Automatic Reagent Test Tube/ Antiviral Liquid Filling Machine

Model: LFF-AT-02

Application:

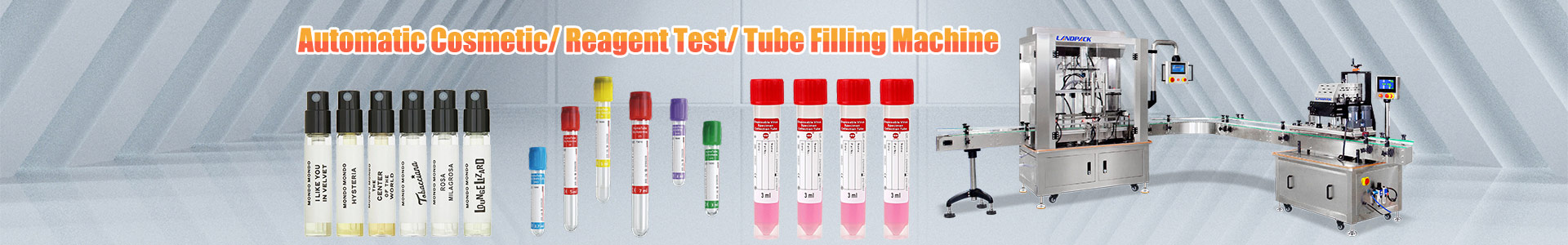

Widely used in pharmaceutical factories, such as: reagents, plastic test tubes, eye drops, e-liquid, essential oils, and other small bottled products.

Application:

Automatic reagent test tube/ antiviral liquid filling machine, it is widely used in pharmaceutical factories, such as: reagents, plastic test tubes, eye drops, e-liquid, essential oils, and other small bottled products..

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

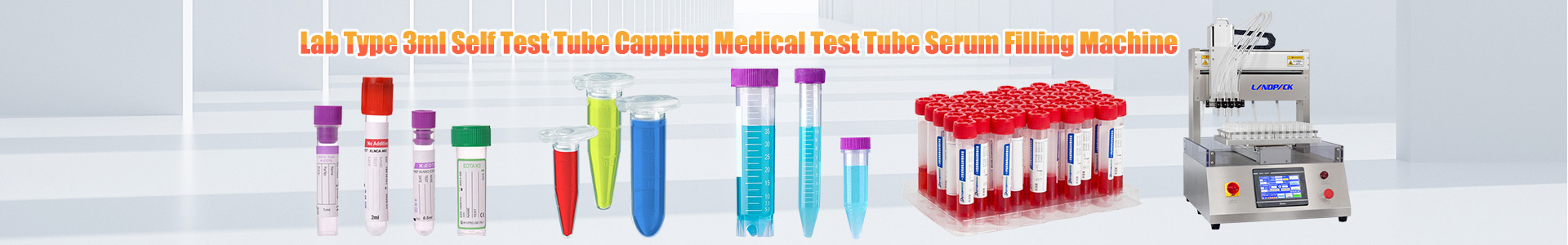

Packaging Samples

| Model | LFF-AT-02 |

| Suitable for tube size | according to the sample provided by the customer, it can be customized |

| How to organize the pipes | manually place the pipes on the pipe-organizing machine |

| Out of the tube | according to the shape of the tube, actual customization |

| Filling method | 2 heads peristaltic pump filling |

| Filling capacity | 3ml~8ml |

| Output | about 2400 bottles/hour |

| The way to arrange the cap | automatic lid arrangement with vibration plate (double vibration plate) |

| Cap removal/cap removal method | automatic cap removal, servo torque capping (double-head servo, torque capping) |

| Labeling | automatic positioning and labeling |

| Pipe-out method | the cylinder grabs the pipe and moves the pipe, and the pipe is discharged through the slope |

| Program control | touch screen |

| Air pressure | 0.6-0.8MPa |

| Power | about 3KW/AC220V 50/60HZ |

1.The equipment adopts a gas-electric integration and PLC system control, and is easy to operate. It is an ideal reagent filling equipment that fully meets the production specifications of the drug tube.

2.The equipment adopts high-precision peristaltic pump for quantitative filling, with high filling accuracy and beautiful effect.

3.The servo motor is used to grasp the cap and screw the cap, which can accurately grasp the 1.force of the cap screw to protect the cap and prevent the cap from being scratched and not screwed tightly.

4.It can be equipped with automatic labeling function, visual inspection function, automatic boxing and other functions.

5.The operation of the machine is equipped with safety guarantees, fault alarms and other settings. The automatic operation of functions from pipe entry, filling, cap sorting, capping, capping, labeling, and collection, does not require manual intervention.

6.The operation of the machine is equipped with safety guarantees, fault alarms and other settings. The automatic operation of functions from pipe entry, filling, cap sorting, capping, capping, labeling, and collection, does not require manual intervention.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail