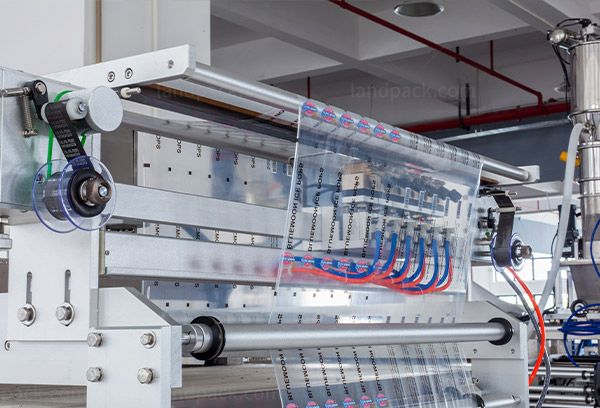

Multilane Liquid Juice Packing Machine | High Speed Sachet Packing Machine

Model : LDFS-720L-6

Application :

Multi-lane various flavors popsicle ice pop beverages sachet stick packing machine suitable for many kinds of liquid products, such as popsicles, lotion, ice pop, jelly, mouthwash, ketchup, flavoring, sauce, pasty, shampoo, salad dressing, cream, body wash liquid, and so on.

Application :

This high-speed 6-lane liquid packaging machine is ideal for manufacturers in:

Food & Beverage: Jelly, honey, sauces, syrups, condiments

Cosmetics: Shampoo, conditioner, lotions

Pharmaceuticals: Oral liquid, herbal extract

Daily Chemicals: Liquid detergent, liquid hand wash

Suitable for 3/4 side sealing sachet packing, depending on customization.

Kindly Reminder :

We have experienced team of R & D engineers who can customize packaging solutions according to your product characteristics.

Packing Exambers :

| Model | LD-480Y | LD-720Y | LD-960Y |

| Track Number | 4~6 Track | 4~10 Track | 4~12 Track |

| Filling Method | 1. Piston pump; 2. Peristaltic Pump | ||

| Capacity | Max.40 cycle/min | ||

| Sachet Size | L:45--120mm; W:35-60mm | L:45--120mm; W:35-90mm | L:45--120mm; W:35-120mm |

| Film Width & Thickness | Max.480mm;0.07-0.1mm | Max.720mm;0.07-0.1mm | Max.960mm;0.07-0.1mm |

| Sealing Type | 3/4 sides sealing | 3/4 sides sealing | 3/4 sides sealing |

| Cutting Type | 1. Straight Cutting; 2. Zig Zag Cutting; 3. Continuous Cutting | ||

| Air & Power | 0.8 mpa 0.8m³/min; 2.8kw | 0.8 mpa 0.8m³/min; 4.1kw | 0.8 mpa 0.8m³/min; 5.5kw |

| DIM & WT | 950*1470*1750mm; 300kg | 1153*1654*1750mm; 400kg | 1415*1686*2130mm; 500kg |

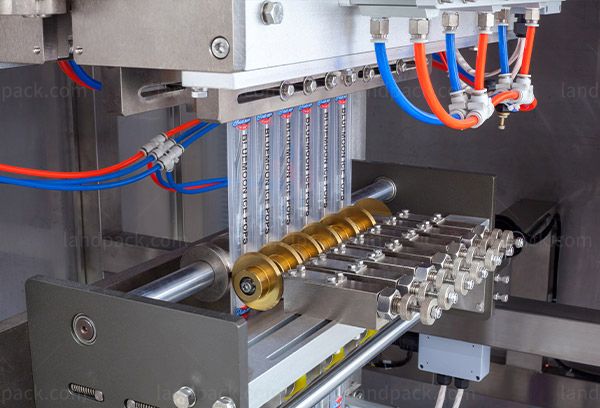

1. Operates 6 lanes simultaneously for high-speed production at 120-150 sachets per minute.

2. Handles various low-viscosity liquids including jelly, honey, shampoo, sauces and oral liquids.

3. Uses precise magnetic pump filling system for clean operation and minimal product waste.

4. Features servo motor control for accurate sealing and consistent bag formation.

5. Simple operation with Siemens PLC and touch screen interface showing real-time data.

6. Works with multiple film materials like PET/PE, OPP/PE and NY/PE for flexible packaging options.

7. Compact all-in-one design combines film feeding, coding, filling and sealing in minimal space.

We have many customer packaging case videos, please feel free to contact us to obtain your product packaging case videos.

Get Price & More Detail