Dry Fruit Packing Machine | Automatic Raisin Vffs Packaging Machine

Model: LD-520A

This vertical packaging system uses a 14-head 2.5L patterned multihead weigher with a Z-type elevator and finished product conveyor for high-accuracy, high-speed nut and dry fruit packing.

Application:

Designed for processors of dried fruit, nuts, seeds, grains, sugar, and other small particulate materials, this automated packaging line excels at accurate portioning and sealed pouches for retail markets.

Application:

This vertical packaging system uses a 14-head 2.5L patterned multihead weigher with a Z-type elevator and finished product conveyor for high-accuracy, high-speed nut and dry fruit packing. Designed for processors of dried fruit, nuts, seeds, popcorn, jerky, salt, grains, sugar, and other small particulate materials, this automated packaging line excels at accurate portioning and sealed pouches for retail markets.

Package Type:

Supported bag types include: pillow bags, back sealing bags, 3/4 sided seal bags. Suitable for laminated packaging films such as PET/PE, OPP/CPP, and other heat-sealable materials.

Suitable Products:

This vertical form-fill-seal packaging machine is engineered for free-flowing and semi-free-flowing granular products that require fast, accurate multihead weighing. With a 14-head 2.5L patterned weigher and stable material conveying system, it handles irregular shapes and mixed sizes efficiently, making it suitable for continuous, high-volume food production lines.

Suitable materials include:

Dried Fruits: Raisins, dried mango cubes, dried pineapple, dried berries

Grains & Beans: Rice, oats, lentils, chickpeas, mung beans, mixed grains

Dry Granular Foods: Breakfast cereals, pet food kibbles, sugar, salt, snack pellets

Workflow:

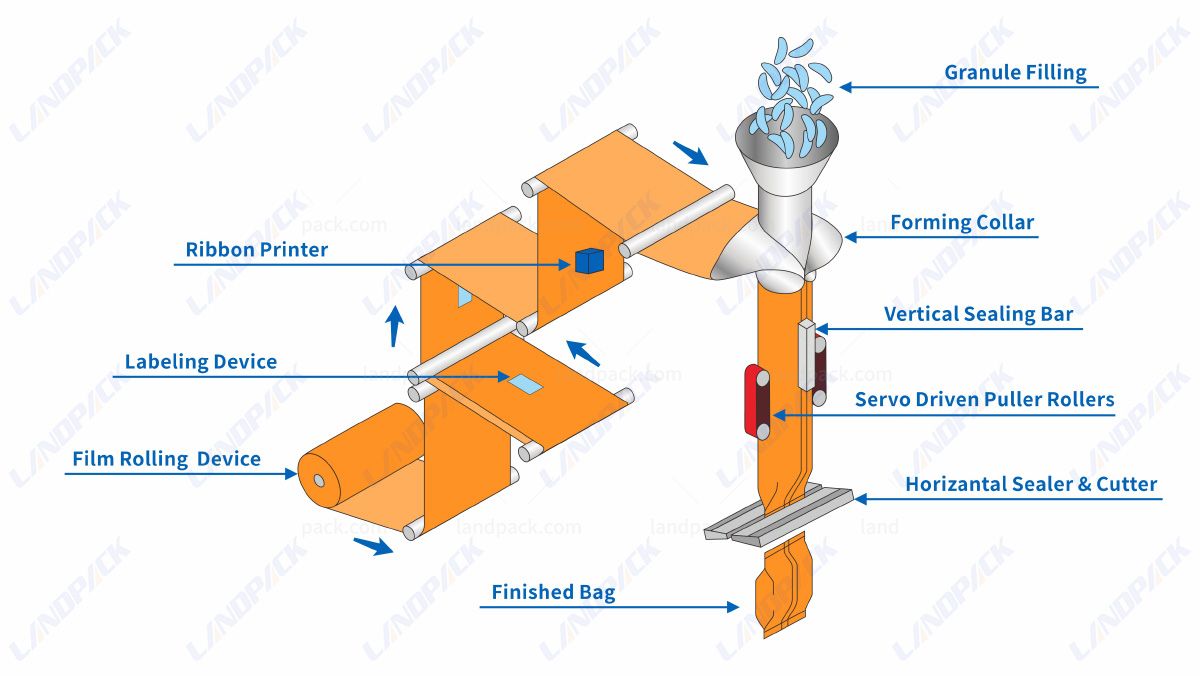

1. Film Unwinding: The Packaging film is released smoothly from the film rolling device.

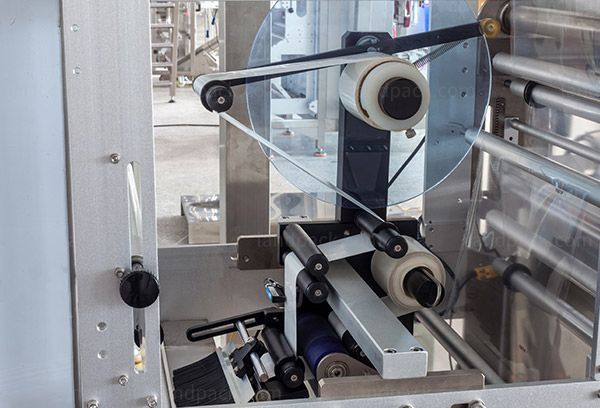

2. Printing & Labeling: Date/lot code is printed by the ribbon printer, while labels can be applied inline if required.

3. Bag Forming: Film passes through the forming collar to shape a vertical pillow bag.

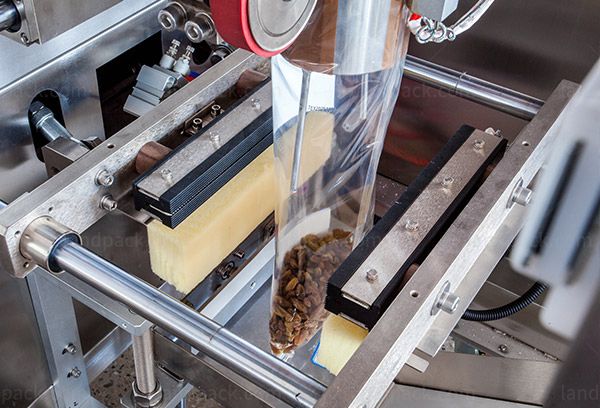

4. Granule Filling: Granule products are accurately filled into the formed bag from the filling system.

5. Vertical Sealing: The vertical sealing bar creates a strong back seal.

6. Film Pulling: Servo-driven puller rollers ensure stable film movement and precise bag length.

7. Horizontal Sealing & Cutting: Top and bottom seals are made, and bags are cut individually.

8. Finished Bag Output: Completed bags are discharged smoothly for the next process.

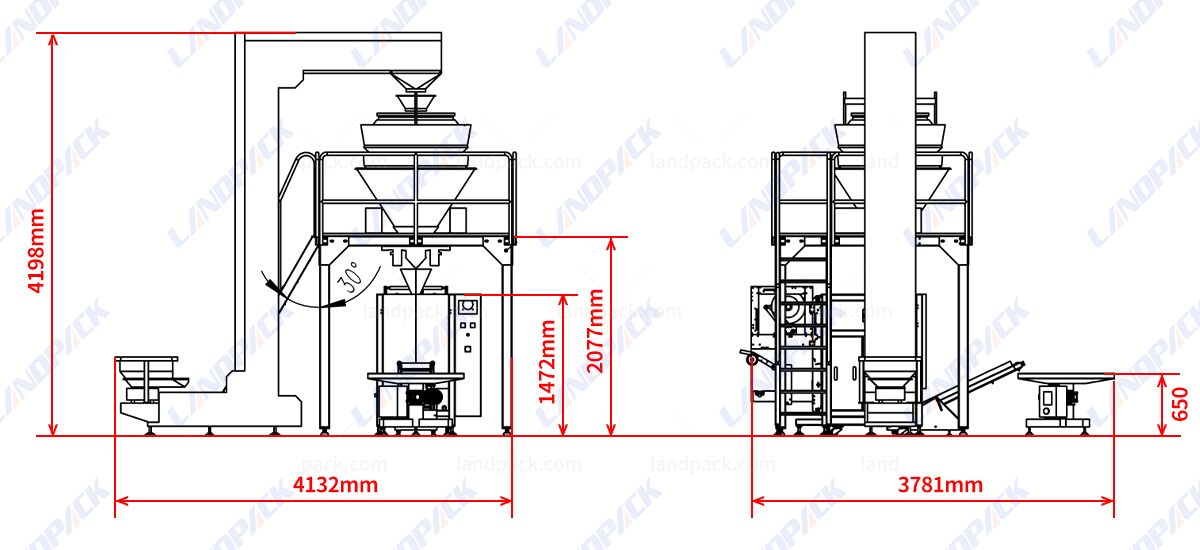

| Model | LD-420A | LD-520A | LD-620A | LD-720A |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 60-400mm | 60-450mm | 60-500mm |

| Bag Width | 60-200mm | 100-250mm | 65-300mm | 65-350mm |

| Film Roll Diameter | Max.600mm | Max.600mm | Max.600mm | Max.600mm |

| Pakaging Rate | 5-60 bags/min | 5-40 bags/min | 5-35 bags/min | 5-30 bags/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.620mm | 150-Max.720mm |

| Making bag volume | 1000ml | 2000ml | 3000ml | 5000ml |

| Power Supply | 220V, 50/60HZ, 3KW | 220V, 50/60HZ, 3KW | 220V, 50/60HZ, 3.2KW | 220V, 50/60HZ, 3.5KW |

| Machine Size | 1217*1015*1343 mm(L*W*H) | 1488*1080*1490 mm(L*W*H) | 1488*1180*1550 mm(L*W*H) | 1780*1350*2050 mm(L*W*H) |

Machine Key Components:

1. Z Type Elevator

2. Multi-head Electrical Weigher

3. Support Platform

4. Form Structure

5. Labeling Machine

6. Vertical Packing Machine

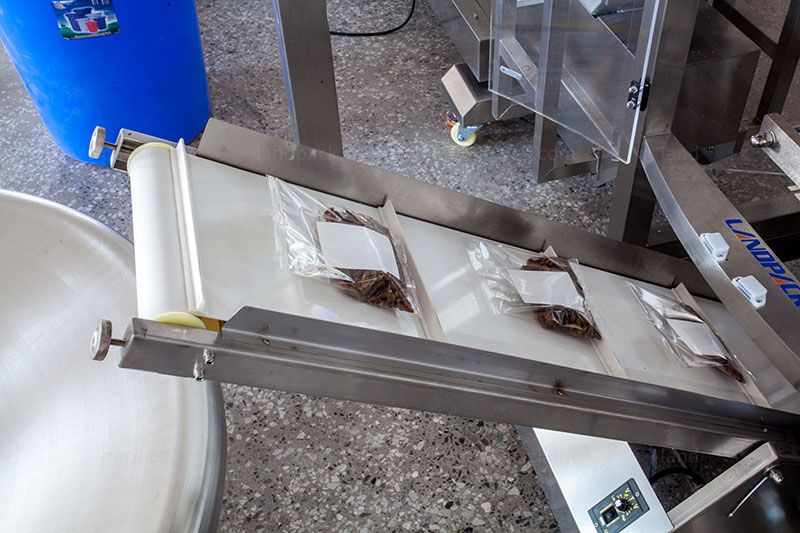

7. Finished Bag Conveyor

8. Round Table for Collection

Feature:

Z Type Elevator Gently conveys raisins and dried fruits to the weighing unit with a steady flow, reducing product damage and ensuring uninterrupted feeding. |  |

| Multi-head Electrical Weigher Delivers fast and precise weighing performance, making it ideal for free-flowing dried fruits while improving pack weight consistency and minimizing overfill. |

Labeling Machine Automatically applies labels during the packaging process, supporting branding, product traceability, and regulatory requirements without impacting line speed. |  |

| Vertical Packing Machine (VFFS) Integrates bag forming, filling, and sealing into a single compact system, providing reliable operation, clean bag presentation, and efficient production for dried fruit packaging. |

Finished Bag Conveyor Smoothly discharges finished bags to the downstream conveyor, preventing congestion and enabling continuous, hands-free operation. |  |

| Round Table for Collection Neatly collects completed packages, simplifying manual handling or secondary packaging steps and improving overall efficiency. |

Get Price & More Detail