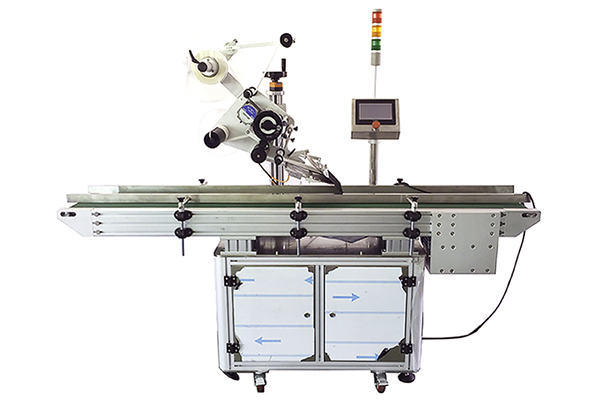

Full Automatic Round Bottle Labeling Machine

Model: LFT-YP-002

Introduction:

Applied to the round bottle labeling of industries such as pharmacy , food , daily chemical and the like , and can be pasted with a full - circumference label and a semi - circumferential label.

Application:

Applied to the round bottle labeling of industries such as pharmacy , food , daily chemical and the like , and can be pasted with a full - circumference label and a semi - circumferential label.

Filling container: all kinds of round bottles and jars

Optional Supporting Devices: Ribbon coding machine, thermal transfer coding machine, etc.

Attention:

This machine can work with automatic filling machine and capping machine, realizing automated production. Help to improve work efficiency. Please contact us if you need this. Thank you!.

Packaging Samples

Brief Introduction:

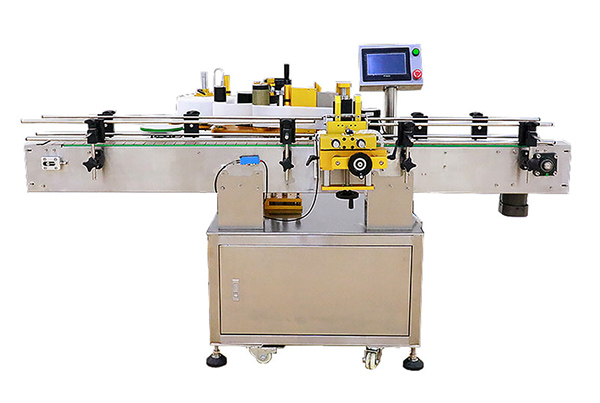

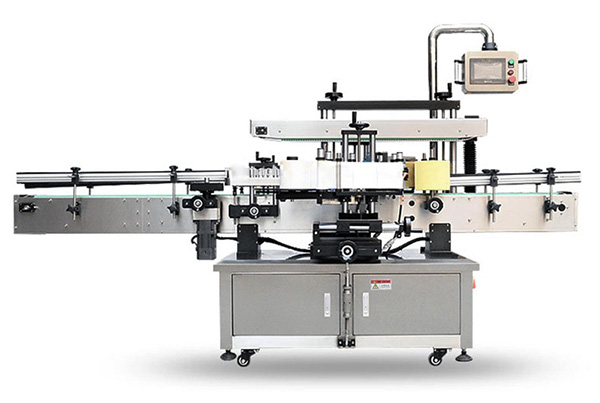

1.Optional automatic rotary bottle uncrambler machine, can be directly connected to the front production line, automatic bottle feeding into the labeling machine, increase efficiency.

2.It can be equipped with ribbon printer machine, which can print production date and batch number on line, reduce the packaging process of bottle and improve production efficiency.Parameters of labeling machine.

Parameter:

Machine model | LFT-YP-002 |

Supply Power(V/Hz) | AC 220/50 110/60 |

Power | 1000w |

The application of bottle (mm) | Outer diameter12-100mm Height30-200mm |

The application of label (mm) | Height15-100mm Length20~300mm |

Production speed(bottle/min) | 20-50 (Depends on bottle size) |

Dimension(L×W×H)(mm) | 2000×800×1650 |

Net weight(kg) | 300 |

1. Wide application range, can meet the full-circle labeling or semi-circle labeling of round bottles, easy to switch labeling between bottles, easy to adjust;

2. The label has a high degree of coincidence. The label is bypassed by a rectifying mechanism. The label is not deflected. The labeling position is x/y/z and the inclination is adjustable. The total of eight degrees of freedom is adjustable.

3. Excellent labeling quality, adopting elastic pressure-coated belt, flat labeling, no wrinkles, and improve packaging quality;

4. Flexible application, bottle standing labeling, automatic bottle splitting function, can be produced in a single machine, or can be connected to the production line;

5. Intelligent control, automatic photoelectric tracking, with no material and no labeling, no automatic calibration and automatic label detection to prevent leakage and label waste;

6. High stability, Panasonic PLC + Panasonic touch screen + Panasonic needle-shaped electric eye + German labor test label electric eye composed of advanced electronic control system, support equipment 7 × 24 hours of operation;

7. Simple adjustment, labeling speed, conveying speed and bottle dividing speed can realize stepless speed regulation and adjust according to need;

8. Rugged and durable, adopting three-bar adjustment mechanism to make full use of the stability of the triangle, the whole machine is solid and durable. Made of stainless steel and high-grade aluminum alloy, in line with GMP

We have many customer case videos, please feel free to contact us to obtain your product case videos.

Get Price & More Detail