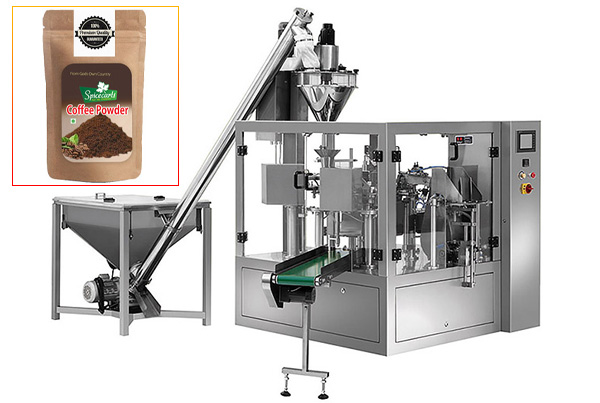

Automatic Coffee Capsules Filling Sealing Machine

Model: Coffee Powder Capsule Packing Machine

Specially engineered to provide precise dosing and airtight sealing of espresso coffee, flavored coffees, milk powder, tea powder and hot chocolate powder in order to preserve freshness and extend shelf life.

Application:

Coffee cup sealing machines are highly versatile and can be used to package a wide range of materials, primarily in the food and beverage industry. Such as Coffee powder, tea powder, cocoa powder, milk powder, etc.

What is a Capsule Filling Sealing Machine?

A capsule filling and sealing machine is an automated device designed to accurately fill empty capsule shells with various substances—such as powders, granules, pellets, or liquids—and then securely seal the capsule's cap and body together.

Packaging Style:

Supports popular capsule formats such as Nespresso, K-Cup, Dolce Gusto, Lavazza etc. Offers options for pre-cut lids or heat/rolled film sealing.

Suitable Industry:

It is a versatile solution suitable for filling a wide range of products, including:

*Ground Coffee – Espresso, single-origin coffee, blends, flavored coffee

*Tea Powder & Leaf Tea – Instant tea powder, matcha, herbal tea, loose leaf tea (with filter capsules)

*Hot Chocolate & Cocoa Powder – Single-serve hot chocolate pods

*Milk Powder & Creamer – Dairy or non-dairy creamers for coffee/tea

*Protein & Nutritional Powder – Whey protein, collagen powder, meal replacement blends

*Functional Drinks & Supplements – Energy drink powder, dietary supplements, health powders

*Spices & Seasonings – Ground spices, seasoning blends for single-serve use

*Powdered Medicine or Nutraceuticals – Nutritional supplements in single-serve pods (where food-grade standards apply)

