Automatic Air Freshener Beads Filling Machine with High Speed Capping Machine

Model: Automatic Air Freshener Beads Filling Line

This fragrance beads granule filling line is designed for accurate bottle filling and high-speed capping of free-flowing granular products.

Application:

The granule filling and capping line is widely used in home care, food, and pet product industries that require precise dosing and secure bottle closure.

Application:

It is suitable for medium- to high-output production environments, reducing manual handling while ensuring uniform fill levels and reliable cap sealing. The line supports flexible bottle formats and maintains stable operation during long production runs.

Package Type:

Suitable for rigid containers such as plastic bottles, jars, and canisters. The line supports round, square, and custom-shaped bottles with screw caps or flip-top caps, making it ideal for packaging granular products in various bottle sizes used in home care, food, pet, and industrial applications.

Suitable Products:

This granule filling line, consisting of a bottle unscrambler, multi-head weigher, granule filling machine, vibration cap feeder, and automatic capping machine, is designed for efficient and accurate bottling of free-flowing granular materials. While mainly applied to fragrance beads, it is also suitable for a broad range of products, including:

Home Care Products: laundry scent beads, fragrance boosters, washing powder granules, wardrobe freshener granules, deodorizing beads, and air-freshener pellets.

Food & Nutrition Items: candy beads, sugar pearls, seasoning granules, snack particles, nuts, dried fruit pieces, and dietary supplement granules.

Industrial & Agricultural Products: silica gel, desiccant beads, fertilizer pellets, seeds, plastic pellets, and specialty chemical granules.

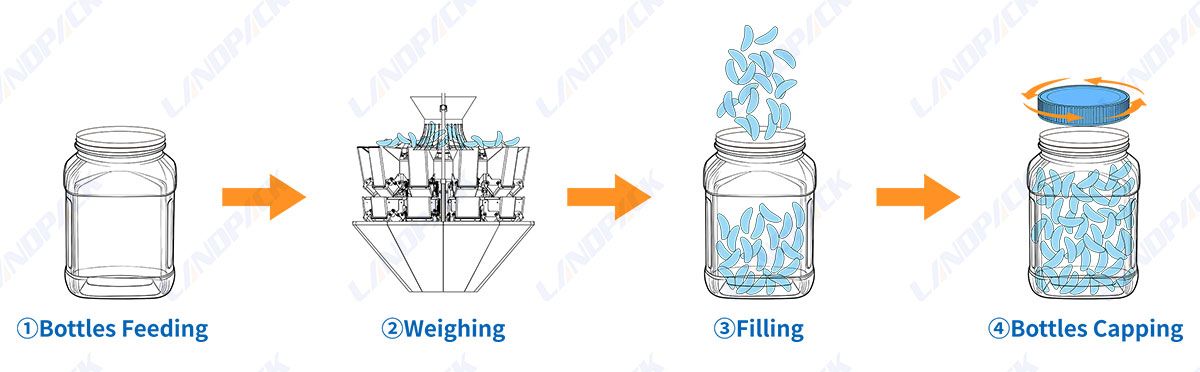

Workflow:

1. Bottle Unscrambling: Empty bottles are automatically sorted, oriented, and conveyed into the production line by the bottle unscrambler.

2. Granule Weighing: The multi-head weigher precisely measures the preset quantity of fragrance beads or other free-flowing granular materials.

3. Granule Filling: Weighed granules are smoothly transferred into each bottle through the filling unit, ensuring clean filling and minimal material loss.

4. Cap Feeding: Caps are correctly oriented and continuously supplied by the vibrating bowl feeder to maintain stable production speed.

5. Automatic Capping: The high-speed capping machine applies uniform torque to securely fasten caps onto the bottles.

6. Finished Product Collection: Capped bottles are conveyed to the output table, ready for labeling, packing, or further downstream processing.

| Multi- heads granules weighing double heads rotary filling machine | ||

| Model | LD-GZJ200M-R(double turntable filling) | LD-GZJ100M-R(Single turntable filling) |

| Material | 304# Stainless steel | 304# Stainless steel |

| Filling diameter | φ40 -φ130mm | φ40 -φ130mm |

| Applicable height | 50-200mm (customized according to Bottle size) | 50-200mm (customized according to Bottle size) |

| Filling speed | 30-50 cans per minute | 10-20 cans per minute |

| Air source | 0.6-0.8Mpa | 0.3-0.5Mpa |

| Voltage | 220V,50HZ | 220V,50HZ |

| Power | 2.5KW | 1.5KW |

| N.W./G.W. | 200/320KGS | 100/220KGS |

| Size | 2000*1000*1400mm | 2000*500*1400 |

| High speed capping machine | ||

| Model | LFX-GS-150(Eight wheel capping) | LFX-GS-250(Six wheel capping) |

| Capacity | 40-100Bottles/min | 30-80Bottles/min |

| Bottle cap diameter | Φ18mm-Φ80mm(Could be customized) | Φ18mm-Φ80mm(Could be customized) |

| Bottle diameter | Φ35mm-Φ140mm(Could be customized) | Φ35mm-Φ140mm(Could be customized) |

| Bottle sealing height | 38mm-300mm(Could be customized) | 38mm-300mm(Could be customized) |

| Power | 2KW | 1.5KW |

| Voltage | 220V、50HZ | 220V、50HZ |

| Air pressure | 0.6-0.8Mpa | 0.5-0.7Mpa |

| Weight | 350kg | 300kg |

| Dimensions | H3120*W1544*L2122 | H3100*W1244*L2122 |

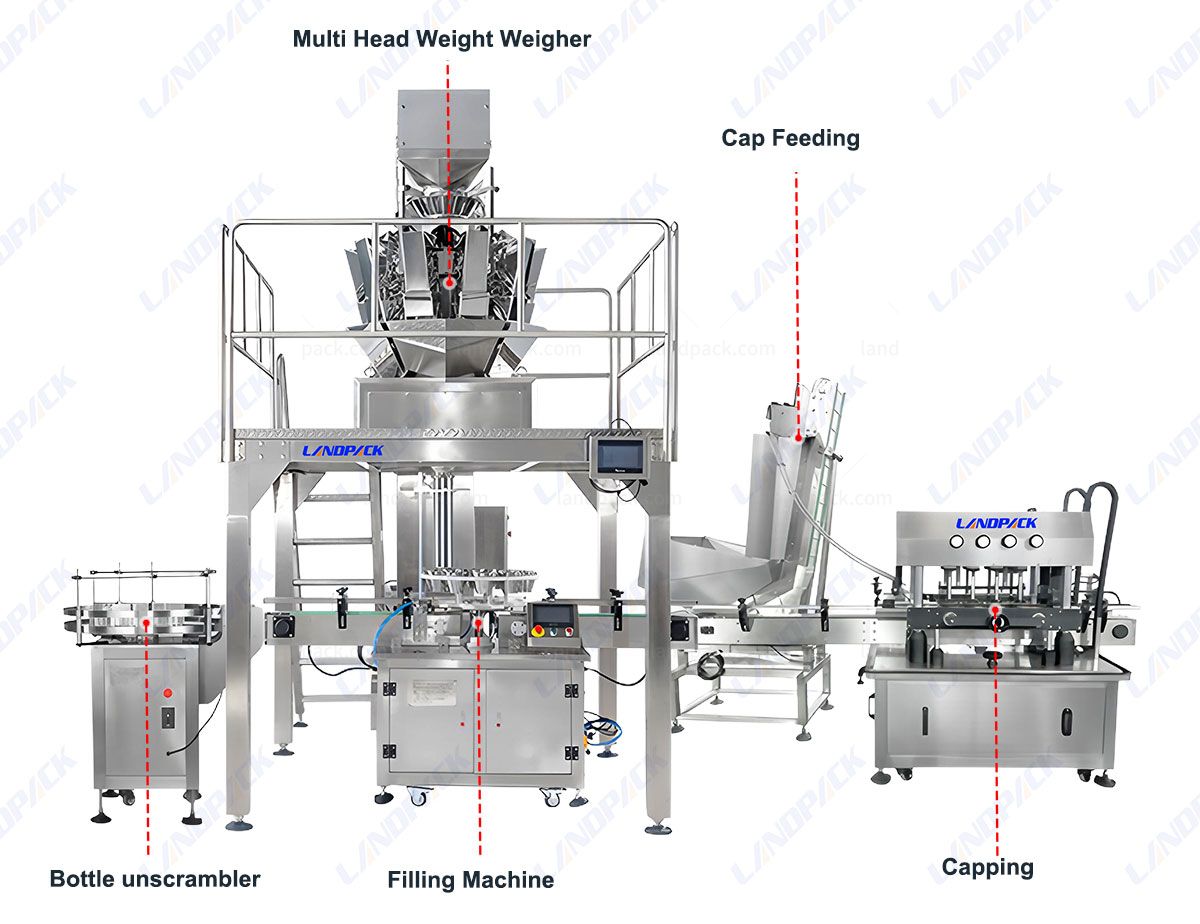

Machine Key Components:

1. Bottle Unscrambler

2. Multi Head Weight Weigher

3. Filling Machine

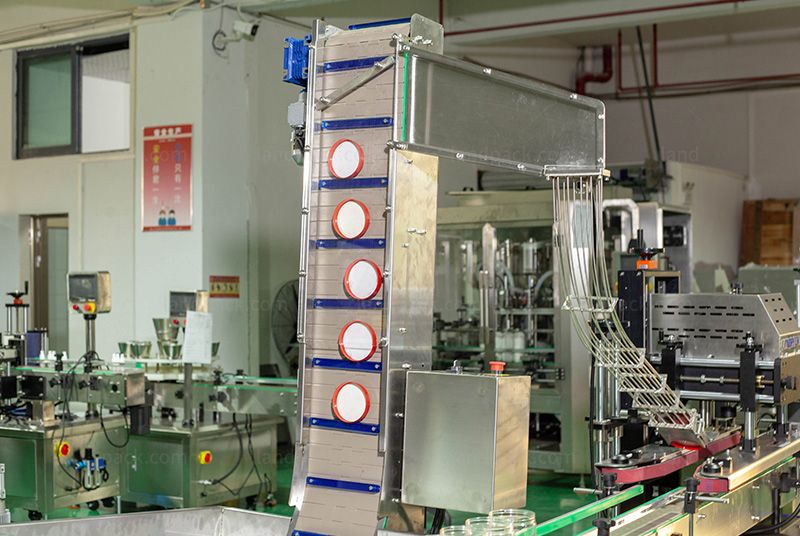

4. Cap Feeding

5. High Speed Capping Machine

Feature:

Bottle Unscrambler Automatically arranges and feeds empty bottles into the line, ensuring stable, continuous infeed and reducing manual handling. |  |

| Multi-Head Weigher Provides fast and accurate weighing of granular materials, improving filling precision and reducing product giveaway. |

Filling Machine Delivers controlled, clean filling into bottles with stable positioning and minimal spillage. |  |

| Cap Feeding System Automatically orients and supplies caps to the capping station, supporting uninterrupted high-speed operation. |

High-Speed Capping Machine Applies caps quickly and securely with consistent torque, ensuring reliable sealing and uniform finished products. |  |

Get Price & More Detail