Automatic Juice Shaped Pouch Packing Machine | Multi Track Packaging Machine

Model: LDFS-620L

The LDFS-620L special-shaped bag packaging machine consists of a main unit, hopper, SUS304 volumetric pump, film feeder, laser coder, water cooling system, touch screen, and sealing and cutting system. It is controlled by a PLC system.

Application:

It is suitable for packaging liquids such as juice, cosmetics, shampoo, conditioner, creams, oils, sauces, feed oil, liquids, perfumes, pesticides, emulsifiable concentrates, traditional Chinese medicine, and cough syrups.

What is a special-shaped bag packaging machine?

The custom-shaped bag packaging machine breaks away from the traditional three- or four-side sealed bag format and can produce flexible bags with highly customized contours, such as rounded corners, self-supporting spouts, or bottle or heart shapes.

Application:

It is suitable for packaging liquids such as juice, cosmetics, shampoo, conditioner, creams, oils, sauces, feed oil, liquids, perfumes, pesticides, emulsifiable concentrates, traditional Chinese medicine, and cough syrups.

Package Type:

We offer tailored packaging solutions with diverse bag shapes, such as custom-designed and multi-layered composite bags, based on client requirements.

Customized packaging design can enhance product value and brand recognition. Furthermore, uniquely shaped bags are easy to carry and share, and have significant market potential, especially for e-commerce, small-scale promotions, and sample packaging.

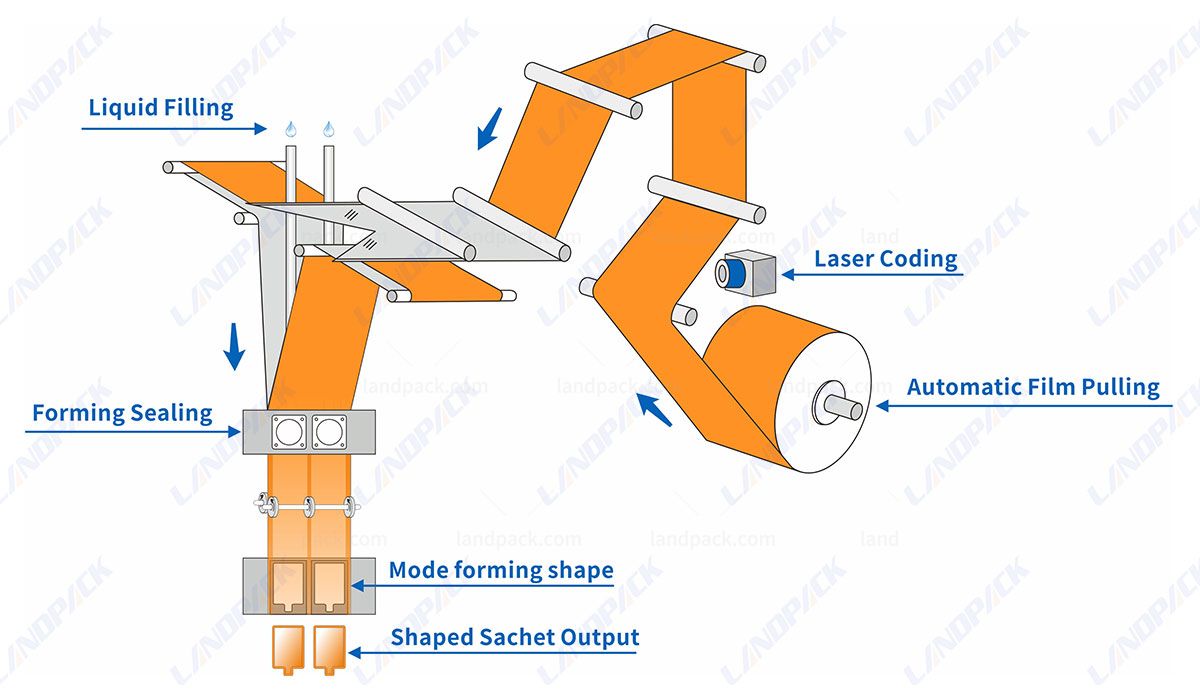

Workflow:

Hopper - Automatically feeds liquid into the machine.

Coder - Date laser printer.

Film Feed - Automatic bag formation via packaging rollers.

Fill and Seal - Automatically fills liquid via a metering pump system.

Shape Cutting - Die-cutter heat seals and cuts for final output.

Model | LDYX-480L | LDYX-620L |

| Track number | 2-4 Tracks | 2-4 Tracks |

| Filling Method | 1. Piston pump, 2. Peristaltic pump | |

| Production capacity | 20-30 cycle/min | |

| Bag Size | L: 50-170mm; W: 70-230mm | L: 50-170mm; W: 100-300mm |

| Film W&D | Max. 500mm; 0.07-0. 10mm | Max. 620 mm; 0.07–0.10 mm |

| Sealing Type | Irregularly shaped bag | |

| Air & Power | 220V/380V 50HZ, 5.0kw | 220V/380V 50HZ, 5.5kw |

| Air Consumption | 0.8mpa; 0.8m³/min | 0.8mpa; 0.8m³/min |

| Weight | 800 KG | 900 KG |

Machine size | 2600*1350*2350 mm | 2600*1450*2350 mm |

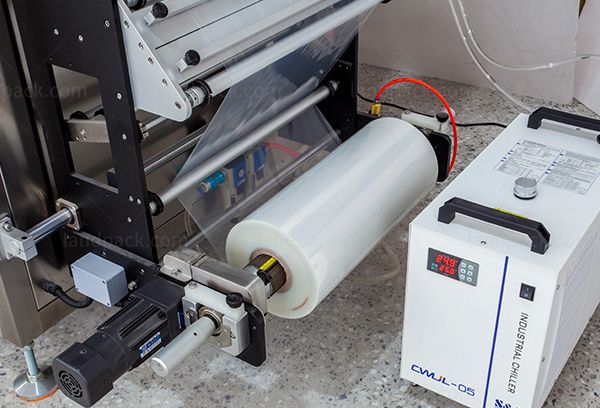

Laser marking machine A laser marking machine uses a high-energy laser beam to create permanent marks (text, patterns, barcodes) on material surfaces through |  |

| Water cooling system for the laser printer The laser printer generates significant heat during operation. A water cooling system circulates cooling water to stabilize the laser temperature within a range of ±0.1°C to ±1°C, preventing wavelength shift or power fluctuations due to overheating. |

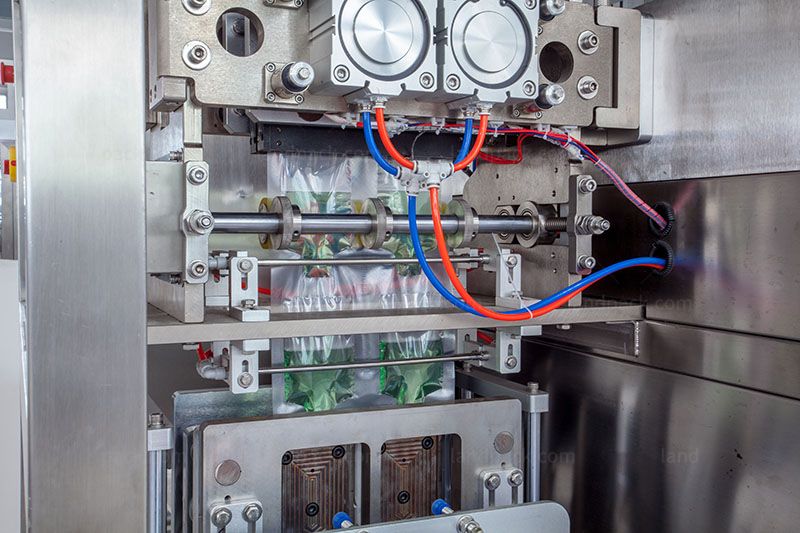

Film forming structure and heat sealing system This machine is primarily designed for packaging uniquely shaped bags. It features a pneumatic sealing system and a separate punching unit. The edges of the finished bags, crafted with premium imported materials, are smooth, burr-free, and fully leak-proof. |  |

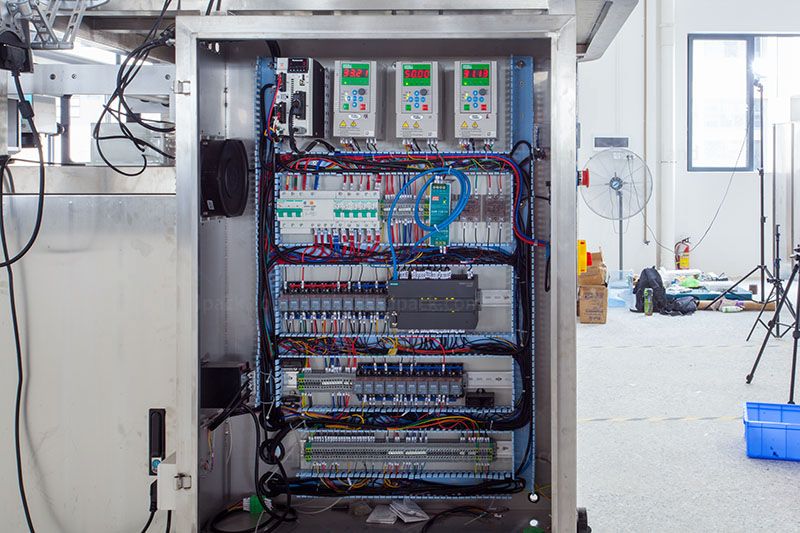

| Advanced electric box design * The cabinet integrates a variety of electrical modules with different functions. * A PLC control system and servo bag-pulling system ensure precise positioning with minimal deviation and high equipment stability. * A circuit breaker (for power on/off and overload/short-circuit protection) is also included. |

Automatic waste collection system Throughout the packaging process, creating special-shaped bags generates waste, which is managed by an integrated automatic waste collection system designed to efficiently gather debris. |  |

Machine Key Components:

* Laser Coding: Print the date onto the film using a laser marking machine.

* Hopper: Liquid storage

* SUS304 Volumetric Pump: Volumetric liquid delivery to the machine

* Filling Nozzle: Precisely dispenses liquid/paste into pouches.

* Control Panel: Touchscreen interface for setup, adjustment, and monitoring.

* Form Structure: making the sachets by the packaging roll

* Mode Forming Shape: Die-cutter heat seals and cuts

Get Price & More Detail