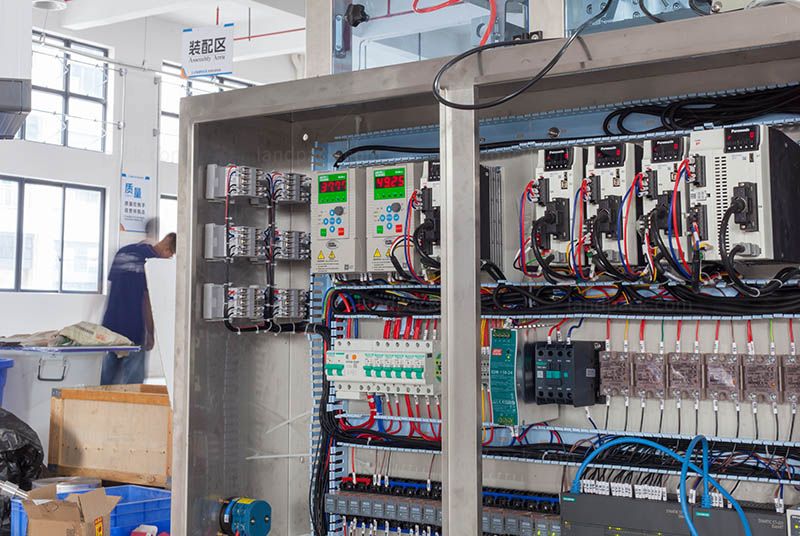

| Intelligent Electrical Control Cabinet for Stable System Performance The integrated electrical control cabinet houses all core automation components, ensuring safe, organized, and reliable machine operation. Equipped with high-quality circuit protection, modular wiring, and an intuitive PLC interface, it allows operators to monitor system status in real time and make quick adjustments when needed. Its heat-dissipation design and clean internal layout reduce maintenance requirements and enhance long-term durability, supporting continuous high-speed production with confidence. |

Get Price & More Detail