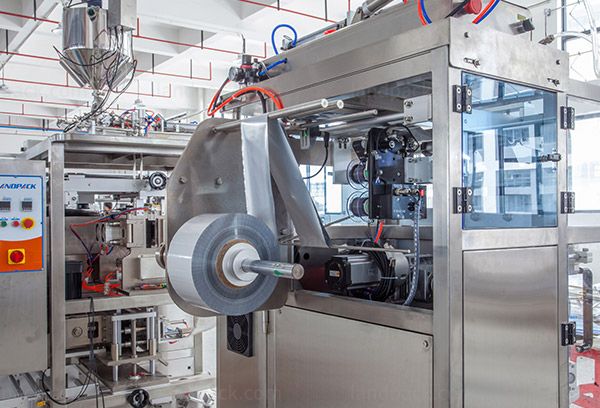

Single Lane Juice Special Shaped Stick Bag Packing Machine

Model : LDBK-140L

Advantages :

It features a fully automatic process—heating, mixing, piston pump filling, bag forming, coding, sealing, and custom die-cutting—making it perfect for industries like food, cosmetics, and household products. The machine supports both thick and thin liquids, producing 20–30 pouches per minute with attractive, custom-shaped designs.

Application :

The Packaging Machine is ideal for packaging a variety of liquids, including juice, sports gel, coffee creamers, sauces, honey, and detergents.

Kindly Reminder :

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample :

Name | Landpack Single Lane Stick Pack Machine | |

Model | LDBK-140L | |

| Dosing Method | A: Piston pump 1-30ml; B: Piston pump 2-42ml; C: Magnetic pump 3Liter/min (for pure liquid or oil product) | |

| Hopper type | A: Single layer SS304 hopper; B: Double jacket SS304 hopper; C: Magnetic pump hose connection to raw liquid tank | |

Packing speed | 20-45 bag/min (1200-2700bag/min) | |

Bag size range | L 40-150mm ; W 15-100mm | |

Bag Seal type | Stick /pillow | |

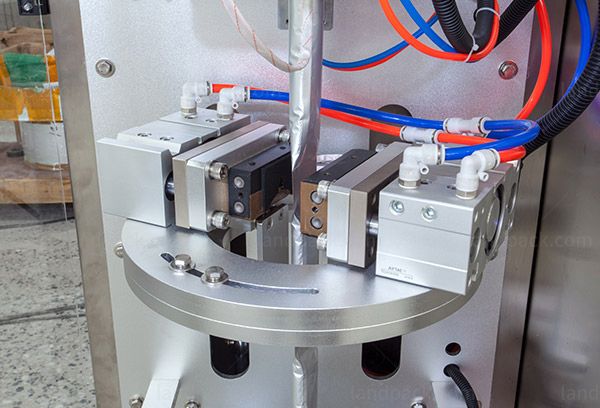

| Cut type | A: Teeth cut; B: Straight cut C: Round cut D: Irregular cut (Stick Width within 40mm) | |

Film thickness | 0.05-0.1mm | |

Film material | Laminated film such as paper/PE, aluminum/PE, PA/PE, PET/PE, filter paper | |

Drive method | Electricity + Pneumatic | |

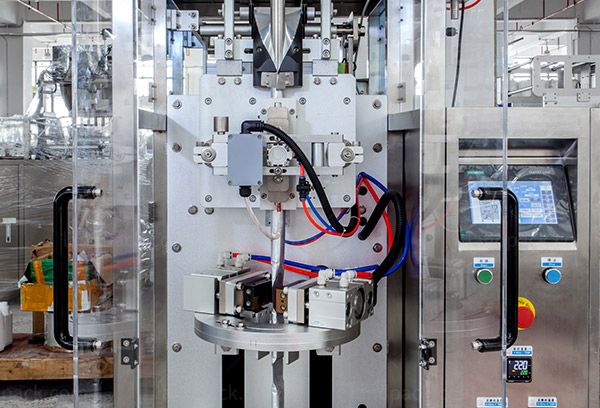

Control style | PLC control system+English/Chinese screen (Or customized panel) | |

Power | 1.8KW | |

Power supply | AC220V 1phase 50Hz/ AC380V 3phases 50Hz | |

| Air consumption | 0.4cbm/min 0.8Mpa | |

Dimension | 750x710x1780 mm | |

HS CODE for export | 84223030 | |

1. The fully automated process integrates heating, mixing, piston pump filling, bag forming, coding, sealing, and custom die-cutting for smooth operation.

2. It features irregular mold cutting to produce aesthetically pleasing pouches in unique, customizable shapes.

3. Using a piston pump system, it handles both viscous and non-viscous liquids for versatile filling and accurate dosing.

4. Operation is user-friendly via a Siemens touchscreen with PLC control, ensuring stable, intelligent, and simple use.

5. High packing efficiency is achieved with speeds of 20–30 bags per minute to boost productivity.

6. Built from stainless steel materials, the machine ensures long-lasting durability and meets hygiene standards.

7. Precise sealing temperature control is maintained within ±1°C using an intelligent PID temperature controller for consistent quality.

8. It works flexibly with various PE composite films, including pure aluminum, aluminum-plated, nylon, and similar structures.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail