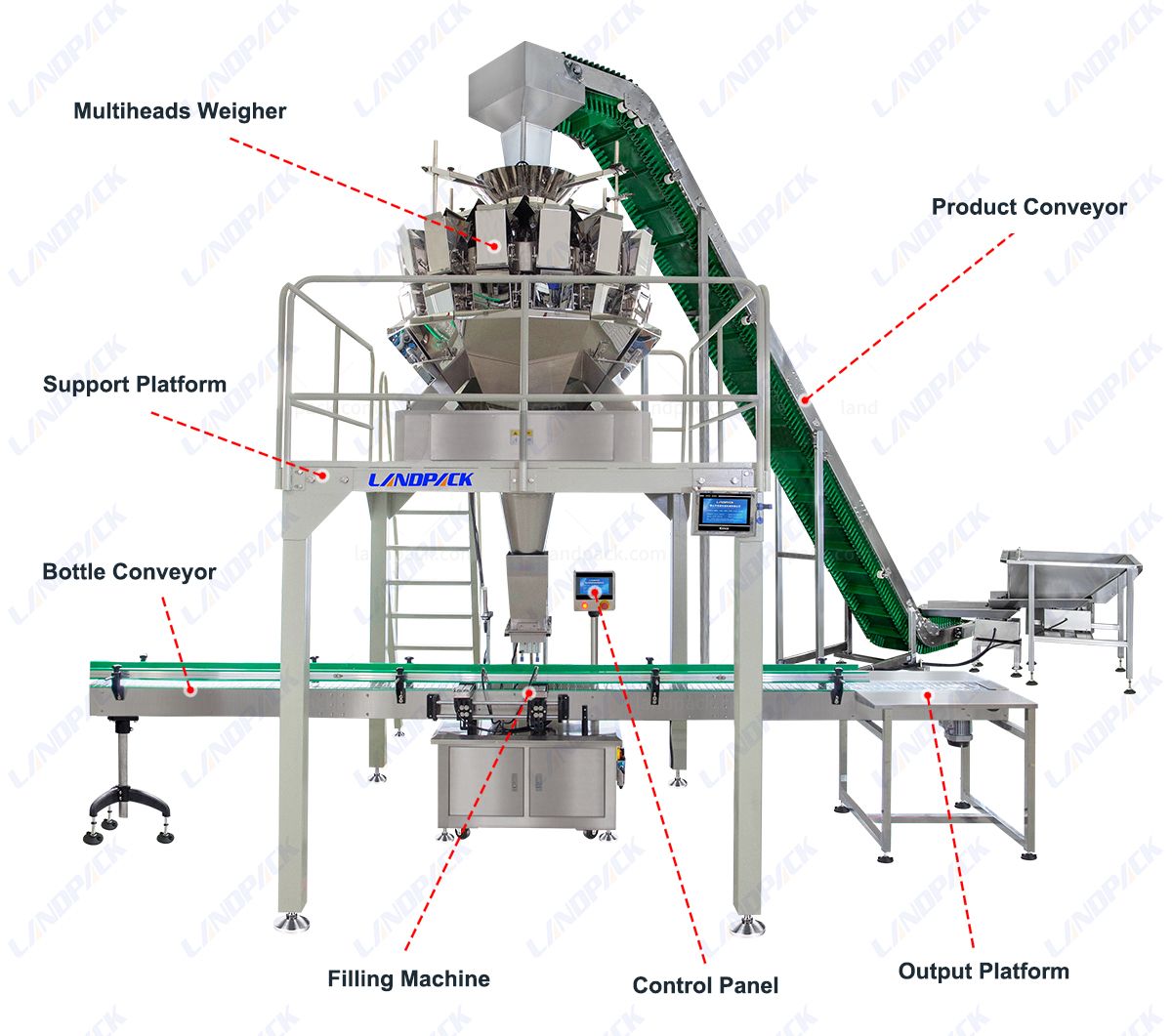

Automatic Fastener Weighing Packing Machine Box Filling Machine

Model: LFZX-900

Minimize giveaway and maximize throughput with this state-of-the-art integrated solution designed specifically for the demanding hardware industry.

Application:

Our packaging machine is expertly designed to handle a diverse array of loose, small, and medium-sized hardware and industrial components.

Application:

Our packaging machine is expertly designed to handle a diverse array of loose, small, and medium-sized hardware and industrial components.

Package Type:

The machine's discharge mechanism is configured for precise, high-speed dispensing into a wide range of rigid and semi-rigid containers, including: Boxes, Cases, Bottles & Jars, Tubs, etc.

Suitable Products:

The precision weighing and gentle handling system makes it ideal for:

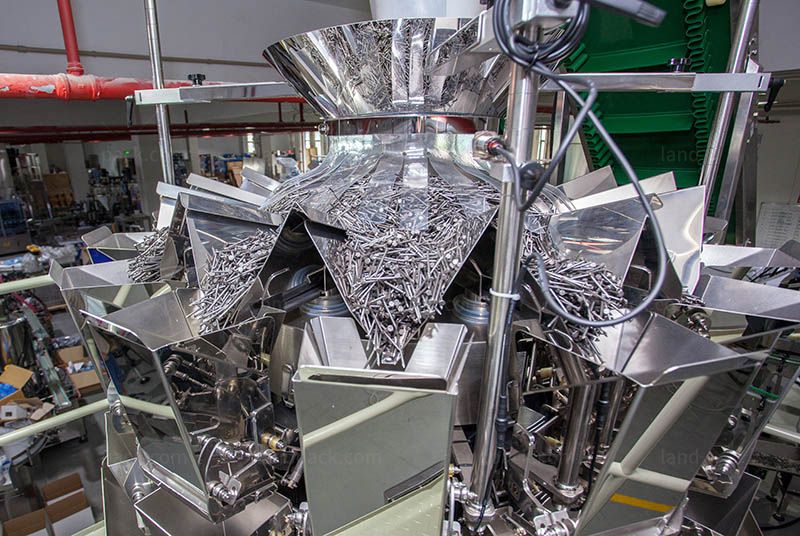

Fasteners: Screws, bolts, nuts, washers, anchors, rivets.

Furniture/Cabinet Fittings: Hinges, handles, drawer slides, connectors, knockdown fittings.

Small Parts & Accessories: Nails, pins, small brackets, electronic components, plastic plugs.

Kits & Sets: Assortment packaging for various mixed components in a single box.

Workflow:

1. Material Loading & Elevation: Hardware parts are loaded into the main hopper and transported vertically by the Chain Plate Bucket Elevator (Cleated Conveyor).

2. Product Weighing: The Multi-Head Electronic Weigher receives the product and rapidly combines material from multiple weigh buckets to achieve the exact target weight.

3. Container Positioning: Empty boxes, cartons, or containers are indexed and accurately positioned beneath the weigher's discharge chute using a conveyor system.

4. Product Filling: The precisely weighed material is discharged simultaneously from the weigher's buckets through a funnel into the waiting container.

5. Package Output: The filled container is automatically moved away from the filling station onto the downstream conveyor.

| Model | LFZX-900 |

| Speed | 10-20 boxes/min |

| Packing Size | Customizable |

| Control system | PLC |

| Power supply | 220V, 50Hz |

| Dimension | 2000*700*1200mm(L*W*H) |

| Equipment material | 304 |

| Weight | 150KG |

| Description of the main packaging process | Box feeding-weighing-feeding-out of box |

Machine Key Components:

1. Product Conveyor

2. Multiheads Weigher

3. Support Platform

4. Bottle Conveyor

5. Filling Machine

6. Control Panel

7. Output Platform

Feature:

Nail Collator High-Speed Collation: Automatically sorts, aligns, and links nails into coiled or strip formats using a highly precise mechanism. |  |

| Chain Plate Bucket Elevator Gentle Vertical Transfer: Features robust chain plates and durable buckets for the vertical elevation of bulk and heavy hardware items. |

Multi-Head Electronic Weigher Ultimate Weighing Accuracy: Utilizes multiple independent load cells and advanced combination algorithms to select the exact target weight. |  |

| Filling Section Precision Discharge: Employs a dedicated funnel and chute system designed for splash-free, direct filling into rigid containers. |

PLC Control System Centralized Automation: Uses an industrial-grade PLC and an intuitive HMI touchscreen for fully synchronized control of all machine components. |  |

Get Price & More Detail