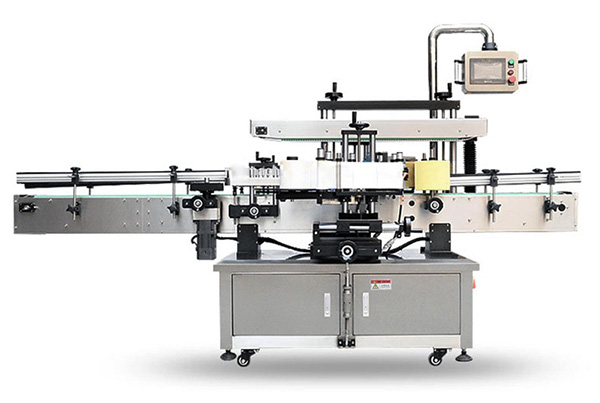

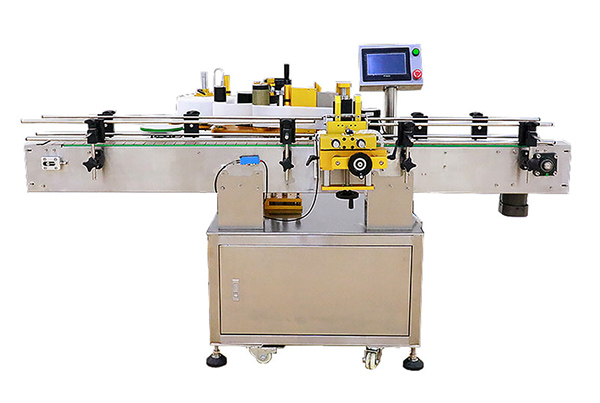

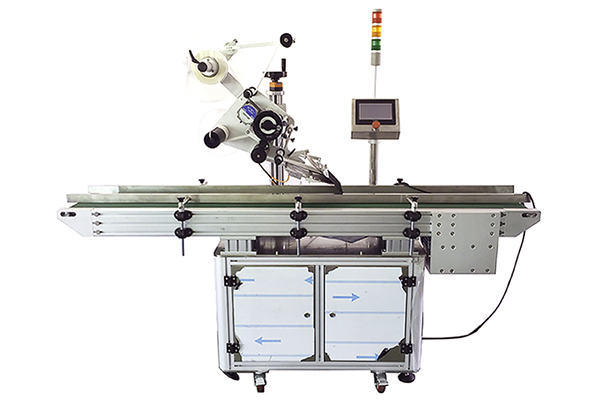

Automatic Positioning Round Bottle Labeling Machine

Model: LFT-YP-003

Introduction:

This automatic labeling machine is suitable for single-side or double-side labeling on round bottles. Adopting the way of positioning and labeling, it can label bottles accurately. This machine can be widely used in medicine, cosmetic, beverage, daily chemical industries.

Application:

Automatic positioning round bottle labeling machine(LFT-YP-003), it is suitable for automatic labeling of varous of round bottles in the pharmaceutical, daily chemical, food, chemical and other industries.

Applicable Container: all kinds of round bottles and jars

Optional Supporting Devices: Ribbon coding machine, thermal transfer coding machine, etc.

Attention:

This machine can work with automatic filling machine and capping machine, realizing automated production. Help to improve work efficiency. Please contact us if you need this. Thank you!.

Packaging Samples

Brief Introduction:

This machine adopts a roller labeling device. In the past, the labeling use a belt type. However, because the belt will deviate during the movement, which affects the accuracy of the labeling position, the roller type positioning method is used to completely eliminate the problem of the belt. Labeling position error caused by deviation.

Parameter:

| Model | LFT-YP-003 |

| Yield | 20-60 bottle/min |

| Bottle Diameter | Φ30mm-Φ80mm (customizable) |

| Maximum Label Width | 100mm (customizable) |

| Labeling Accuracy | ±1mm |

| Applicable paper roll inner diameter | Φ76mm |

| Applicable paper roll outer diameter | maximum Φ330mm |

| Control system | PLC |

| Power supply | 220V、50Hz |

| Airconsumption | 0.1m³/min |

| Dimension | 2000mm*800mm*1600mm(L*W*H) |

| Equipment Material | 304 |

| Weight | 250KG |

1. Applicable to the labeling of round containers in the pharmaceutical, daily chemical and other industries;

2. The biggest feature of this model is the use of roller type labeling, high precision and high speed;

3. This machine adopts a roller labeling device. In the past, the labeling use a belt type. However, because the belt will deviate during the movement, which affects the accuracy of the labeling position, the roller type positioning method is used to completely eliminate the problem of the belt. Labeling position error caused by deviation.;

4. The machine structure is simple, compact, easy to operate and maintain, a universal bottle separating device, no need to change parts for any diameter bottle shape, quick adjustment;

5. The labeling head can choose to use high-precision servo motors from world-renowned factories to control the labeling to achieve true closed-loop control and high-precision subdivision.

We have many customer case videos, please feel free to contact us to obtain your product case videos.

Get Price & More Detail