Laundry Fragrance Beads Filling Machine | Granule Filling and Sealing Machine

Model:

The rotary fragrance beads filling machine is designed for accurate, high-speed bottle filling of free-flowing granules. Equipped with a multihead weigher and rotary indexing system, it ensures stable dosing, smooth bottle handling, and continuous operation.

Application:

The system integrates feeding, weighing, rotary filling, and discharge, making it ideal for automated production lines in household and food industries.

Application:

The rotary fragrance beads filling machine is designed for accurate, high-speed bottle filling of free-flowing granules. Equipped with a multihead weigher and rotary indexing system, it ensures stable dosing, smooth bottle handling, and continuous operation. The system integrates feeding, weighing, rotary filling, and discharge, making it ideal for automated production lines in household and food industries.

Package Type:

This rotary filling system is widely used for filling granular products into plastic or PET bottles. Its multihead weighing unit provides precise portion control, while the rotary structure improves output efficiency and filling consistency.

Suitable Products:

This granule filling machine, equipped with a multi-head weigher, is designed for fast, accurate, and stable bottling of granular products. The machine is suitable for a variety of granular materials.

Fragrance & Air Fresheners: Such as ragrance beads, scented crystals, deodorizing granules.

Household & Cleaning Products: desiccants, detergent beads, water softener granules.

Food & Snack Items: Nuts, dry fruit, and other dry granular food products.

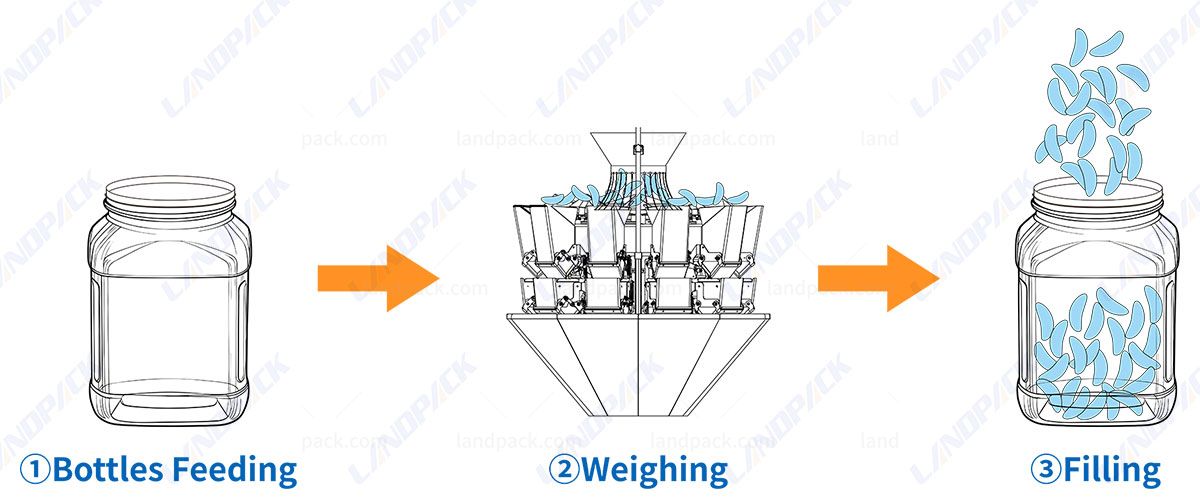

Workflow:

1. Bottle Feeding: Empty bottles are automatically sorted and transferred onto the turntable in preparation for filling.

2. Product Feeding and Measuring: Granular material is supplied to the multi-head weighing system for precise portion measurement.

3. Granule Filling: The weighed granules are accurately dispensed into each bottle.

4. Output: Once filled, the bottles are smoothly conveyed to the collection zone for capping or subsequent packaging steps.

| Multi-heads weigher | |||||

| Model | LD-14 | LD-16 | LD-12 | LD-10 | LD-8 |

| Number of weighing heads | 14 | 16 | 12 | 10 | 8 |

| Per weighing range | 10-2000g | 10-1000G | |||

| Weighing Accuracy | ±0.3-1.5g | ±0.3-1.5g | ±0.3-1.5g | ±0.3-1.5g | ±0.3-1.5g |

| Weighing Speed | 120bag/min | 180bag/min | 100bag/min | 70bag/min | 60bag/min |

| Hopper capacity | 1300ml | 1300ml | 1700ml | 1300ml | 1300ml |

| Hopper type | Double row unrecorded bucket | Double row unrecorded bucket | single row bucket | Double row unrecorded bucket | Double row unrecorded bucket |

| Product default mode | 99 modes | ||||

| Control element | 10.4-inch LCD aiming screen | ||||

| Accuracy weighing and filling | |

| Model | LF-ZP-10 |

| Output | 20-30 bottles/min |

| Bottle diameter | Φ30mm-Φ135mm (customizable) |

| Bottle height | 40mm-200mm (customizable) |

| Power | 750W,220V,50Hz |

| Weight | 200kg |

Machine Key Components:

1. Elevator

2. Multi-Head Weight Weigher

3. Filling Machine

Feature:

High-Speed, High-Capacity Filling System Engineered for high-throughput production of granular fragrance beads, this system supports continuous operation for medium- to large-scale batches. It minimizes process bottlenecks and maintains a steady, reliable material flow throughout production. |  |

| Precision Multi-Head Weighing for Accurate Dosing The multi-head weighing system delivers exceptional dosing accuracy, ensuring consistent net weights and uniform filling results—even when handling granules of varying sizes or shapes. |

Robust Stainless Steel Construction for Hygiene and Durability All components in contact with the product are manufactured from food-grade stainless steel, providing excellent corrosion resistance, hygienic performance, and long service life in demanding production environments. |  |

| Integrated Z-Type Feeding System for Seamless Material Flow A Z-type bucket conveyor supplies granules continuously to the weighing unit, supporting uninterrupted operation while reducing the need for manual refilling, boosting productivity, and saving labor time. |

Get Price & More Detail