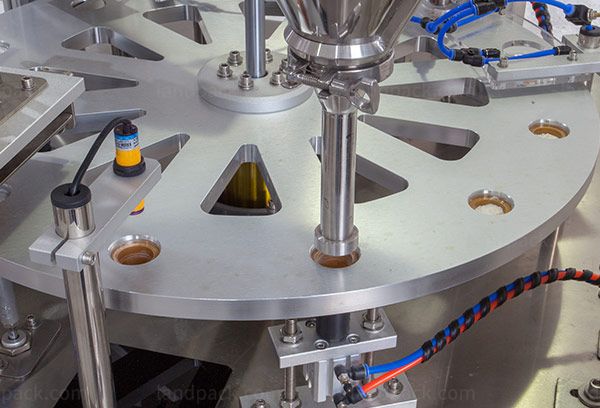

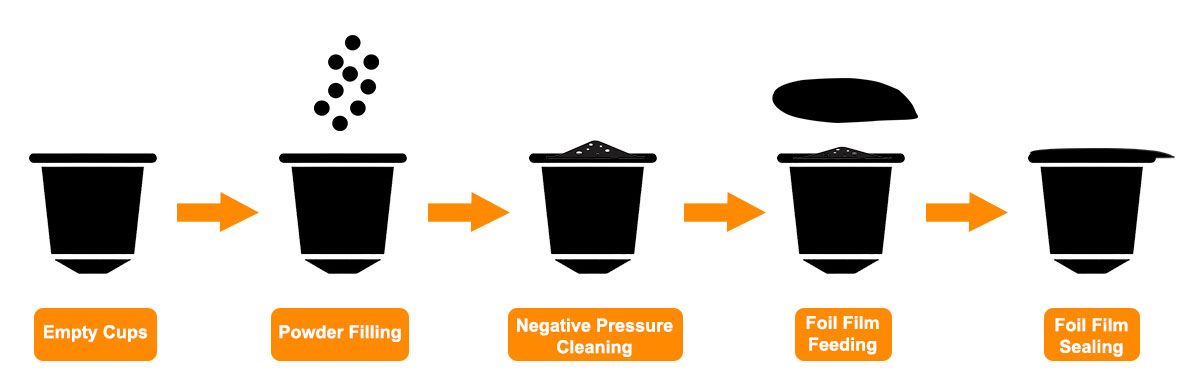

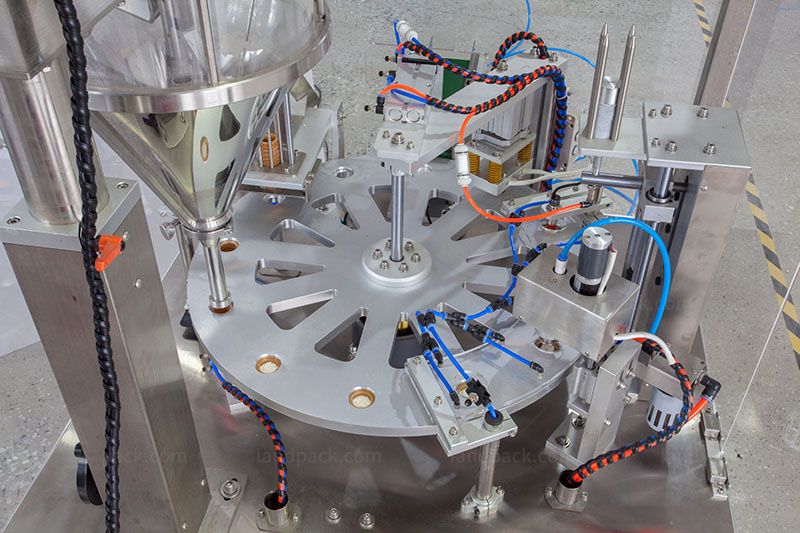

Process Workflow:

Automatic Capsule Feeding - Empty capsules are loaded into the machine hopper, then automatically conveyed and oriented into position for filling.

Coffee Dosing - A precisely calibrated auger filler dispenses the correct amount of ground coffee into each capsule.

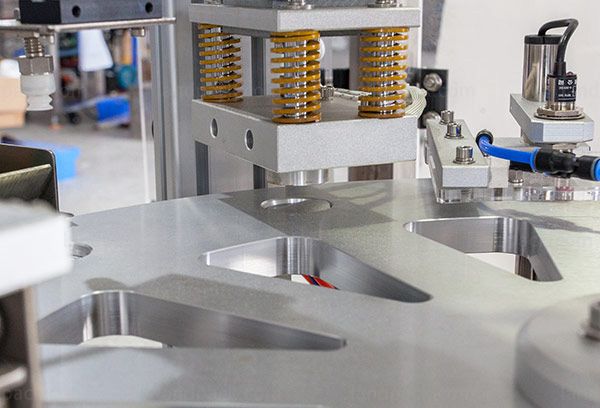

Tamping - After dosing, a tamping stage compresses the coffee within the capsule to ensure even density and optimal extraction.

Film Feeding - Pre-cut lid material is supplied, aligned, and positioned over the capsules.

Heat Sealing - The film or lid is heat-sealed to the capsule body using controlled temperature, pressure, and dwell time.

Finished Product Output - Once sealed, the capsules are discharged from the machine onto an output conveyor (or tray).

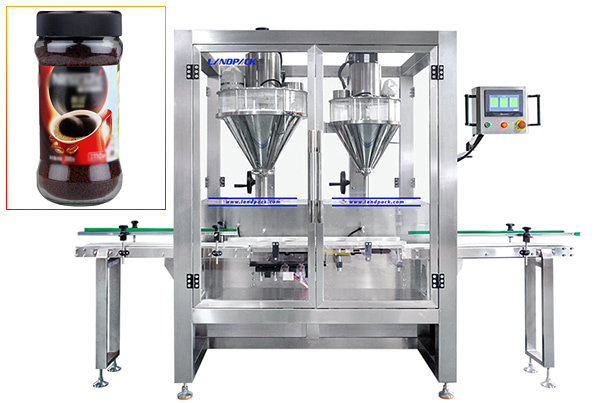

| Specification | |||||

Production Capacity | 800-1500cups/hour | ||||

| Measurement | Screw head filling (1 or 2 heads) | ||||

| Filling Range | 5-10g ( Can be customized ) | ||||

| Size (L) | 1500*(W)1200*(H) 1700mm | ||||

| Voltage | 220V,50/60HZ,2.2kw | ||||

| Weight | 500kg | ||||

| Air Supply | 1m/points, 0.6-0.75Mpa | ||||

| Structure | 304 stainless steel body | ||||

Machine Key Components:

* Hopper

* Filling Device

* Cup Drop Device

* Film Placing Device

* Heat Sealing Device

Air Supply System The machine is equipped with a high-quality Air Source Treatment Unit, also known as an FRL (Filter, Regulator, and Lubricator) assembly. |  |

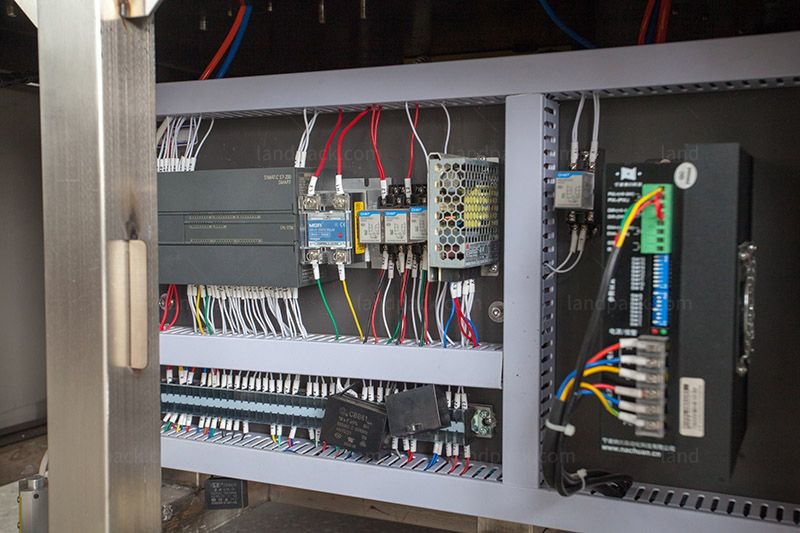

| Electrical Control Cabinet The machine is equipped with a fully enclosed electrical control cabinet designed for safety, stability, and ease of maintenance. |

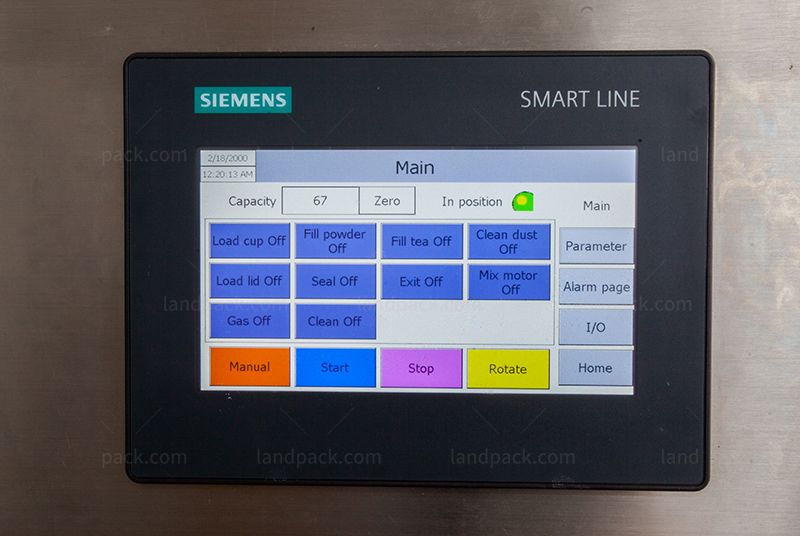

PLC + Touchscreen Control Panel The control system for managing speed, fill weight, temperature, sealing time, alarms, and other parameters. Allows operators to monitor and adjust. |  |

| Turntable System Many machines use a rotary table to cycle capsules through each of the modules (cup drop → filling → film/lid placement → sealing → output). This helps with compactness, smooth transitions, and higher speed. |

Get Price & More Detail