Flour Packing Machine | Automatic Vertical Form Fill Seal Machine

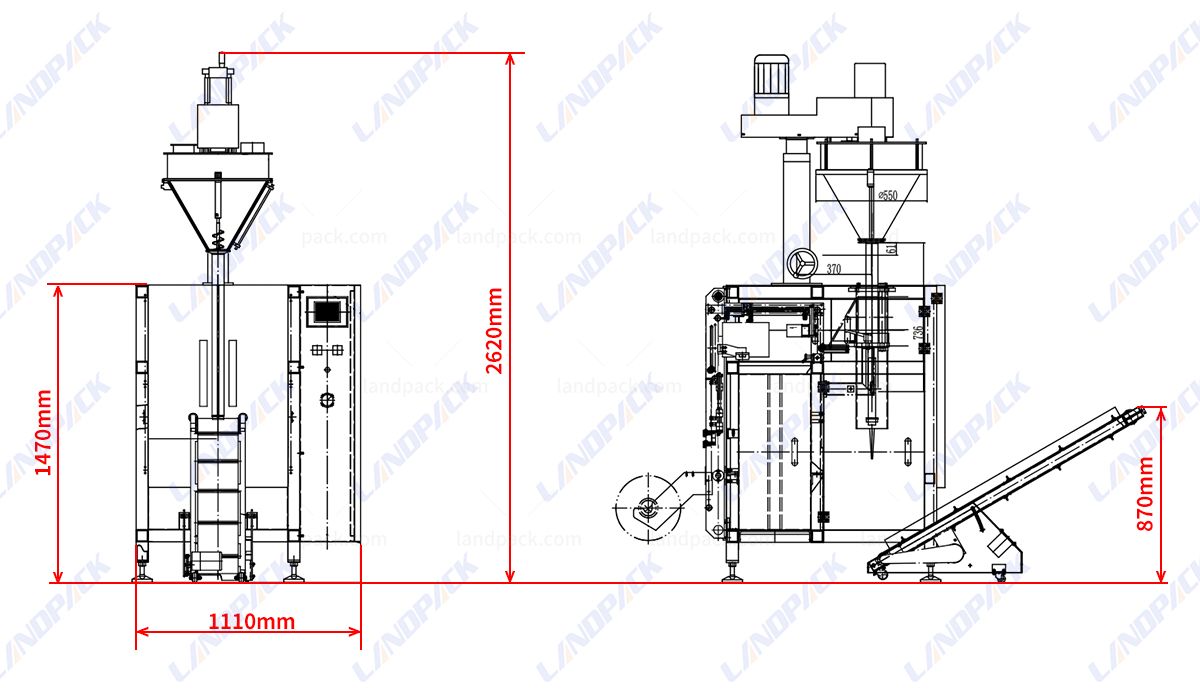

Model: LD-520D

This vertical form-fill-seal line features an integrated screw elevator (auger conveyor) that lifts powder into a high-precision auger filler, enabling continuous, automated feeding.

Application:

This machine is suitable for a broad variety of powdered products: food powders like flour and protein powder, nutritional or supplement powders, and even household chemical powders such as laundry detergent.

Application:

This machine is suitable for a broad variety of powdered products: food powders like flour and protein powder, nutritional or supplement powders, and even household chemical powders such as laundry detergent.

Package Type:

This vertical powder packing machine is suitable for forming and sealing a wide range of roll-film pouch styles, including back-seal (center-seal) bags, pillow bags, gusseted bags, and optional hole-punch or easy-tear designs.

Suitable Products:

This vertical powder packaging machine is engineered to handle a wide range of fine and free-flowing powders, making it suitable for various industries and product types.

Food & Beverage Powders: Flour, starch, protein powder, milk powder, cocoa powder, instant beverage mixes, seasoning powders.

Nutritional & Supplement Powders: Meal replacement powders, collagen powder, vitamin blends, herbal powder extracts, functional nutrition powders.

Household & Industrial Powders: Laundry detergent, dishwashing powder, cleaning agents, chemical additives, fine industrial powders.

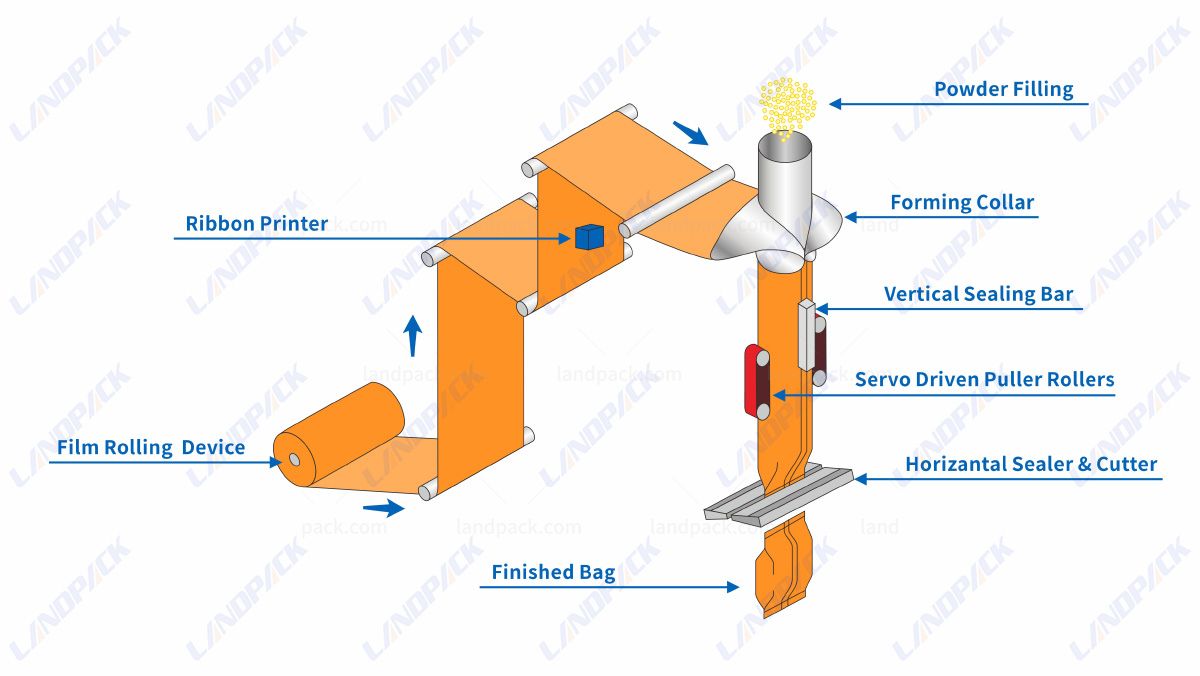

Workflow:

1. Film Rolling Device – Securely supports the film roll and feeds it smoothly to maintain uninterrupted operation.

2. Ribbon Printer – Marks production dates, batch codes, or simple graphics on the film before it is formed into a pouch.

3. Powder Filling – The auger filler accurately portions and delivers powder into the forming tube with consistent precision.

4. Forming Collar – Guides the film into a tube shape, preparing it for sealing and filling.

5. Vertical Sealing Bar – Produces the center seal along the back of the bag, ensuring structural integrity.

6. Servo Driven Puller Rollers – Precisely draw the film downward, guaranteeing uniform bag length and stable performance.

7. Horizontal Sealer & Cutter – Simultaneously closes the top and bottom seals and separates bags into individual pieces.

8. Finished Bag – Completed pouches are released in order, ready for quality checks or downstream packing.

| Model | LD-420D | LD-520D | LD-620D | LD-720D |

| Film Thickness | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm | 0.04-0.12mm |

| Bag Length | 80-300mm | 60-400mm | 60-450mm | 60-500mm |

| Bag Width | 60-200mm | 100-250mm | 65-300mm | 65-350mm |

| Film Roll Diameter | Max.600mm | Max.600mm | Max.600mm | Max.600mm |

| Packaging Rate | 5-60 bags/min | 5-40 bags/min | 5-35 bags/min | 5-30bag/min |

| Film Width | Max.420mm | Max.520mm | 150-Max.620mm | 150-Max.720mm |

| Making bag volume | 1000ml | 2000ml | 3000ml | 5000ml |

| Power Supply | 220V, 50/60HZ, 3KW | 220V, 50/60HZ, 3KW | 220V, 50/60HZ, 3.2KW | 220V, 50/60HZ, 3.5KW |

| Machine Size | 1217*1015*1343 mm(L*W*H) | 1488*1080*1490 mm(L*W*H) | 1488*1180*1550 mm(L*W*H) | 1780*1350*2050 mm(L*W*H) |

Machine Key Components:

1. Auger Screws Feeding Conveyor

2. Screw Metering

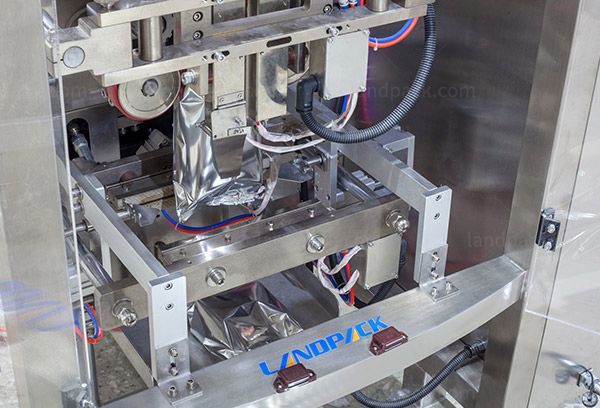

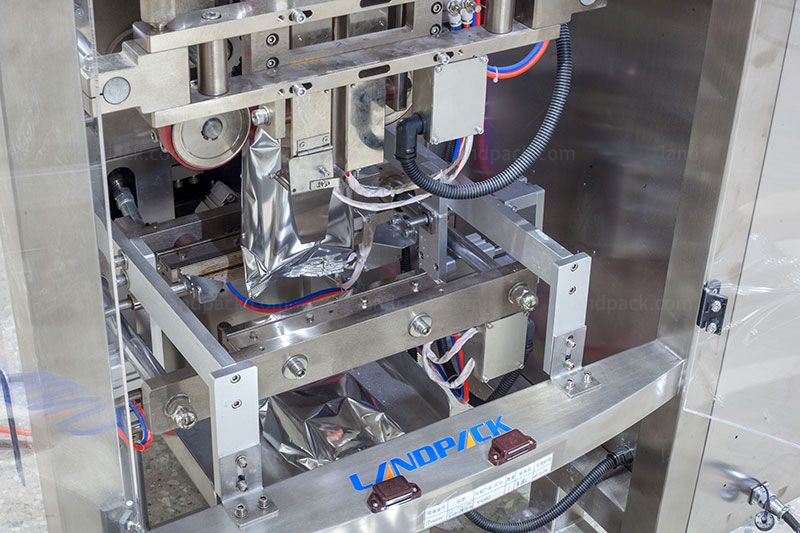

3. Form Structure

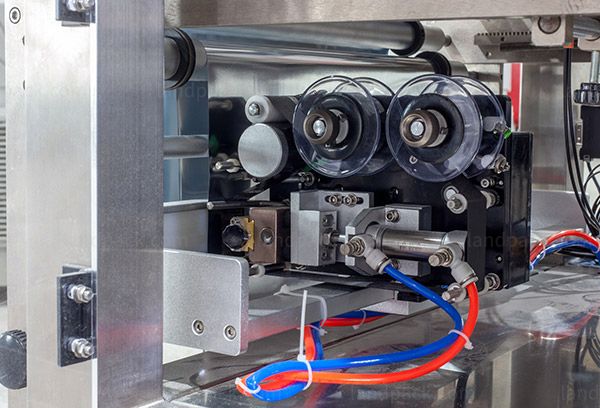

4. Sealing Structure

5. Sealing Structure

6. Finished Product Conveyor

Feature:

Auger Screws Feeding Conveyor Effectively transfers flour from the container to the metering device that is dust-free and stable which ensures clean and continuous production. |  |

| Screw Metering High-precision auger dosing device designed specifically for flour and fine powder that provides precise weight control as well as consistent bag-to-bag filling. |

Form Structure Automatically forms the film into the proper bag size with smooth and tight film tracking, allowing for various bag types as well as clean seams. |  |

| Sealing Structure Horizontal and vertical sealing devices ensure solid airtight seals, even for powders that are dusty which improves the integrity of packages and shelf longevity. |

Finished Product Conveyor The bag is gently removed of the machine to allow for easy cleaning, inspection or for direct connecting to the downstream packaging systems. |  |

Get Price & More Detail