Juice Premede Pouch Packing Machine | Automatic Shape Pouch Doypack Packing Machine

Model: LDSP-140SL

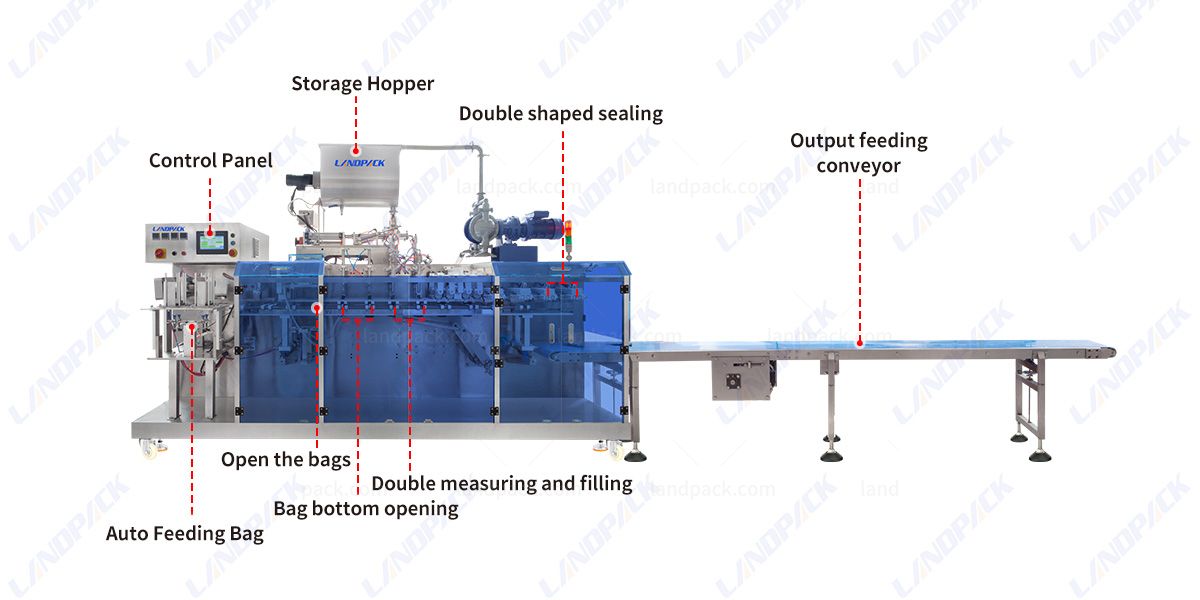

The horizontal premade twin-pouch packaging machine is designed for various liquid packaging. Its twin-pouch structure allows simultaneous filling of two compartments, improving productivity while delivering clean, attractive, and reliable liquid packaging.

Application:

This machine is ideal for packaging a wide range of liquid products such as juices, nutritional liquids, energy supplements, flavored drinks, sauces, and medical or healthcare liquids.

Application:

This machine is ideal for packaging a wide range of liquid products such as juices, nutritional liquids, energy supplements, flavored drinks, sauces, and medical or healthcare liquids.

Package Type:

Designed to accommodate multiple premade pouch formats with smooth, reliable performance and excellent sealing results. Compatible pouch types include stand-up pouches, flat or three-side seal pouches, shaped or contour pouches, spout pouches, zipper bags, and quad-seal or side-gusset pouches.

Suitable Products:

This machine is highly versatile and supports a broad range of liquid and semi-liquid products across multiple industries.

Food & Beverage Products: Juices, smoothies, dairy drinks, liquid seasonings, syrups, and drink concentrates.

Health & Nutritional Products: Herbal extracts, tonics, liquid supplements, nutraceutical formulas, and electrolyte liquids.

Cosmetic & Household Liquids: Shampoo, conditioners, serums, hand wash, detergents.

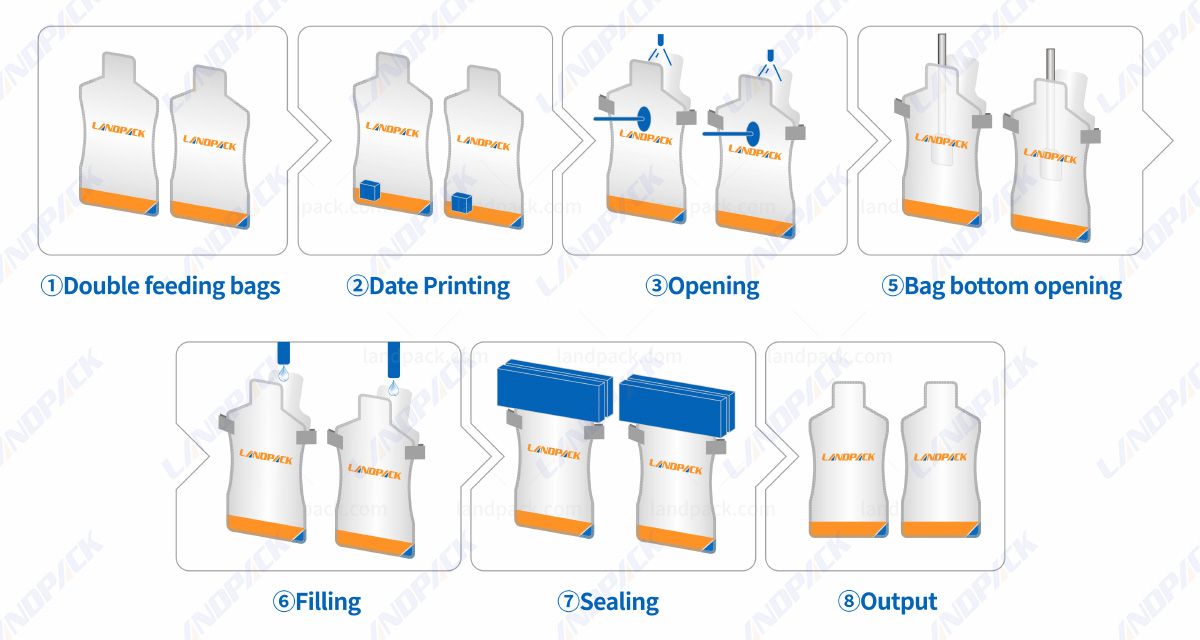

Workflow:

1. Double Bag Feeding – Two premade pouches are automatically picked and fed simultaneously for high-speed production.

2. Date Printing – Expiry date, batch code, or production info is printed accurately on each pouch.

3. Bag Opening – Suction pads open the top of the pouch smoothly and reliably.

4. Bottom Opening – Ensures the pouch is fully expanded for clean and accurate filling.

5. Filling- Products that are liquid or semi-liquid are precisely dispensed into each pouch.

6. Sealing- Heat sealing creates a leak-proof, strong closure.

7. Output- The finished pouches are discharged onto the conveyor neatly for collection or downstream packaging.

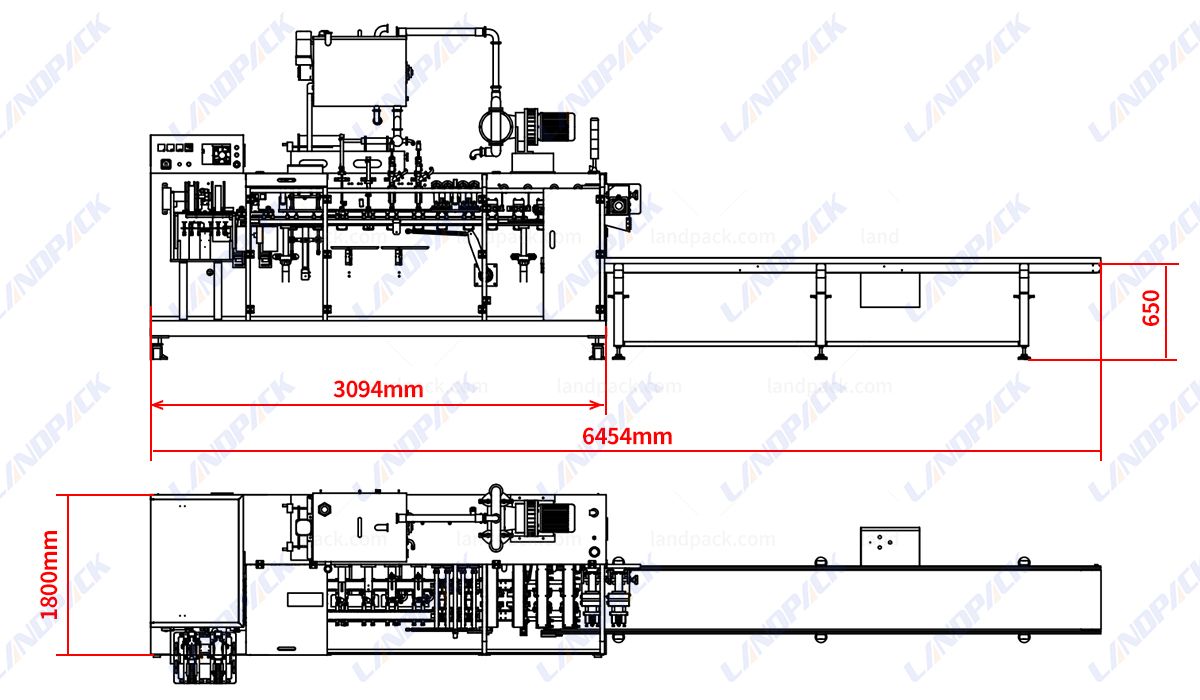

| Type | LDSP-140S | LDSP-85F |

| Bag Type | 3-side, 4-side sealing bags, stand-up bags, handbags, spout bags, zipper bags, compound bags, etc. | |

| Bag Size | 90-140mm/100-250mm/(W*L) | 60-90mm/100-300mm/(W*L) |

| Filling Range | 10-500ml | 5-300ml |

| Packing Speed | 10-45 bags/min | 100-160 bags/min |

| Machine Weight | 900KG | 1500KG |

| Total Power | 6KW | 7.5KW |

| Dimensions(L*W*H) | 3093*1366*1360mm | 3600*1366*1360mm |

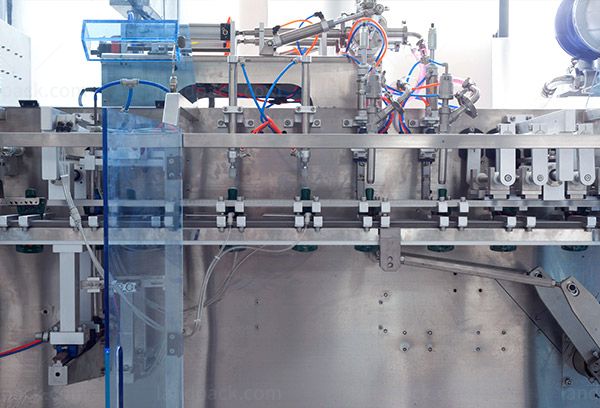

Machine Key Components:

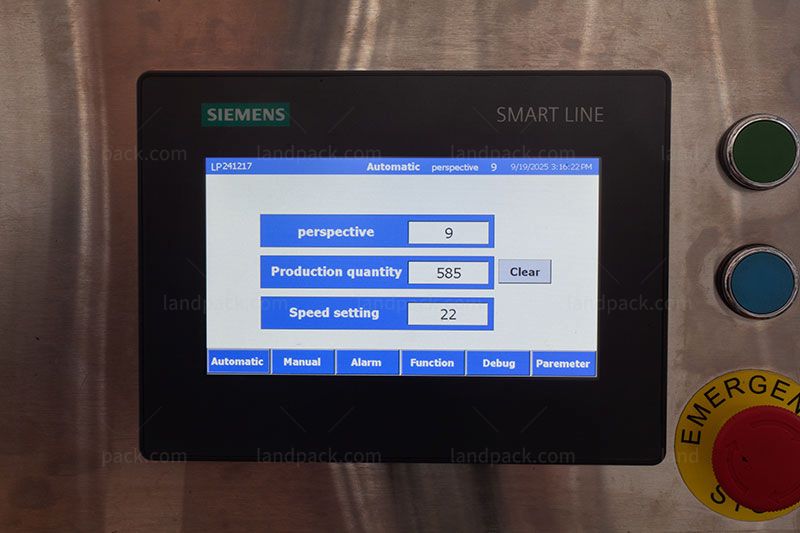

1. Control Panel

2. Storage Hopper

3. Auto Feeding Bag

4. Open the Bags

5. Bag Bottom Opening

6. Double Shaped Sealing

7. Output Feeding Conveyor

Feature:

Control Panel Intuitive touch-screen control system enables effortless parameter adjustment, live status display, and rapid fault diagnosis for smoother operation. |  |

| Automatic Pouch Feeding Dual-lane pouch feeding mechanism reliably selects and positions premade bags, maintaining consistent high-speed performance. |

Product Hopper The high-capacity hopper ensures a steady product supply, supporting long, uninterrupted production runs. |  |

| Pouch Opening Unit Dual vacuum arms precisely open each pouch, ensuring proper alignment before entering the filling section. |

Bottom Spreader System Mechanical expansion of the pouch bottom enhances filling stability, minimizes overflow, and improves dosing accuracy. |  |

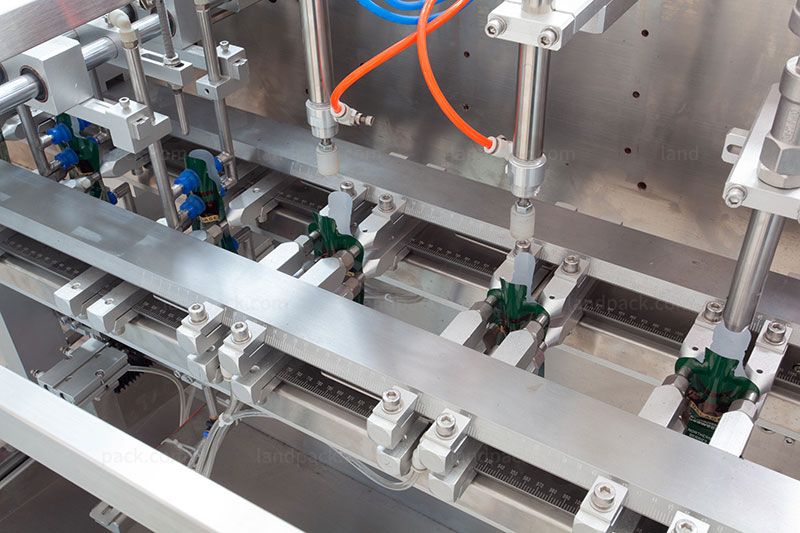

| Dual Filling System Twin synchronized dosing units provide accurate and efficient filling of liquids and semi-liquids, maximizing productivity. |

Dual Shaped-Sealing Station Reinforced sealing heads produce clean, durable shaped seals that enhance pouch appearance and prevent leakage. |  |

| Discharge Conveyor Completed pouches are smoothly transferred onto the conveyor, ready for inspection, packing, or downstream processing. |

Get Price & More Detail