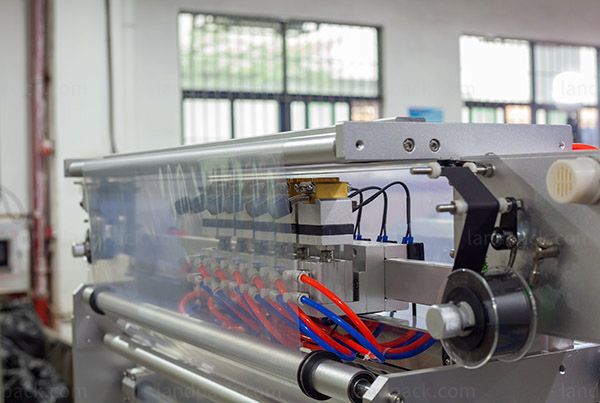

Automatic 4 Multi Lane Sachet Packing Machine For Ketchup

Model: LDFS720L

Application:

Automatic 4 multi lane sachet packing machine for ketchup, it suitable for viscous sauce packaging, such as ketchup, chili sauce, honey, pizza sauce, peanut butter, chocolate sauce, cream, shampoo, hand sanitizeretc, etc.

Advantages:

Sachet forming, product dosing, filling and sachet sealing processes, with single cutting or string sachet cutting.

Application:

Automatic 4 multi lane sachet packing machine for ketchup, it is suitable for filling liquids and sauce of any fluidity in various industries.

Examples:

Ketchup, syrup, peanut butter, chocolate sauce, juice, shampoo, pizza sauce honey, jam, paste, oil, etc.

Kindly Reminder:

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample:

Model | LDFS-480L | LDFS-720L | LDFS-960L |

| Track Number | 4~6 Track | 4~10 Track | 4~12 Track |

| Filling Method | 1.Piston pump; 2.Peristaltic Pump | ||

| Capacity | Max.40 cycle/min | ||

| Sachet Size | L:45--120mm; W:35-60mm | L:45--120mm; W:35-90mm | L:45--120mm; W:35-120mm |

| Film Width & Thickness | Max.480mm;0.07-0.1mm | Max.720mm;0.07-0.1mm | Max.960mm;0.07-0.1mm |

| Sealing Type | 3/4 sides sealing | 3/4 sides sealing | 3/4 sides sealing |

| Cutting Type | 1. Straight Cutting; 2. Zig Zag Cutting; 3. Continuous Cutting | ||

| Air & Power | 0.8 mpa 0.8m³/min; 2.8kw | 0.8 mpa 0.8m³/min; 4.1kw | 0.8 mpa 0.8m³/min; 5.5kw |

| DIM & WT | 950*1470*1750mm; 300kg | 1153*1654*1750mm; 400kg | 1415*1686*2130mm; 500kg |

1. Multi lanes machine can produce multi lanes bags at same time.

2. Machine main function: automatic split film at right position, liquid measuring and filling, multi lanes bag form fill seal, cutting, sensor tracking, counting capacity.

3. Other function: Emergency stop, set capacity to auto stop machine, count capacity and Zero the count, ready bag output, manual test machine each step etc.

4. Stainless steel contact part and the machine outer shell, high feature for liquid running environment.

5. High precision photocell sensor for auto tracking the eye mark printing on the film roll, so cut each bag at precisely position.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail