Fastener Plastic Hardware Visual Counting Packing Machine

Model: LP-Series Industrial Counting Wrapper

High precision hardware visual counting packing machine for plastic fasteners. Automatic fastener packing machine and hardware packaging machine, up to 50 bags/min.

Application:

This machine is suitable for automatic counting and packaging of small hardware parts such as plastic fasteners, screws, bolts, nuts, washers, clips, pins, and other tiny industrial components.

Application:

This machine is suitable for automatic counting and packaging of small hardware parts such as plastic fasteners, screws, bolts, nuts, washers, clips, pins, and other tiny industrial components. It is widely used in hardware, fastener, and industrial accessory packaging applications.

Package Type:

Engineered for precision, this vision-based counting and bagging system supports an extensive array of flexible formats. It ensures the exact counting and sealing of small components into pillow, flat, or laminated pouches (PE/PP), meeting the rigorous demands of industrial hardware packaging.

Suitable Products:

This hardware visual counting packing machine is suitable for accurate visual counting and packaging of a wide range of small plastic and metal parts. Designed as a reliable fastener packing machine, it ensures precise quantity control, stable operation, and consistent packaging quality across multiple industries.

Plastic & Metal Parts: Fasteners, Small hardware, Washers, Plastic Connectors

Furniture Hardware: Small connectors Cable clips Torpedo level Plastic parts

Others: Pharmaceutical Items, Snack, Electronic components, Building blocks

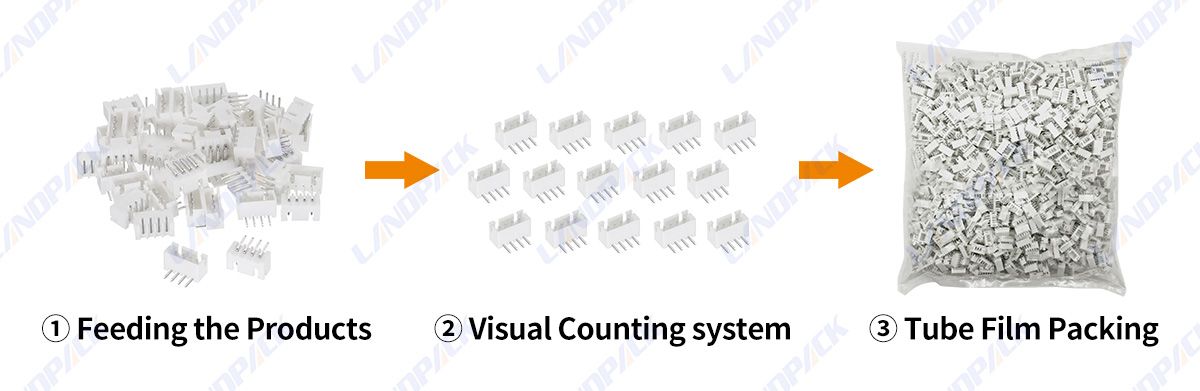

Workflow:

1. Material Feeding: Fasteners and hardware are mechanically fed into the processing stream.

2. Products Visual Counting: Every unit is accurately tallied to ensure exact quantities per pack.

3. Products Filling: Hardware is systematically transferred into the packaging station.

4. Tube Film Filling & Sealing: The system performs integrated film forming, filling, and sealing from tubular stock.

5. Output: Completed pouches are exited for bulk collection or downstream processing.

| Machine Model | LP-Series Industrial Counting Wrapper |

| Counting System | High-Speed Fiber Optic / Infrared Sensing |

| Feeding Method | Automatic Vibratory Bowl (Customized track) |

| Packaging Material | PE (Polyethylene), OPP/CPP, PET/PE |

| Bag Width | 30mm - 150mm (Adjustable) |

| Bag Length | 50mm - 200mm (Adjustable) |

| Packing Speed | 10 - 50 bags/min (Subject to material quantity) |

| Counting Accuracy | ≥ 99.8% |

| Sealing Type | Center Back Seal / 3-Side Seal |

| Control Interface | 7" Multi-language Color PLC Touch Screen |

| Air Pressure | 0.5 - 0.7 MPa |

| Power Rating | 2.5 KW / 220V 50-60Hz |

| Conveyor System | Included (Finished product discharge belt) |

Machine Key Components:

Feature:

1. High-Speed Vision Logic: Utilizing 10,000 scans/sec, the system ensures flawless counting unaffected by mass or density fluctuations.

2. Precision Feed Control: A multi-stage vibratory system with dual coarse/fine tuning guarantees exact dosing accuracy.

3. Smart Self-Calibration: The autonomous learning module streamlines setup and minimizes manual parameter configuration.

4. Recipe Management: Stores multiple product profiles to enable instantaneous changeovers between different materials.

5. One-Touch Purge: Features an automatic residual clearing function to prevent cross-contamination during product swaps.

6. Total Traceability: Supports ERP integration and localized data logging for comprehensive production transparency.

7. Zero-Shortage Guard: Guarantees 100% fill accuracy; surplus units are automatically recirculated to prevent under-counts.

8. Intelligent Diagnostics: Real-time monitoring for foreign matter detection, material levels, and operational anomalies.

9. Clog-Free Hopper: An open-gate architecture prevents material bridging and ensures uninterrupted flow.

Get Price & More Detail