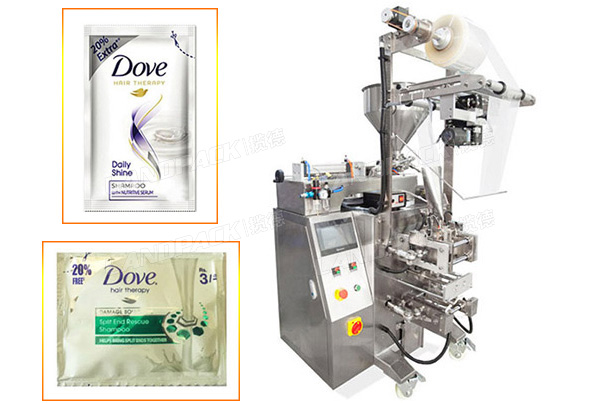

Shampoo Sachet Packing Machine Automatic Liquid Vertical Packing Machine

Model: LD-320L

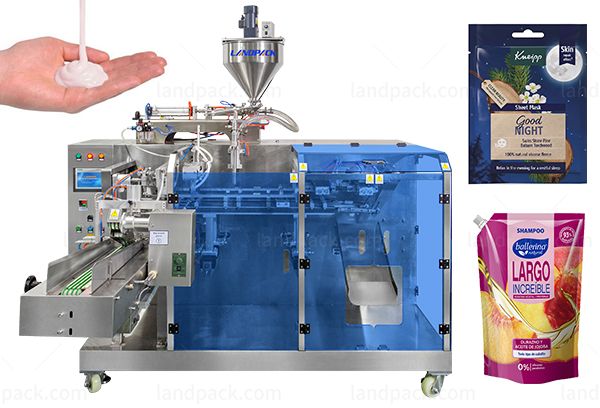

The vertical pouch machine comes with dual piston pumps for exact, safe dosing of pastes, liquids, and viscous substances.

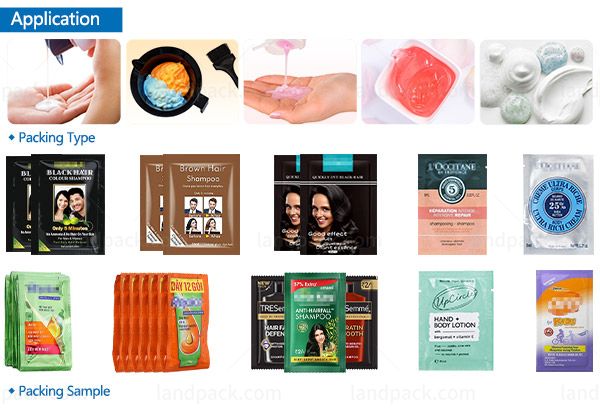

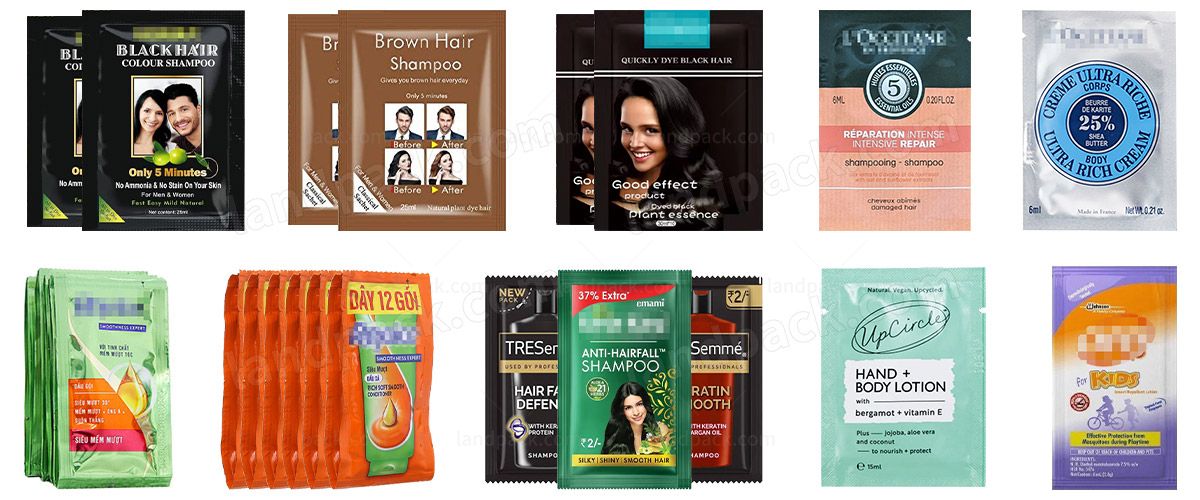

Application:

It is ideal for packaging shampoo and ketchup, mayonnaise, juices, salad dressings, liquid soap, body wash, cooking oil, and liquid detergents etc.

Application:

It is ideal for packaging shampoo and ketchup, mayonnaise, jam, condensed milk, juices, salad dressings, liquid soap, body wash, cooking oil, and liquid detergents, etc.

Package Type:

This equipment accommodates single-use sachet formats, making it ideal for packaging condiments, beauty samples, personal hygiene fluids, and common household liquids.

Suitable Products:

Equipped with dual piston pumps, this machine is built for consistent dosing of liquids and viscous products used across food, cosmetic, and household industries.

Sauces & Condiments: Chili sauce, ketchup, soy sauce, salad dressings, flavored oils, liquid seasonings, and cooking pastes.

Personal Care & Cosmetic Liquids: Shampoo, conditioner, shower gel, lotions, essence liquids, beauty serums, and sample-size skincare products.

Household & Daily-Use Liquids: Detergents, cleaners, disinfectant liquids, fabric softeners, lubricants, and other fluid household products.

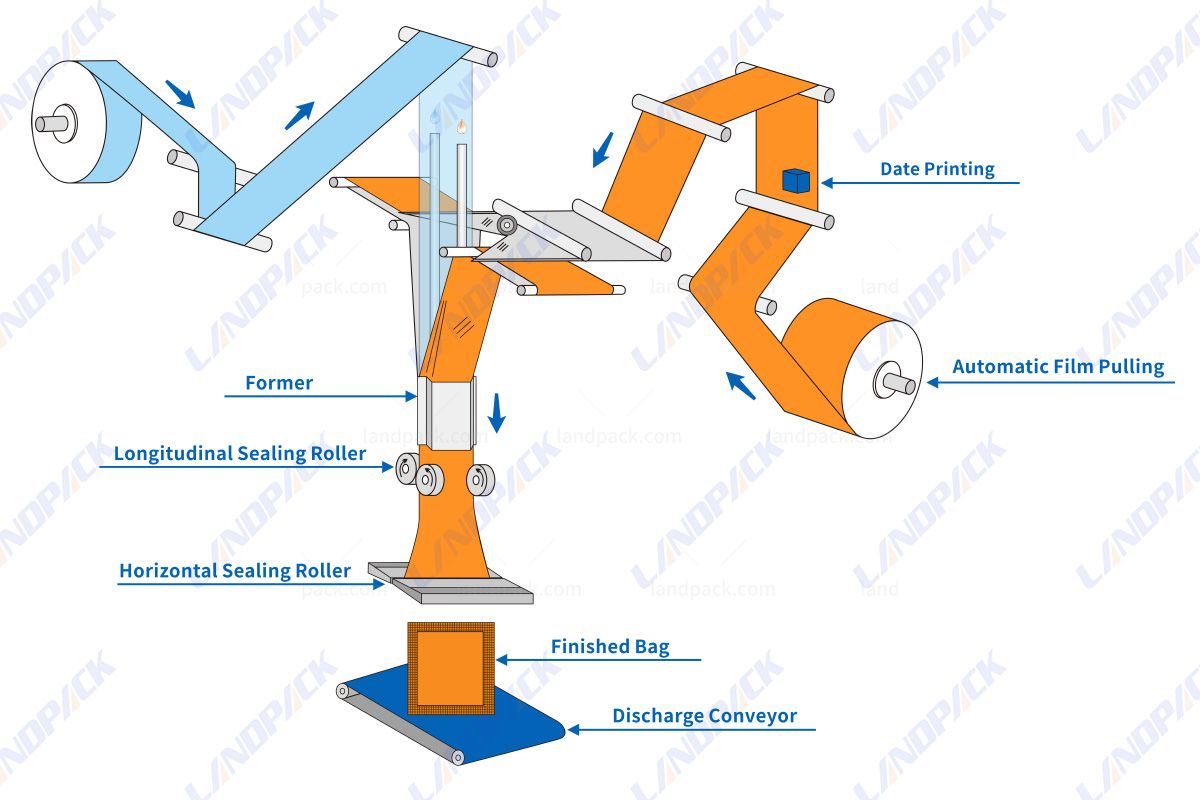

Process Workflow:

Automatic Film Unwinding – The film is fed into the machine with precise tension regulation, ensuring stable handling for the smooth creation of 4-side seal sachets.

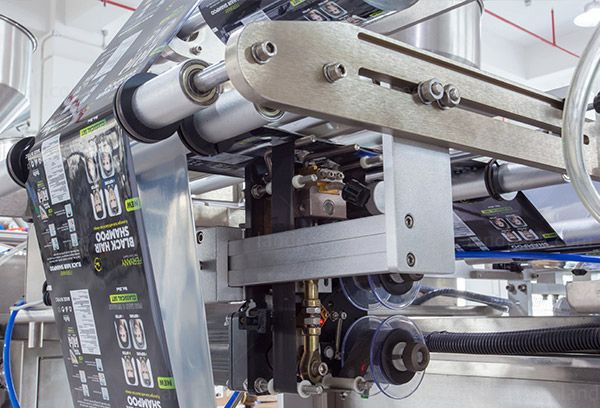

Ribbon Coding System – Before the pouch is formed, a thermal ribbon printer applies batch numbers or expiration dates directly onto the film surface.

Dual-Piston Filling Mechanism – Equipped with dual piston pumps, the system accurately doses liquids and viscous materials (like sauces or gels) with consistent repeatability.

Full Perimeter Vertical Sealing – Vertical bars seal all four edges of the film to produce flat, secure sachets with strong seams that guarantee leak-proof integrity.

Simultaneous Sealing & Cutting – Horizontal jaws perform the top seal and cut the sachets in a single motion, maintaining uniform pouch size even at high production speeds.

Anti-Drip Tray (Optional) – To maintain a clean machine environment and spotless packaging, this optional tray catches any liquid drips between filling cycles.

Product Ejection – The fully formed 4-side seal sachets are discharged via conveyor, ready for quality inspection, boxing, or downstream packaging.

| Model | LD-320L | LD-380L |

| Film width | 120-320mm | 180-380mm |

| Bag length | 50-200mm | 60-280mm |

| Bag width | 50-150mm | 60-180mm |

| Diameter of film roll | Max.300mm | Max.320mm |

| Packing speed | 35-70bag/min | |

| Measuring range | 50-500ml | 50-750ml |

| Film thickness | 0.04-0.07mm | |

| Power | 220V 50/60Hz 2.2KW | 220V 50/60Hz 2.5KW |

| Machine size(L*W*H) | 970*680*1950mm | 1100*800*2150mm |

| Machine weight | About 300kg | About 450kg |

Machine Key Components:

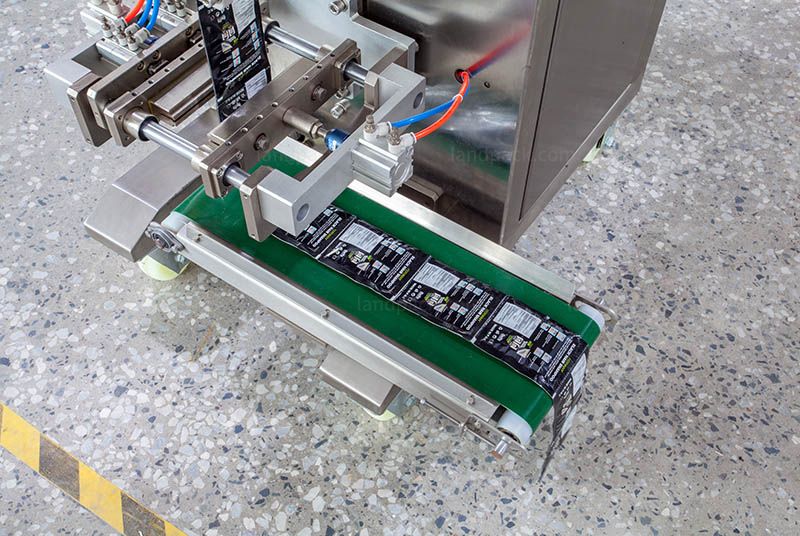

1. Horizontal Sealing and Cutting

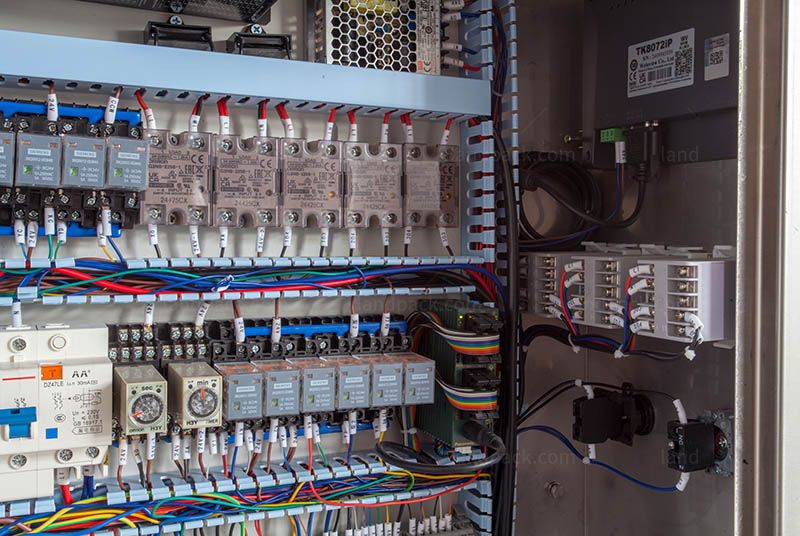

2. Control Panel

3. Piston Liquid Pump

4. Roll Film Feeding

5. 4 Side Vertical Sealing Bar

6. Finished Product Conveyor

Feature:

Control Panel A user-friendly touch screen centralizes all parameters, allowing quick setup of filling volume, sealing temperature, and cycle speed. |  |

| Coding Machine Integrated coding prints production dates, batch numbers, or traceability data directly onto each pouch. |

Sealing System The horizontal sealing station applies precise heat and pressure to close the pouch after filling. |  |

| 4-Side Vertical Sealing Bar The vertical sealing bar applies uniform heat and pressure to create clean, strong four-side seams. |

Finished Product Conveyor The discharge conveyor smoothly transfers sealed pouches out of the machine, preventing wrinkles or damage. |  |

| Electrical Box All electrical components are securely housed in an organized, dust-protected enclosure. |

Get Price & More Detail