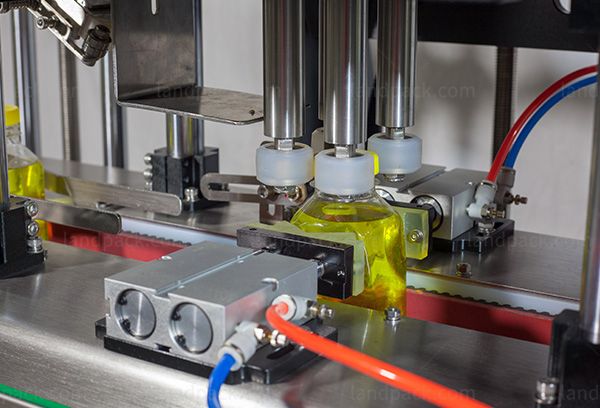

Automatic Fruit Juice Bottle Filling Capping Machine With Laser Printer

Model : LD-ALF-01

Application :

This bottle filling machine is perfect for efficiently and securely packaging various liquids and semi-liquids, including fruit juice, honey, tomato sauce, peanut butter, fruit jam, butter, olive oil, shampoo, body wash, chocolate paste, liquid detergent, and dishwashing liquid. It ensures precise filling and leak-proof sealing, making it an excellent choice for the food and personal care industries.

Application:

This bottle filling machine is perfect for efficiently and securely packaging various liquids and semi-liquids, including fruit juice, honey, tomato sauce, peanut butter, fruit jam, butter, olive oil, shampoo, body wash, chocolate paste, liquid detergent, and dishwashing liquid. It ensures precise filling and leak-proof sealing, making it an excellent choice for the food and personal care industries.

Kindly Reminder:

Please tell us the following information when you send us an inquiry. Based on your message, we will suggest the optimum solution to you for reference. Thank you.

1. Your product

2. Filling Range

3. Bottle/Jar material

4. Bottle/Jar dimension

Packaging Exambers:

| Automatic 6 Heads Liquid Filling Machine | |||

| Model | LFZ-02 | LFZ-04 | LFZ-06 |

| Number of filling nozzles | 2 Nozzle | 4 Nozzle | 6 Nozzle |

| Filling range | 1000-5000ml | ||

| Filling speed | ≤15-50 bottles/min | ≤20-35 bottles/min | ≤40-50 bottles/min |

| Measurement accuracy | ≤±1% | ||

| Power | 3.2KW | 2.5KW | 5KW |

| Voltage | AC380V 50-60HZ | ||

| Air pressure | 0.5-0.7 Mpa | ||

| Dimension | 1800*1500*2200mm | 2200*1600*2200mm | 4600*1800*2200mm |

| Weight | About 600kg | About 1000kg | About 2000kg |

| Autoamtic Capping Machine | |||

| Model | LFX-JX-01(Four wheel capping) | LFX-GS-150(Eight wheel capping) | LFX-GS-250(Six wheel capping) |

| Capacity | 20-50Bottles/min | 40-100Bottles/min | 30-80Bottles/min |

| Bottle cap diameter | Φ22mm-Φ80mm | Φ18mm-Φ80mm | Φ18mm-Φ80mm |

| Bottle diameter | Φ35mm-Φ140mm (Could be customized) | ||

| Bottle sealing height | 38mm-300mm | ||

| Power | 1.5KW | 2KW | 1.5KW |

| Voltage | 220V, 50HZ | ||

| Air pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.5-0.7Mpa |

| Weight | 250kg | 350kg | 300kg |

| Dimensions | H3000*W800*L1600mm | H3120*W1544*L2122 | H3100*W1244*L2122 |

| UV Laser Coder Coding Machine | |||

| Model | ZS-UVC1 | ||

| Output power | 3W/5W/10W | ||

| Machine power | 800W | ||

| Laser wavelength | 355nm | ||

| Control system | 10.2-inch touch screen(Linux system) | ||

| Production speed | 0-130m/min(depending on the material) | ||

| Minimum line width | 0.0012mm | ||

| Marking range | 110x110mm(optional) | ||

| Marking speed | >1200mm/s PVC tubes:40 m/minPET bottles:20000 bottles/hCoated cartons:35 m/min | ||

| Cooling method | Water cooling | ||

| Multi-language | Chinese, English, French, Spanish, German, Russian, Korean, Arabic, etc (can be added) | ||

| Suitable material | Glass, metal, plastic, wood, leather, acrylic nano, cloth, ceramic, purple sand, and coated film (Actual testing is required) | ||

| Package size | About 630x430x210mm(Lens), About 680x410x560mm(industrial Chiller), About 670x410x560mm(Power Supply Host) | ||

| Package weight | About 13kg(Lens), About 24kg(industrial Chiller), About 13kg(Power Supply Host) | ||

1. Servo-driven filling nozzle reduces air bubbles for precise, consistent liquid filling.

2. Built-in laser coder prints sharp, permanent batch codes and expiration dates.

3. Handles thick or foamy liquids like juices, oils, and cleaning products with ease.

4. High-accuracy filling minimizes waste while meeting strict quality requirements.

5. Easily connects to capping and labeling machines for complete automation.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail