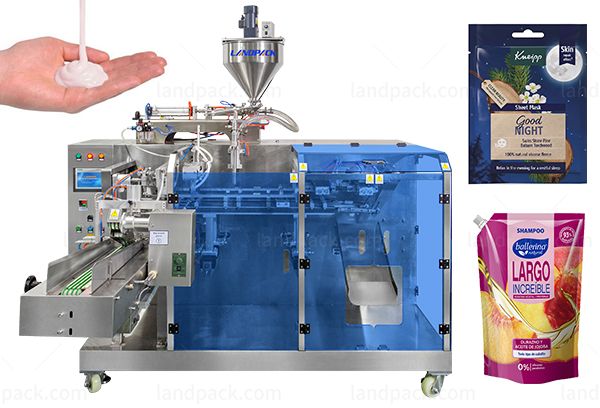

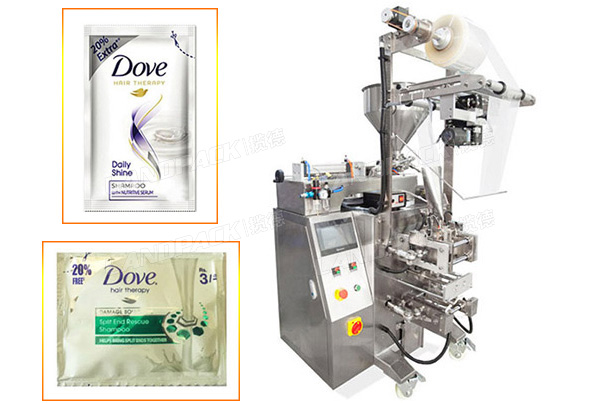

Automatic Shampoo Tube Filling And Sealing Machine

Model: LFF-FW-00

Application:

Suitable To Pack Liquid Product Or Paste Materials, Such As Shampoo, Ketchup, Jelly, Sauce, Etc.

Description of the main packaging process:

automatic tube feeding → color code alignment → blanking → internal heating → external heating → embossing (can be coded) → tail trimming → finished product export

Application:

Scope of application: used in packaging in medicine, daily chemical, food, chemical, and other industries, such as shampoo, ointment, adhesive, AB glue, epoxy glue, skin cream, hair dye, shoe polish, toothpaste, and other liquid or paste-like materials Loading and sealing.

Filling container: plastic tube; composite tube.

Optional supporting devices: three-dimensional packaging machine, cartooning machine, sealing and cutting machine, heat shrinking machine, etc.

Kindly Reminder:

We have an experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers:

| Model | LFF-FW-00 |

| Yield | 20-35 pcs/min |

| Pipe diameter | Φ10mm-Φ50mm(customizable) |

| Tube height | 20mm-250mm(customizable) |

| Control system | PLC |

| Power supply | 220V、50Hz |

| Air consumption | 0.3m³/min |

| Dimension | 1280mm*10100mm*1700mm(L*W*H) |

| Equipment Material | 304 |

| Weight | 600KG |

1. The filling speed and measurement accuracy are convenient and adjustable, with high adjustment accuracy and good stability;

2. The replacement of the base is suitable for filling and sealing various specifications of pipes, the sealing appearance is neat and tidy, and the sealing is firm;

3. All parts of the machine that contact materials are made of stainless steel SUS304;

4. The machine can be equipped with various filling methods of different specifications to meet the filling requirements of different viscosity;

5. The typing station automatically prints the word code on the position required by the craft;

6. Photoelectric benchmarking workstation, with high-precision probes, stepping motors, and other control patterns in the correct position;

7. It adopts a PLC console, which is portable and convenient for a brief introduction.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail