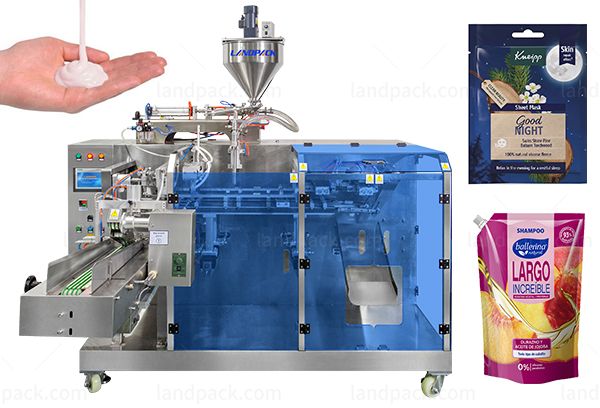

Automatic Shampoo Bottle Filling Machine For 100ml 200ml 300ml 400ml 500ml 750ml 1L Etc

Model : LD-ALF01

Application :

Ideal for filling and capping small- to medium-size bottles (100 ml–1 L) across multiple industries: cosmetics & personal care: shampoo, conditioner, body wash; daily chemicals: liquid soap, dishwashing, laundry detergent; food & beverages: sauces, oils, syrups, honey, essential oils ; pharmaceuticals & healthcare: oral liquids, sanitizers.

Application :

Ideal for filling and capping small- to medium-size bottles (100 ml–1 L) across multiple industries: cosmetics & personal care: shampoo, conditioner, body wash; daily chemicals: liquid soap, dishwashing, laundry detergent; food & beverages: sauces, oils, syrups, honey, essential oils ; pharmaceuticals & healthcare: oral liquids, sanitizers.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packaging Sample :

| Model | LD-ALF01 |

| Filling Range | 50-1000ml(Customizable) |

| Filling Speed | 15-50 bottles/min |

| Measurement accuracy | ±1% |

| Power | 2 KW |

| Working power supply | 220V, 50Hz |

| Working pressure | 0.6-0.8MPa |

| Weight | 500kg |

| Size | L4000*W1320*H2090(mm) |

1. Features a 10-head gear pump filling system with two independent groups (5 heads each) for simultaneous filling of different products.

2. Uses bottom-up (dipping) nozzles to minimize bubbles and foam during filling.

3. Automates cap feeding and capping with a vibratory feeder and four-wheel capping station, reducing manual work.

4. Includes ink-jet coding on bottle bottoms for traceability and compliance.

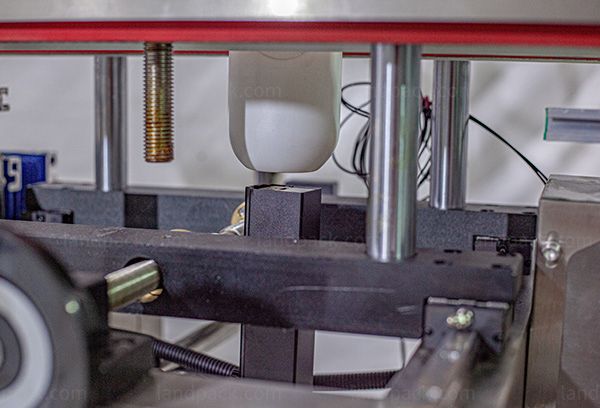

5. Equipped with sensors to prevent filling if no bottle is detected.

6. Ensures high accuracy (±1%) with adjustable fill volumes and recipe storage.

7. Made with food/pharma-grade 304/316L stainless steel for easy cleaning and GMP compliance.

8. Operates via PLC touchscreen for centralized control, real-time monitoring, and fault alerts.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail