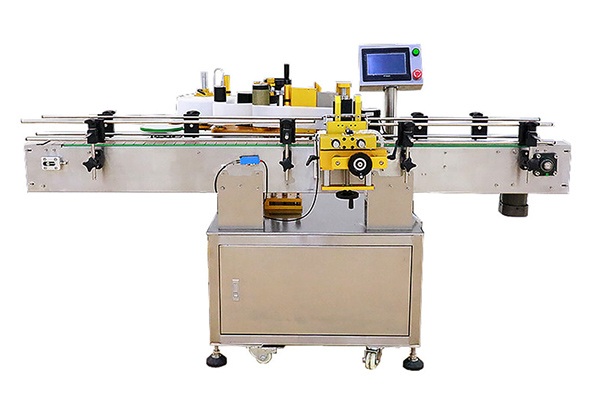

Automatic Round Bottle Dual Servo Driving Labeling Machine

Model: LFT-YP-130

Introduction:

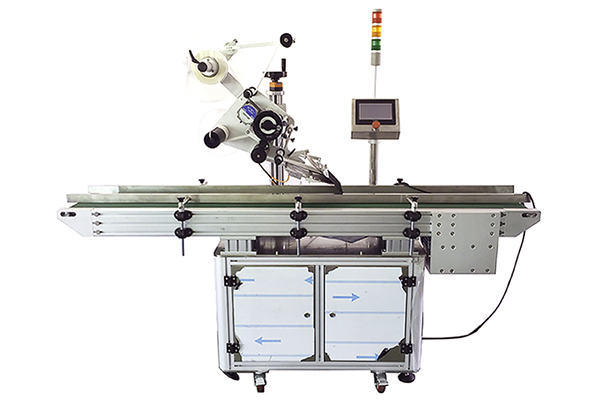

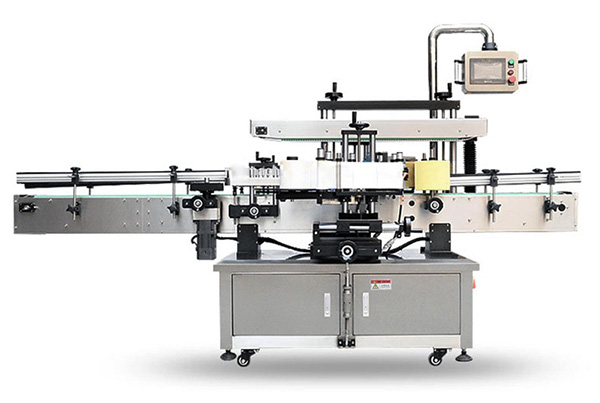

Suitable for product in round shape for single, double or located labeling. It can be a justed for cone-shaped prouducts. It can be used individually or attached to assemble line. It is widly used with beer bottle, beverage bottle, shampoo and comestic.

Application:

Automatic round bottle dual servo driving labeling machine(LFT-YP-130), it is suitable for product in round shape for single, double or located labeling. It can be a justed for cone-shaped prouducts. It can be used individually or attached to assemble line. It is widly used with beer bottle, beverage bottle, shampoo and comestic.

Filling container: all kinds of round bottles and jars

Optional Supporting Devices: Ribbon coding machine, thermal transfer coding machine, etc.

Attention:

This machine can work with automatic filling machine and capping machine, realizing automated production. Help to improve work efficiency. Please contact us if you need this. Thank you!.

Packaging Samples

Model | LD-TB130 |

labeling range | L<300mm,H<120mm |

Labeling speed | 60 bottle/min |

Labeling accurancy | ±1.5mm |

Size of main frame | L1900*W800*1450(mm) |

Working voltage | 220V |

Electricity power | 420W |

Weight | 250KG |

Packing Dimension | 2100(L)*1150(W)*1450(H)mm |

1. Good labeling performance, label is flat with wrinkle.

2. Inteligent control, automatic photoelectric tracking with la be-ing, no objects no labeling.

3. Easy adjustment, labeling speed and conveying speed and bottle allocation speed can be adjusted steplessly.

4. Simple structure in linear type ,easy in installation and maintation.

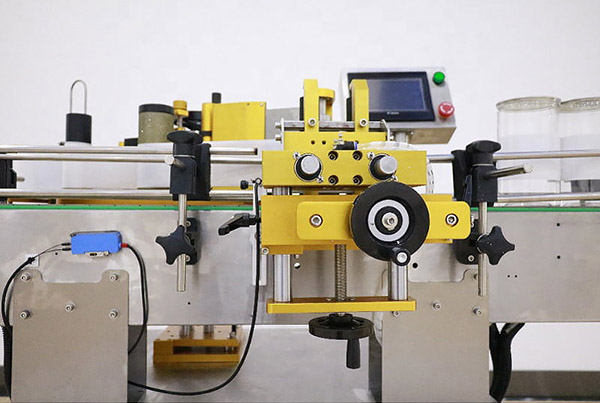

5. Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

6. High pressure double crank to control the die opening and closing.

7. Running in a high automatization and intellectualization,no pollution.

8. Apply a linker to connect with the air conveyor ,which can directly inline with filling machine.

We have many customer case videos, please feel free to contact us to obtain your product case videos.

Get Price & More Detail