Automatic Fragrance Beads Pouch Weighing and Packaging Machine

Model: LD-320AS

The LD-320AS Vertical Form-Fill-Seal machine integrates a 4-head linear weigh system to deliver high-precision, automatic bag forming, weighing, filling, and sealing in 4-side sealed pouches.

Application:

Typical Granule or Small Particle Products Suitable for LD-320AS Packaging, such as fragrance beads, flavour pearls, popcorn, candy, pet food, seeds, jerky, frozen food, chocolate, etc.

Application:

Designed to package a wide range of free-flowing granules and fine particles, the LD-320AS excels across food, chemical, and daily-use sectors.

Package Type:

4-side seal sachets produced from roll film, featuring flat, uniform edges and excellent sealing integrity. The LD-320AS supports small to medium-size pillow-free sachets with precise bag length control, making it suitable for single-serve and retail-ready packaging. Film options include laminated plastic, aluminum foil, and composite materials for moisture- and aroma-sensitive products.

Suitable Products:

The LD-320AS vertical packing machine with a 4-head linear weigher is engineered for accurate weighing, stable filling, and consistent 4-side sealing of free-flowing granules and fine particles. It is suitable for packaging a wide range of products, including:

Home care products: laundry fragrance beads, scent boosters, wardrobe freshener granules, deodorizing beads, and air-freshener pellets.

Daily chemical products: laundry powder, detergent granules, bath beads, cleaning additive particles, scented crystals, and washing enhancers.

Other granular materials: snacks, small candies, food seasoning granules, silica gel, desiccant beads, and other free-flowing pellets.

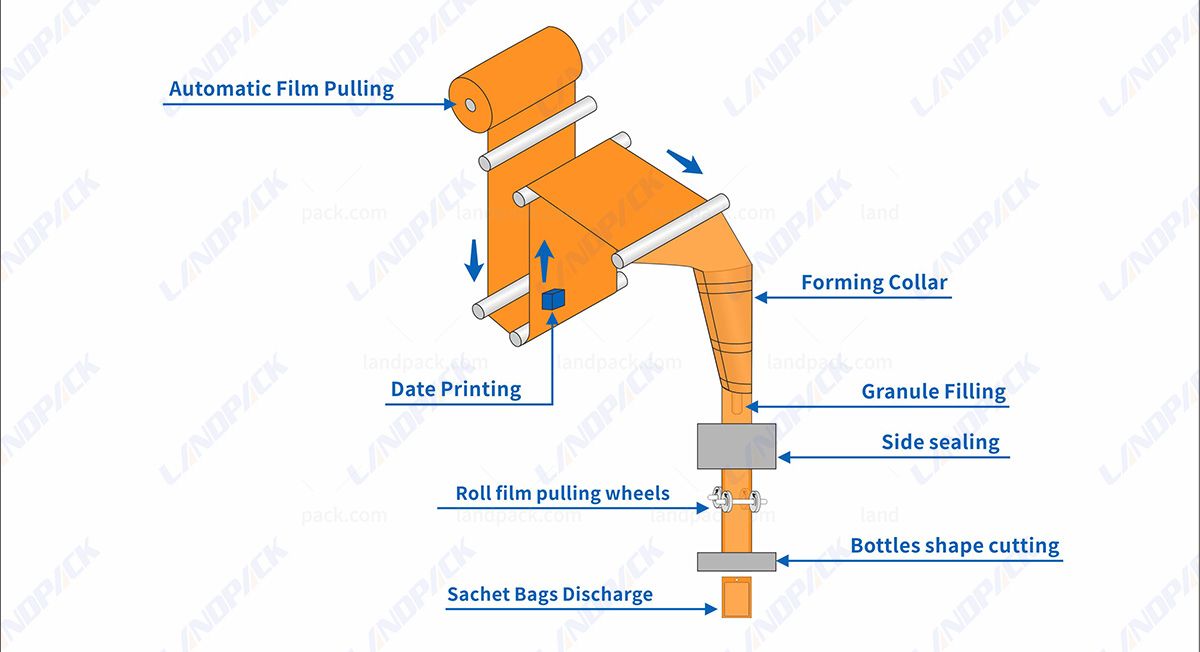

Workflow:

1. Material Feeding: The fragrance beads are fed into the machine via a linear weigher for accurate measurement.

2. Bag Forming: Film is pulled and shaped into a pouch, ready for filling.

3. Filling: Measured beads are automatically dispensed into each pouch

4. Sealing: The pouch is heat-sealed to ensure a firm, leak-proof closure.

5. Cutting & Discharge: Sealed pouches are cut to size and delivered to the collection platform for packing or further processing.

| Model | LD-320A | LD-380A |

| Film width | 120-320mm | 180-380mm |

| Bag length | 50-200mm | 60-280mm |

| Bag width | 50-150mm | 60-180mm |

| Diameter of film roll | Max.300mm | Max.320mm |

| Packing speed | 35-70bag/min | |

| Measuring range | 50-500ml | 50-750ml |

| Film thickness | 0.04-0.07mm | |

| Power | 220V 50/60Hz 2.2KW | 220V 50/60Hz 2.5KW |

| Machine size(L*W*H) | 970*680*1950mm | 1100*800*2150mm |

| Machine weight | About 300kg | About 450kg |

Machine Key Components:

1. 4 heads weigher

2. Film Rolling Device

3. Control Panel

4. Packing Machine

5. Z Type MaterialConveyor

6. Finished Product Conveyor

Feature:

4 Heads Linear Weigher Ensures precise and consistent portioning for each pouch, maintaining high accuracy for delicate items like scented beads or granules. |  |

| Film Rolling Device Ensures stable film unwinding and uninterrupted pouch forming, enabling efficient processing of multiple bag sizes and styles. |

Control Panel Features a user-friendly PLC touch-screen interface for simple operation, real-time status monitoring, and fast parameter adjustments to enhance productivity. |  |

| Packing Machine Combines forming, filling, sealing, and cutting into a single automated workflow, boosting output efficiency while minimizing manual labor. |

Z Type Material Conveyor Automatically conveys product to the weighing unit to maintain uninterrupted operation while minimizing manual intervention. |  |

| Finished Product Conveyor Gently moves completed, filled, and sealed pouches to the collection zone, preparing them for subsequent packing processes. |

Get Price & More Detail