Spout Pouch Filling Machine | High Speed Liquid Soap Filling and Capping Machine

Model: LD-SVFC1

Introduction:

Landpack's spout pouch filling system provides a complete solution for filling and capping spout pouches. The rotary 10-head filler can meet your needs for high productivity and large-capacity pouch filling.

Application:

It is widely used for products like laundry detergent, drinks, soy milk, butter, puree, fruit juice, sauce, jelly, daily chemicals, ketchup, etc.

The machine can easily switch between top-spout and side-spout pouches, with a speed of 80–100 pouches per minute, depending on the packaging, product, and capacity

Application:

Laundry detergent, drinks, soy milk, puree, fruit juice, sauce, jelly, daily chemicals, dairy, ketchup and other products

Custom filling options for special products are available:

1. Mixing and blending multiple liquids

2. Hot-filling or retorting products

3. Liquids containing particles or viscous liquids

Customized packaging solutions:

With advanced manufacturing facilities and a skilled engineering team, we can design, build, and fine-tune machines for different products, packaging types, and production scales. From concept to final assembly, every step is handled in-house to ensure precision. We have six production workshops to meet your diverse packaging needs.

Workflow:

| Model | LF-XZD1T | LF-XZD2T | LF-XZD4T | LF-XZD6T | LF-XZD10T |

| Filling Head | 1 | 2 | 4 | 6 | 10 |

| Voltage | 220V/110V, 50-60Hz | ||||

| Power | 1KW | 3KW | 3KW | 3KW | 3KW |

| Filling Speed | 1200 bph | 1500-2100 bph | 3300-3900 bph | 4500-6000 bph | 4800-6000 bph |

| Filling Range | 10-300ml | 30-2000ml | 100-500ml | 10-350 ml | 50-2000ml |

| Filling Accuracy | ±1% | ||||

| Air Pressure | 0.4-0.7MPa | 0.4-0.7MPa | 0.8Mpa | 0.8Mpa | 0.5-0.8Mpa |

| Machine Weight | 300kg | 260KG | 2600kg | 2500kg | 700KG |

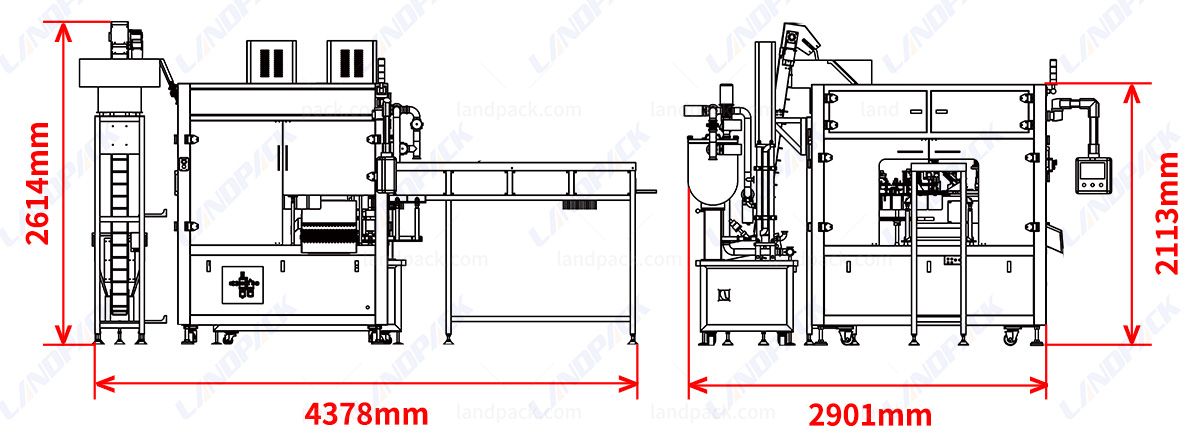

| Machine Size | 1500*1200*1200mm | 2500*2200*1900mm | 1400*1230*1900mm | 2450*1900*2200mm | 2450*1900*2200mm |

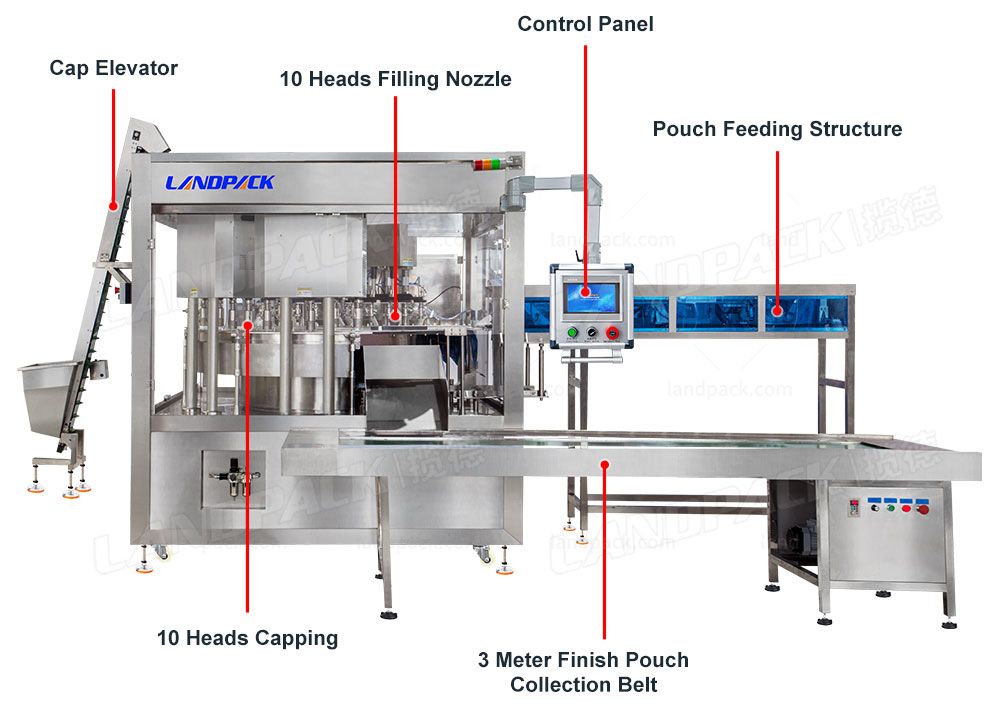

Compact 10-Head Spout Pouch Filling & Capping Machine Integrates filling and capping in a single unit, saving valuable floor space. |  |

| Servo-Controlled Gear Pump Filling Each nozzle is individually driven by a servo motor with gear pump technology, ensuring high precision and consistent filling volumes. |

High-Speed Performance Achieves an overall output of 80–100 bags per minute with all 10 heads in operation. |  |

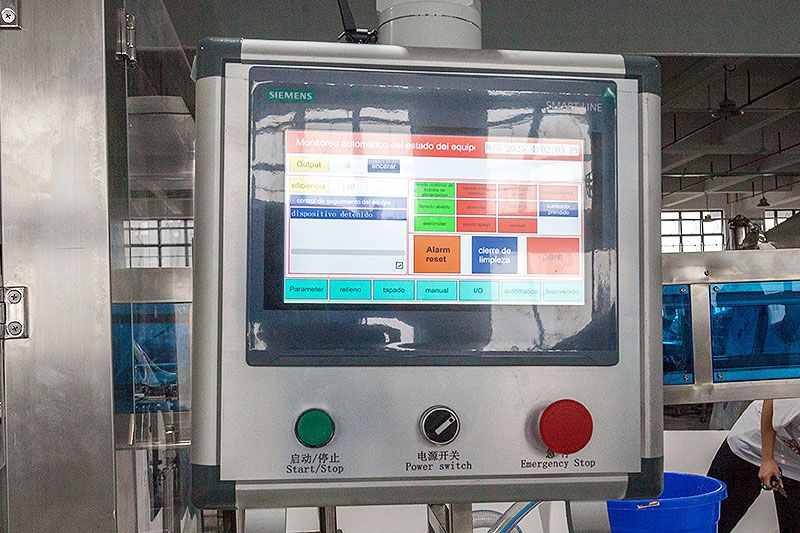

| User-friendly Control Simple setup process, interactive on-screen instructions, and a vivid full-color touchscreen with clear icons make operation straightforward. The integrated industrial PC enables quick parameter adjustments, personalized presets, and convenient local language settings for smooth, efficient use. |

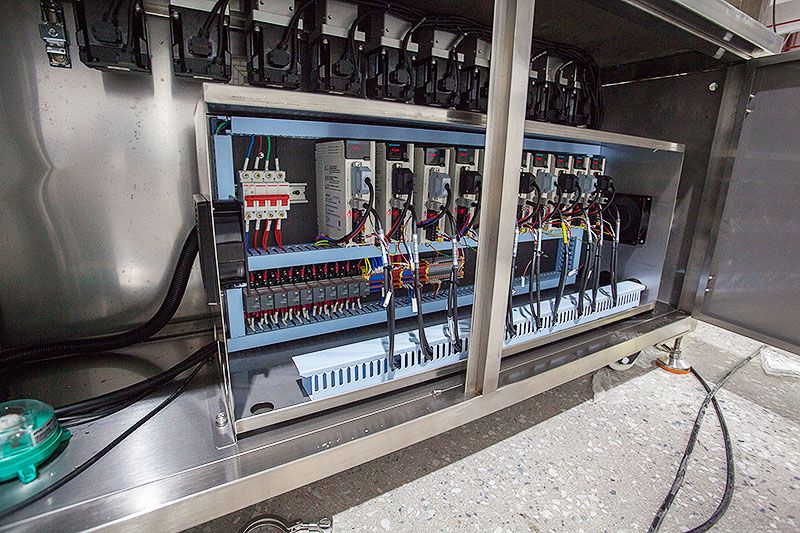

Maintenance Made Simple * Manules / Videos of machine installation, adjusting, setting, maintenance are available for you. * Service interval tracking tailored to machine usage * Comprehensive self-diagnostics and fault monitoring * Customizable access rights for individual controls * Easily replaceable sensors with plug-and-play connectors |  |

Machine Key Components:

* Cap Elevator – Lifts caps from hopper to capping.

* Dust Cover: Protects internals and product from contamination.

* Filling Nozzle: Precisely dispenses liquid/paste into pouches.

* Control Panel: Touchscreen interface for setup, adjustment, and monitoring.

* Pouch Feeding Structure: Guides empty pouches into position for filling.

* Finished Product Conveyor: Transfers filled & capped pouches to next stage.

Get Price & More Detail