Automatic Flour Sachet Packaging Machine

Model: LDFS-960D

High-efficiency powder sachet packaging machine for food, beverage, and pharma industries. Supports 3/4-side seal sachets, up to 35 bags/min/lane.

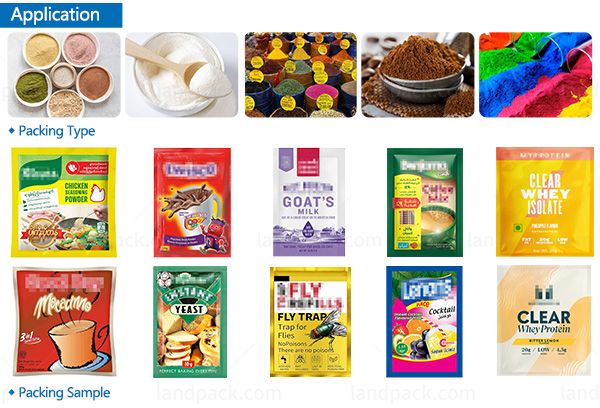

Application:

It is ideal for packaging products such as milk powder, coffee powder, protein powder, cocoa powder, instant drink mixes, seasoning powder, chili powder, spice blends, flour, starch, pharmaceutical powder, detergent powder, and cosmetic powder.

What is a Flour Sachet Packaging Machine?

It accurately measures and fills each portion, seals the package securely, and ensures consistent weight and appearance. This machine is commonly used in food production lines for single-use or retail packaging.

Package Type:

The multi lane packing machine was specifically created for high-speed production of small sachets, accommodating different pouch styles for optimal product and market adaptation.

Suitable Products:

Landpack multi-lane powder packing machine was specifically created to offer efficient packaging of multiple powder products used across industries such as health, food and chemical.

* Food Powder: Suitable for kinds of beverages and food powders, such as flour, milk powder, coffee powder, cocoa powder, seasoning powder, baking powder, spice, and more.

* Nutrition & Health Powder: Widely used in the fitness and nutritional supplement industries for collagen powder, protein powder, vitamin powder and mineral supplement powders that provide exact control of portions for customer comfort.

* Other Industrial Applications: Also suitable for non-food powders including herbal powder, chemical agents powder, prescription powder, detergent powder, and washing powder, offering flexible solutions for both pharmaceutical and industrial packaging needs.

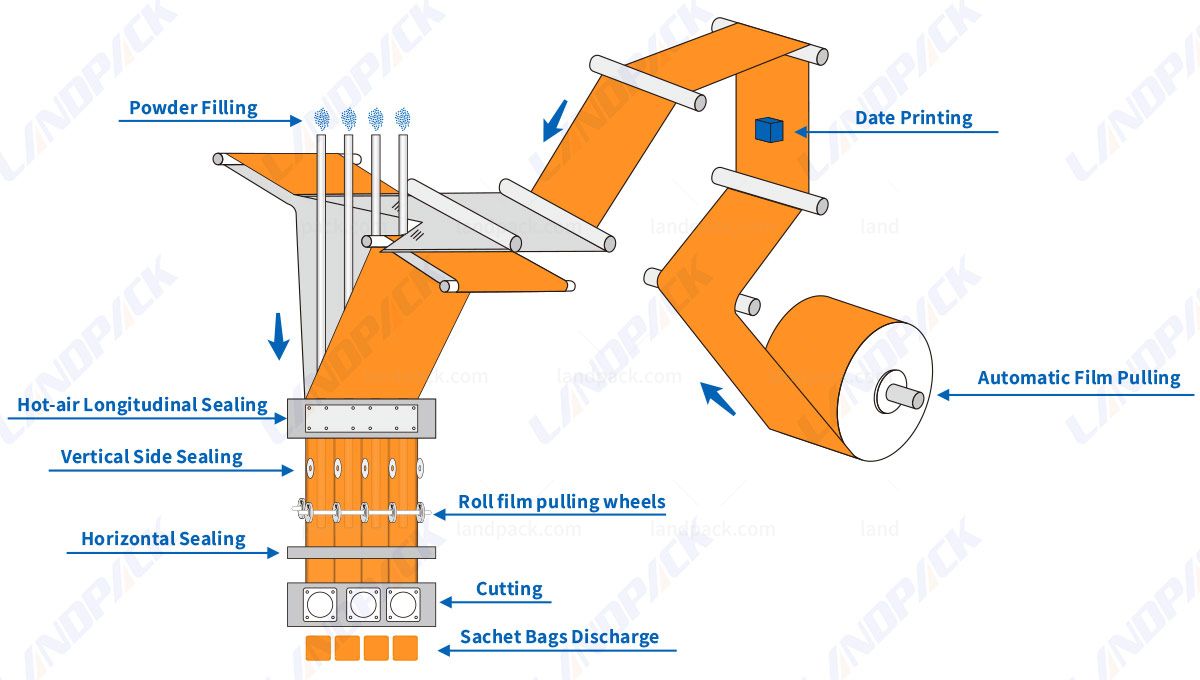

Process Workflow:

This multi-lane sachet packaging machine is designed for efficient packaging of powders used in beverages, food, pharmaceuticals, and related industries. The process works as follows:

Automatic Film Feeding: The film roll is smoothly drawn into the machine for steady, uninterrupted operation.

Date Coding: A printer imprints essential details such as production date, batch code, or expiry information on each sachet.

Film Traction Rollers: The film moves through traction rollers that maintain optimal tension and perfect alignment for uniform bag formation.

Powder Dispensing: Precisely measured powder is filled into each lane through dosing devices, ensuring consistent weight accuracy.

Longitudinal Heat Sealing: Hot air seals the vertical edges of the film to shape the sachet body securely.

Side Sealing: The sachet sides are firmly bonded to prevent leakage and ensure a neat finish.

Cross Sealing: The upper and lower edges of the sachets are sealed to form completely enclosed pouches.

Cutting: The continuous strip of sachets is cleanly separated into individual packs with high precision.

Discharge: Finished sachets are automatically released from the machine, ready for collection, cartoning, or further packaging.

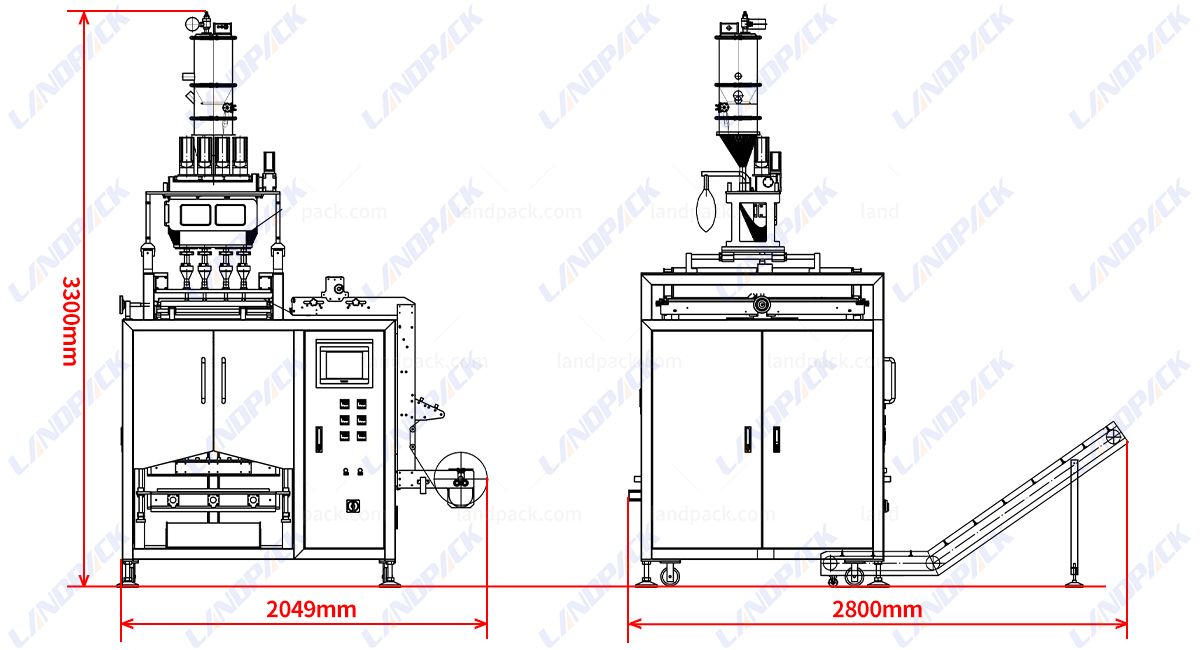

| Model | LD-280BF | LD-560BF |

| Lane number | 4-6 Line | 8-12 Line |

| Filling Method | Auger filling by servo motor | |

| Capacity | Max.35 cycles/min | |

| Sachat Size | L: 50-180mm; W: 17-30mm | L: 50-180mm; W: 17-30mm |

| Film Width & Thickness | Max.280mm, 0.07-0.10mm | Max.560mm, 0.07-0.10mm |

| Sealing type | Back sealing/Stick bag | Back sealing/Stick bag |

| Cutting type | 1. Straight cutting; 2. Zig-zag cutting; 3. Round cutting; 4. Irregular | |

| Air & Powder | 0.8Mpa 0.8m3/min; 3.5kw | 0.8Mpa 0.8m3/min; 5.5kw |

| Dimension & weight | 1385*918*2005mm; 350kg | 1685*1300*2005mm; 550kg |

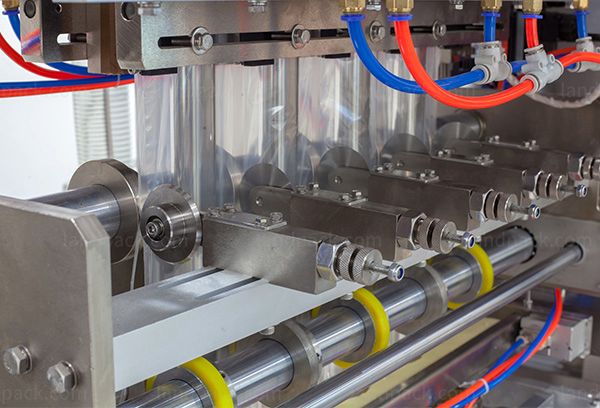

Machine Key Components:

1. Vacuum Feeder

2. Motor

3. Feeding Hopper

4. Auger Screws Measuring

5. Control Panel

6. Roll Film

7. Forming Structure

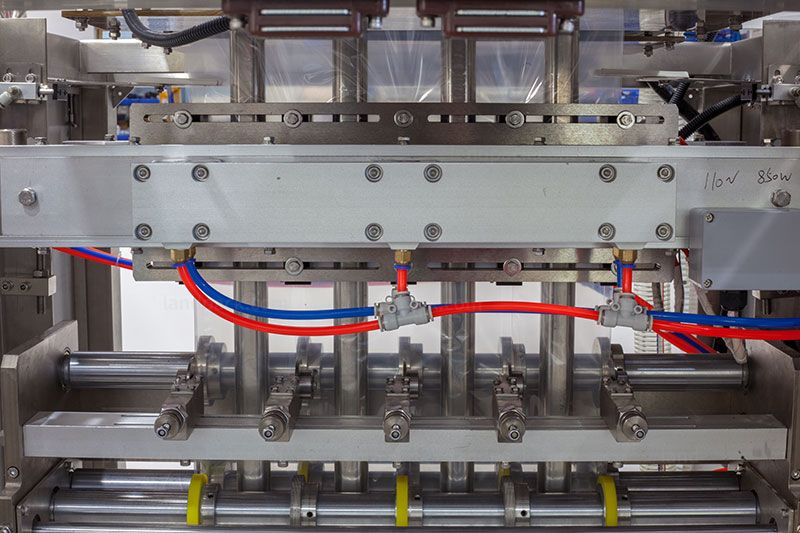

8. Vibration and Anti-static

9. Sealing and Cutting

Vacuum Feeder Automatically transfers dust from containers in bulk into the hopper, thus reducing the manual work, eliminating dust and ensuring a clean and continuous food supply. |  |

| Motor Equipped with a high-performance and stable motor that can drive the machine with constant speed and powerful power. This ensures the smooth and stable performance. |

Feeding Hopper Holds the powder material and provides a buffer for continuous production. Designed with easy cleaning access to maintain hygiene and prevent residue buildup. |  |

| Auger Screws Measuring High-precision auger dosing systems ensure precise filling of different powder densities, increasing the consistency of the product and reducing material waste. |

Control Panel Touch screen user-friendly that comes with PLC control makes it easy to perform parameter settings with real-time monitoring as well as rapid adjustments without having to stop the machine. |  |

| Roll Film Supports various laminated films to create 3-side, 4-side, or stick sachets. Stable film pulling ensures neat sealing and beautiful sachet appearance. |

Forming Structure Precisely shapes the film into sachets with accurate alignment and consistent pouch size, ensuring professional packaging quality. |  |

| Vibration and Anti-static Vibration helps powder settle evenly into sachets, while the anti-static device prevents powder from sticking to the film, improving filling accuracy and seal quality. |

Sealing and Cutting Multi-stage sealing (vertical and horizontal) ensures strong airtight seals, followed by precise cutting for clean edges and high-speed output. |  |

Get Price & More Detail