High-Precision Reagent Tube Swab Sampling Tube Liquid Filling Capping Machine

Model: LFYT-01

Application:

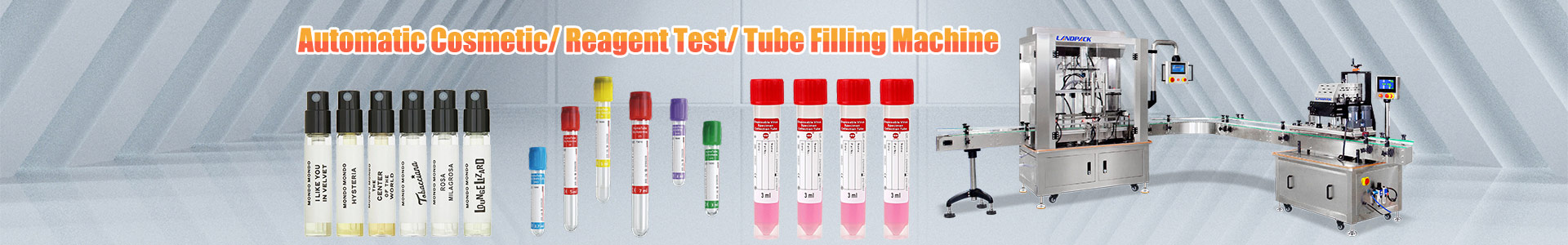

It is suitable for the filling of various liquids, various swab sampling tube extraction tube nucleic acid test sample tube nutrient solution.

Application:

High-precision reagent tube swab sampling tube liquid filling capping machine, it is It is suitable for the filling of various liquids, various swab sampling tube extraction tube nucleic acid test sample tube nutrient solution.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

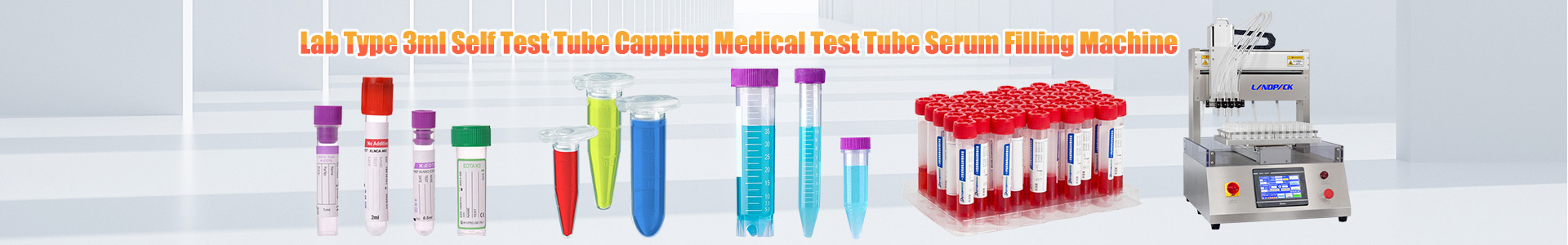

Packaging Samples

| Model | LFYT-01 |

Sealing speed | 0-60 bottles/min(customized) |

Accuracy | 0.25% |

Filling type | Ceramic plunger pump |

Power | 50-60Hz |

Control | Simen PLC+Touch screen, Multilanguage support |

Quantity of filing heads | 4/6/8/10/12(customized) |

Filling range | 0.2-25ML |

Weight | 41 KG |

Size | About 500*550*580mm |

1. The ceramic pump filling machine is a high-accuracy filling machine. Widely used in advanced cosmetics, skin care products, pharmaceuticals. High installation accuracy, convenient and flexible use;

2. Equipped with no bottle and no filling function, the liquid level automatically controls feeding, effectively reducing equipment failure;

3. Program control adopts PLC + touch screen manual operation interface to realize intelligent control

4. The filling nozzle is made of stainless steel 304, which is corrosion-resistant and meets GMP production requirements;

5. The material of the feeding hose is PVC, the temperature range: -10 ℃ ~ + 90 ℃;

6. PLC touch screen control panel, visualization of working parameters, simple operation interface, and the fastest basis for machine conditions. 15 different national operating languages for wider applicability.

7. Using a ceramic column pump with higher metering accuracy can ensure that the filling error is below 0.25%

8. The size of the tray and the number of filling heads can be customized according to the needs of filling

9. The drawer type design makes the circuit layout of the machine clearer and easier to maintain. Reasonable circuit distribution greatly improves the stability of the machine

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail