Automatic Coffee Mate Bottle Filling Machine Line

Model : LD-PAF01

Introduce :

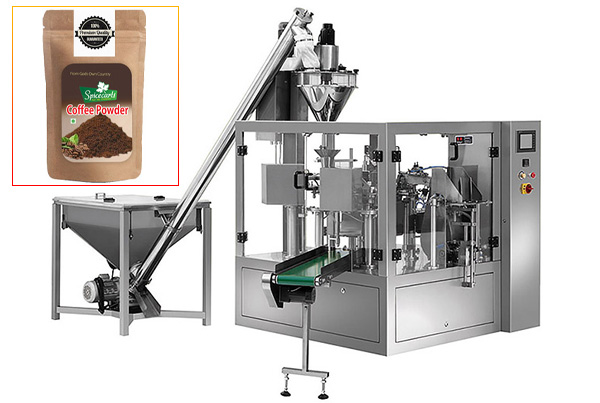

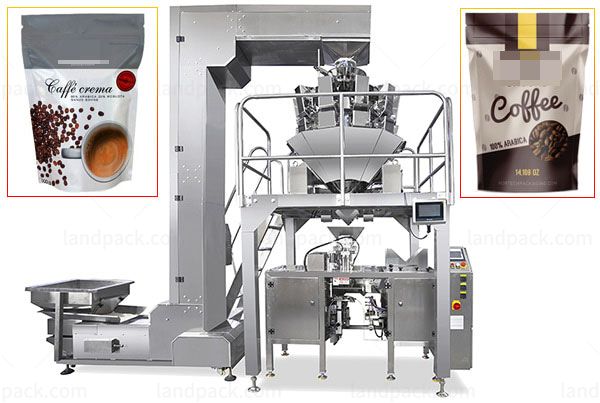

It's dual auger screw system ensures precise dosing, while the integrated vacuum feeder and dust removal features maintain a clean workspace. This compact line suits industries such as food, pharmaceuticals, and cosmetics, offering efficient and accurate packaging solutions for both free-flowing and non-free-flowing powders..

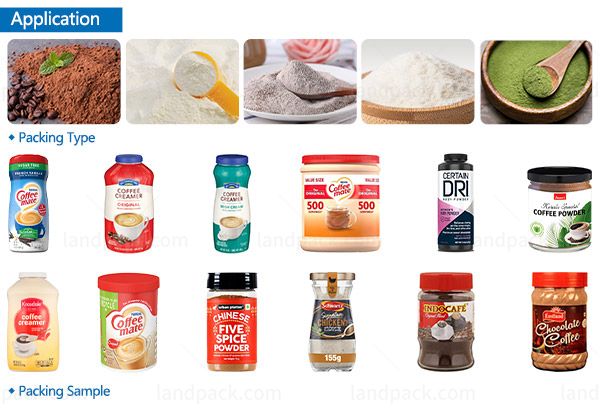

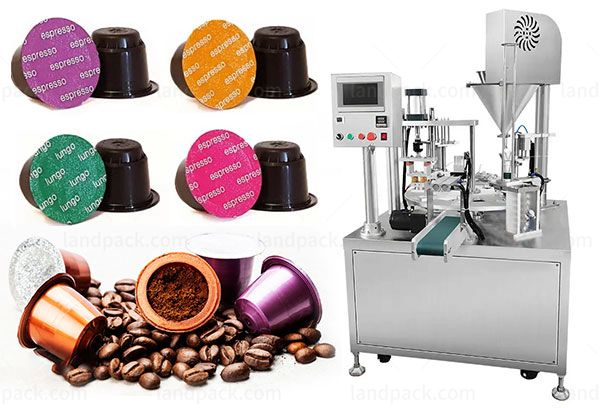

Application :

This Bottle Filling Line is ideal for automating the filling, capping, and sealing of various powdered products, including coffee creamer, milk powder, protein powder, and nutritional supplements.

Types of Bottle :

Plastic bottles, glass bottles, aluminum bottles, metal cans, custom-shaped bottles.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Samples :

| Automatic Powder Weighing Filling Machine | |||

Model | LFP-01 (Single Head Powder Filling) | LFP-01 (Single Head Powder Filling) | LFPD-50-30 (Double Head Powder Filling) |

Filling Weight | 10-5000g | 10-5000g | 100-2000g |

| Bottle Diameter | Ф30-Ф140mm | Ф30-Ф140mm | Ф60-Ф135mm |

| Bottle Height | 50mm-200mm | 50mm-200mm | 60-260mm |

Filling Speed | 10-20 bottles/min | 20-40 bottles/min | 10-25 bottles/min |

Measurement accuracy | <500g,<±1%,>500g,<±0.5% | 100-1000g,≤±2g;>1000g,<±5g | |

Power | 2.5 KW | 5 KW | 4.5 KW |

| High Speed Capping Machine | |||

| Model | LFX-GS-150 (Eight wheel capping) | LFX-GS-250 (Six wheel capping) | |

| Capacity | 40-100 bottles/min | 30-80 bottles/min | |

| Bottle cap diameter | Ф18mm-Ф80mm (Could be customized) | ||

| Bottle diameter | Ф35mm-Ф140mm (Could be customized) | ||

| Bottle sealing height | 38mm-300mm (Could be customized) | ||

| Power | 2KW | 1.5KW | |

| Voltage | 220V, 50HZ | ||

| Air pressure | 0.6-0.8Mpa | 0.5-0.7Mpa | |

| Weight | 350kg | 300kg | |

| Dimensions | H3120*W1544*L2122 mm | H3100*W1244*L2122 mm | |

| Automatic Aluminum Foil Sealing Machine | |||

| Model | LD-ZS (Double Heads Aluminum Foil Sealing) | LF-LB-2000 (Single Heads Aluminum Foil Sealing) | |

| Applicable bottle diameter | Ф10-200mm(Could be customized) | ||

| Applicable bottle height | H: 40-300mm (Could be customized) | ||

| Speed | 0-30 bottles/min | 0-10 bottles/min | |

| Bottle material | Glass, ceramics, plastics, metals | ||

| Voltage | 220V, 50HZ, 1500W | 220V, 50HZ, 1200W | |

| Dimension | 1500*800*1750mm | 1200*600*1550mm | |

1. The dual auger filling system with integrated weight check ensures high-precision dosing for powders like coffee creamer, milk powder, and protein powder, achieving ±1% accuracy.

2. A compact vacuum feeder (under 3m height) enables efficient material transfer with minimal manual handling, optimizing space and workflow.

3. Equipped with a vacuum dust removal system to maintain a clean workspace by minimizing powder contamination during filling.

4. User-friendly HMI touch screen supports multiple languages, simplifying operation for new businesses and reducing training time.

5. The integrated line includes bottle feeding, capping, aluminum foil sealing, and collection, streamlining the entire packaging process.

6. High-speed filling at 20–35 bottles per minute with consistent ±1% accuracy, suitable for demanding production schedules.

7. Versatile for food, pharmaceutical, and cosmetic industries, handling diverse powdered products from fine coffee to coarse additives.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail