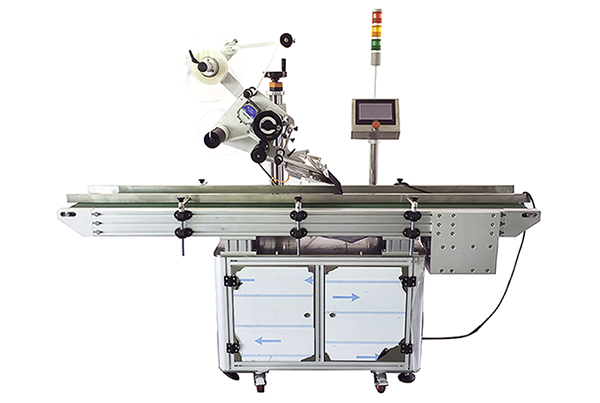

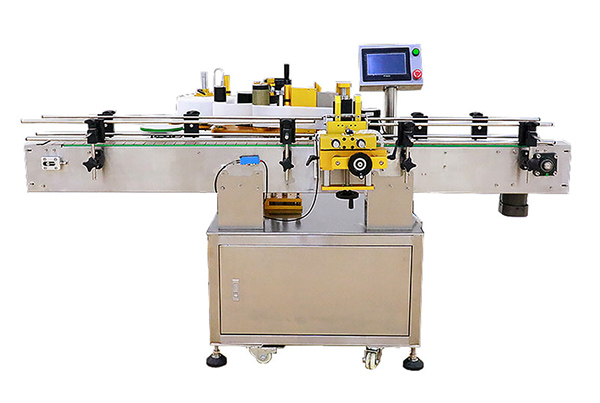

Fully Automatic Plane Flat Surface Paging Labelling Machines

Model: LFT-YP-P01

Introduction:

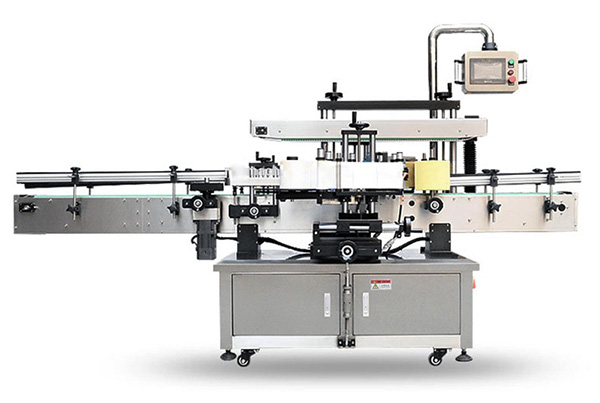

Suitable for all kinds of objects with plane surface, such as plastic paper card pouch cards hang tag paper plastic film flat surface products, boxes, bottles, cans, etc.

Application:

Fully automatic plane flat surface paging labelling machines(LFT-YP-P01), it is suitable for all kinds of objects with plane surface, such as plastic paper card pouch cards hang tag paper plastic film flat surface products, boxes, bottles, cans, etc.

Packaging Samples

| Technical Parameters | Applicable scope | Technical Parameters | Applicable scope |

| Applicable labels | Length:6mm~250mm | Applicable product size | No request(Depending on pipelining parameters) |

| Width:6mm~130mm | |||

| Outside diameter(mm):φ280mm Inner diameter(mm):φ76mm | |||

| Labeling speed | Step forward:40~150pcs/min | Power | Traction step:380W |

| Servo:50~200pcs/min | Traction servo:830W | ||

| Labeling accuracy | ±1mm | ||

| Weight | About 180kg | Applicable power supply 220V | 220V 50HZ |

| Equipment size | (length×width×height)1100mm×700mm×1450mm | ||

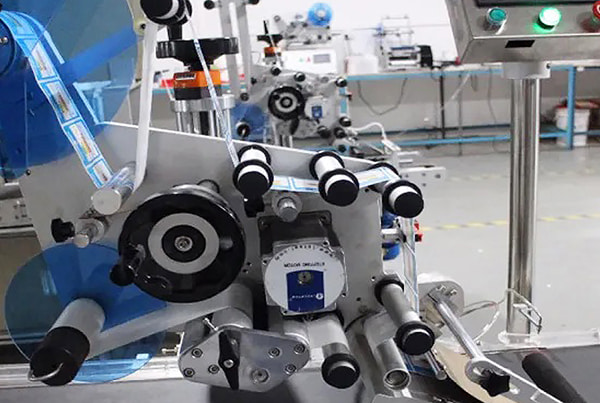

1.With stable paging, the card sorting rate is much higher than that of the general card sorting mechanism.

2.High paging labeling speed, with the monitoring code for the medicine box, the stable speed can reach more than 100 pieces/min.

3.It is widely used and can be used to label all kinds of CARDS and CARDS.

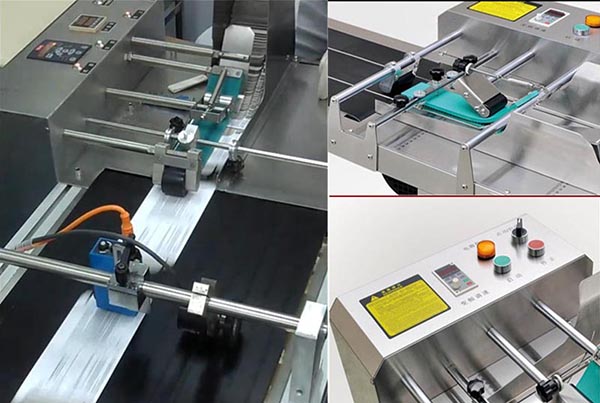

4.Stable labelling accuracy, using pressure top roller to press the workpiece, conveying steady, no warping, ensure the accuracy of labelling;

5.The mechanical adjustment part structure combination and the smart design of label winding, 6 degrees of freedom of labeling position fine adjustment is convenient, so that the conversion between different products and label winding become simple and time-saving;

6.Intelligent control, automatic electro-optical tracking, with no object and no label, prevent label waste;

7.High stability, panasonic PLC+ dimensional control touch screen + panasonic needle electric eye + lait/titis label electric eye advanced electric control system, supporting 7X24 hours operation of equipment;

8.It has the function of fault prompt, production count, power saving, production number setting prompt and parameter setting protection;

9.Optional function: hot stamping/spraying code, automatic feeding and automatic receiving.

We have many customer case videos, please feel free to contact us to obtain your product case videos.

Get Price & More Detail